In the rapidly evolving field of manufacturing, accuracy and productivity are critical. Making sure every product satisfies exacting quality requirements can be a difficult undertaking. This is the application of cutting-edge technologies such as **autofocus Camera **s. These cameras are transforming quality control and inspection procedures because they have the capacity to automatically change their lenses' focus to focus on objects at different distances. We will look at how autofocus cameras are changing production, enhancing quality assurance, and expediting inspection procedures in this blog.

AutoFocus Cameras' Place in Contemporary Manufacturing

Improving Quality Control with AutoFocus on Cameras

Quality control is an essential component of production since it ensures that products meet specifications and are error-free. Traditional quality control methods frequently include manual inspections, which can be laborious and prone to human error. Still, this procedure has been greatly improved by the advent of cameras with autofocus.

AutoFocus cameras are able to precisely and swiftly focus on various product components, producing high-resolution photos that make even the smallest flaws visible. Because of its accuracy, manufacturers can detect problems early on and take immediate action, which lowers the possibility that faulty goods will be sent onto the market. Manufacturers may cut waste, increase product reliability, and maintain consistent quality standards by automating the inspection process.

Advantages of AutoFocus Cameras for Inspection Procedures

Inspection in an industrial process involves closely inspecting items to look for flaws, irregularities, and other problems that can compromise their performance or safety. Using autofocus cameras has the following advantages:

Enhanced Accuracy: AutoFocus cameras have the ability to focus on certain regions with extreme precision, resulting in finely detailed photos that expose flaws that are unseen to the unaided eye.

Speed and Efficiency: These cameras have the ability to quickly change focus between various product components, allowing for quicker inspections without sacrificing accuracy.

Consistency: By removing variances that could arise with manual inspections, automated systems employing autofocus cameras guarantee consistent inspections.

Data Collection and Analysis: Recurring problems can be found, trends can be followed, and procedures can be gradually improved by storing and analyzing the high-resolution photos taken by autofocus cameras.

Automating Production using AutoFocus Video Systems

AutoFocus Camera Systems Implemented in Production Lines

To guarantee their efficient use, autofocus cameras must be integrated into manufacturing processes through a number of steps. Here are some crucial things to remember:

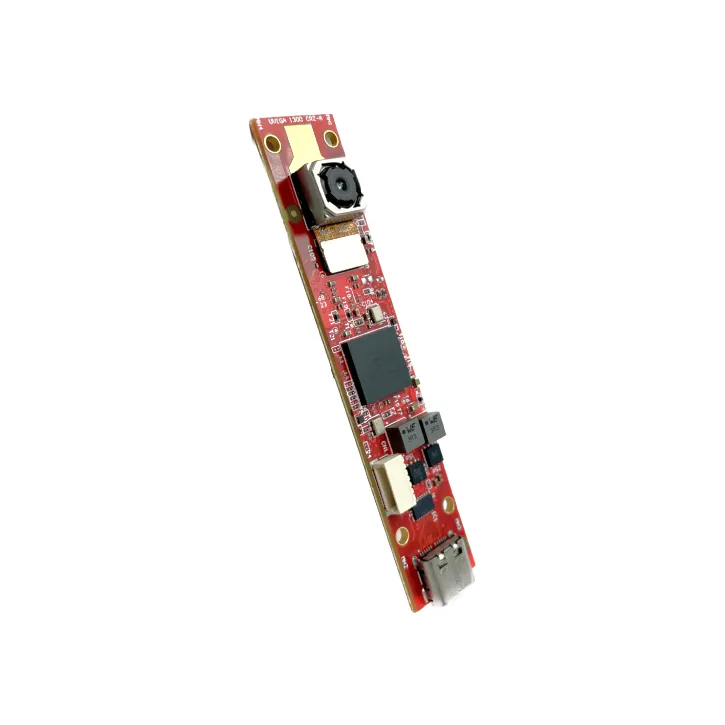

Choosing the Correct Camera: Pick an autofocus camera that is appropriate for the demands of your production process. Take into account elements like resolution, focus speed, and system compatibility.

Appropriate Location: To capture important inspection areas, place the camera autofocus systems strategically throughout the production line. Make sure they can see the places that require inspection clearly.

Integration with Software: Make use of software that can analyze the photos that the cameras take and, in the event that flaws are found, set off alarms or take other appropriate action. It should be possible for this program to interact with other systems on the assembly line.

Instruction and upkeep: Educate employees on how to use and maintain the autofocus camera systems. Frequent maintenance guarantees that the cameras continue to function at their best and produce accurate images.

Overcoming Implementation Challenges with the AutoFocus Camera

Even though autofocus cameras have many benefits, there may be difficulties in manufacturing them. Successful integration depends on addressing certain issues:

Initial Cost: Autofocus camera systems may require a sizable upfront investment. Nonetheless, the expenses are frequently covered by the long-term gains in terms of enhanced quality control and decreased waste.

Complexity: It can be difficult to integrate cutting-edge camera systems with current production lines. One way to lessen this problem is to work with seasoned vendors and make sure staff members are properly trained.

Environment: Dust, vibrations, and uneven illumination can all be found in manufacturing settings, which can be harsh. These difficulties can be addressed by selecting sturdy cameras and making sure they are well maintained.

Case Studies: AutoFocus Camera Integration Success Stories

Automobile Production

In the car industry, accuracy is essential. To inspect engine components, an automotive manufacturer incorporated autofocus cameras into their production line. The cameras significantly decreased the number of defective products and warranty claims by identifying minute flaws that were previously missed.

Manufacturing of Electronics

Circuit boards were inspected by autofocus cameras employed by an electronics manufacturer. The detection of soldering flaws and misalignments was made possible by the cameras' capacity to focus on tiny, complex components. Customer satisfaction and product dependability both increased as a result.

Future Directions for AutoFocus Camera Innovation

Improvements in Camera AutoFocus Features

It is anticipated that autofocus cameras will go much further as technology progresses. Among the anticipated trends are:

Enhanced AI Integration: Defect identification and process optimization can be further enhanced by combining artificial intelligence (AI) with focusing cameras.

Greater Resolutions: As camera resolutions continue to advance, even more accurate examinations will be possible.

Connectivity and IoT: By combining the Internet of Things (IoT) and autofocus cameras, more proactive quality control procedures can be implemented through real-time data processing and monitoring.

In summary

The incorporation of ** AutoFocus Camera **s into production procedures is transforming inspection and quality control systems. With the unmatched accuracy, speed, and consistency these cameras offer, producers can cut waste and uphold high standards of quality. Manufacturers can fully utilize autofocus cameras to increase productivity and optimize operations by overcoming implementation issues and keeping up with technical improvements.

With autofocus cameras, you can embrace the manufacturing of the future and advance your quality assurance and inspection procedures.

** Click To Know More **