I would like to show you one of the projects I did for a customer, 3 full-scale flamingos from Disney Alice in Wonderland classic animated movie. They were going to be displayed in the children's hospital along with other projects I did for the same person. After I shipped them, I got news from a few people, that they were able to buy the pieces I did on Ebay for much more than I charged. Based on that, I am not sure, what will happen with them. I was angry for a short while that they did not serve the purpose but the silver lining is, I met this way 3 very nice collectors.

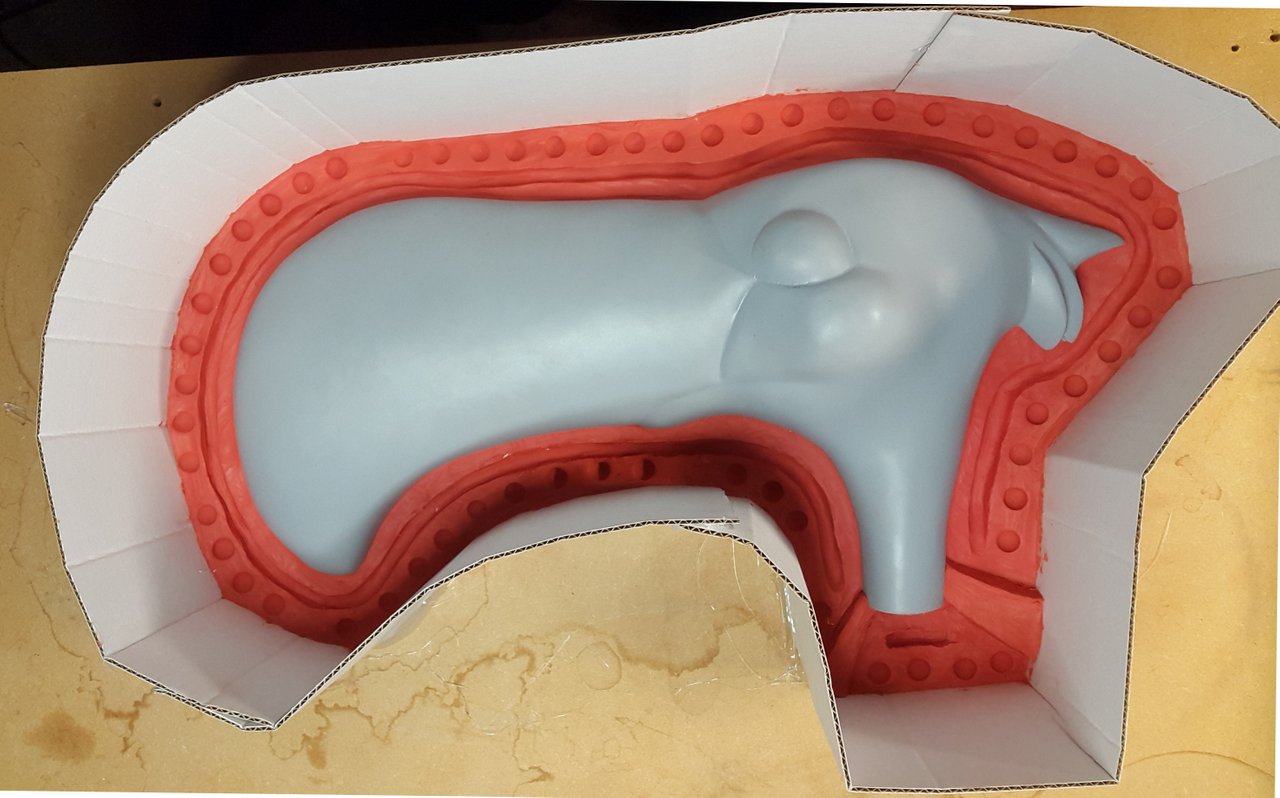

I took this project knowing there will be 3 color versions, so I need to make molds to produce multiple copies. I underestimated how big and heavy the molds will be and how expensive the silicone required will be. At least I reduced the amount of material for casting the pieces. I broke the figure to 3 pieces, head, neck and body for easier casting. I used a process called rotocastinIt requires much less resin and is perfect for big pieces like this. I poured half of cup of mixed resin to the mold and move the whole thing around to let the fluid flow to all areas creating a thin layer of plastic. I repeated the process 4 times to build up the walls. It was quite an exercise because each of the walls weight few kilos and I could not stop for a few minutes to avoid setting resin in one place.

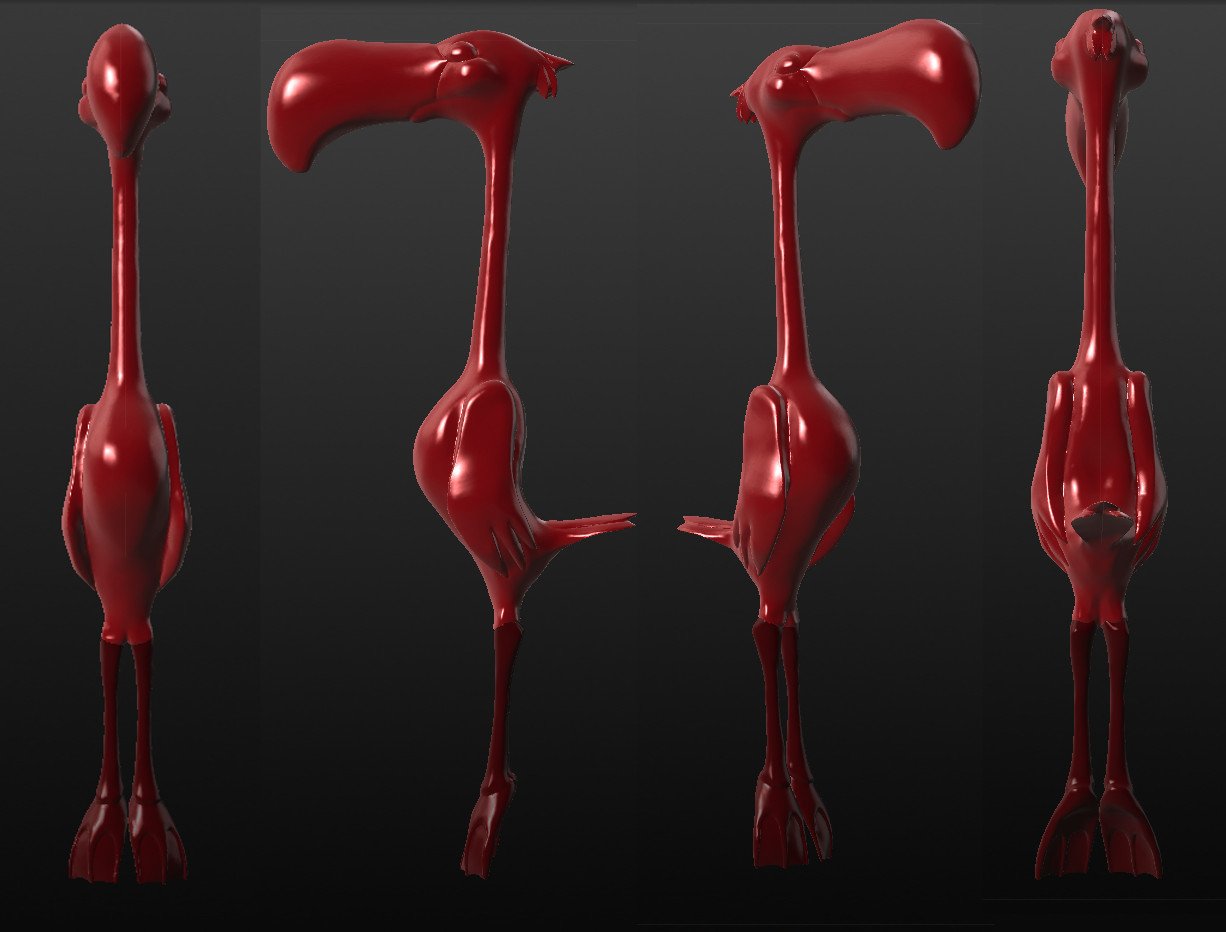

The prototype was made using my small 3d printers. I sculpted the model using Sculptris and then made it hollow in Meshmixer. I then cut it to many small sections which could fit on my 3d printer. I glued them all after printing. I knew that walls just 2 mm thick will be very fragile while sanding, so I filled the model with rigid polyurethane foam. It permanently glued everything without adding extra weight. I could then use all the required techniques to make it smooth and hide joints.

The whole model is big and areas easy to access with a sander. I used machines as much as I could to speed the process. It still required a lot of hours of filling and sanding with multiple coats of primer in between. I used car body filler for bigger holes and green stuff for small imperfections. Since then I discovered the inexpensive wood filler which works very well with PLA. I sued it to fill huge areas on my BB9E project and the did not crack or fall off yet.

For painting, I used sprays to get solid and vibrant colors. It required some masking but not too much. My biggest worry at this stage was, how to ship it securely. I decided to leave the legs apart to reduce the size of the box. I put each model on a rigid cardboard tray and secured it with lots of foam pieces hot-glued to the tray. The bird could not move in transit and stack of 3 reinforced the cardboard box side walls. It worked!

I learned many new things while doing this project like dealing with the scale and challenges of shipping heavy but delicate objects. I hope this will bring smiles to sick children as intended and not land on Ebay again. If you see that for sale somewhere, let me know here or at http://themodelmaker.net/ so I can take action. I only took this commission because of that and my price did not reflect the amount of work I spent building them. This is another lesson for me. I will probably cut the molds and recycle them in my other projects at some stage but if you want a copy, send me an email or comment through my blog. This and many other fantastic animals from Alice in Wonderland can be found here: https://themodelmaker.net/alice-in-wonderland-creatures/

Thank you for reading and your support.