Your local friendly cab mount support, which has went off on its own and rusted itself through. Making us have to work more...

I had to cut the top of the pad out and began to size and shape a piece of steel to make a new surface.

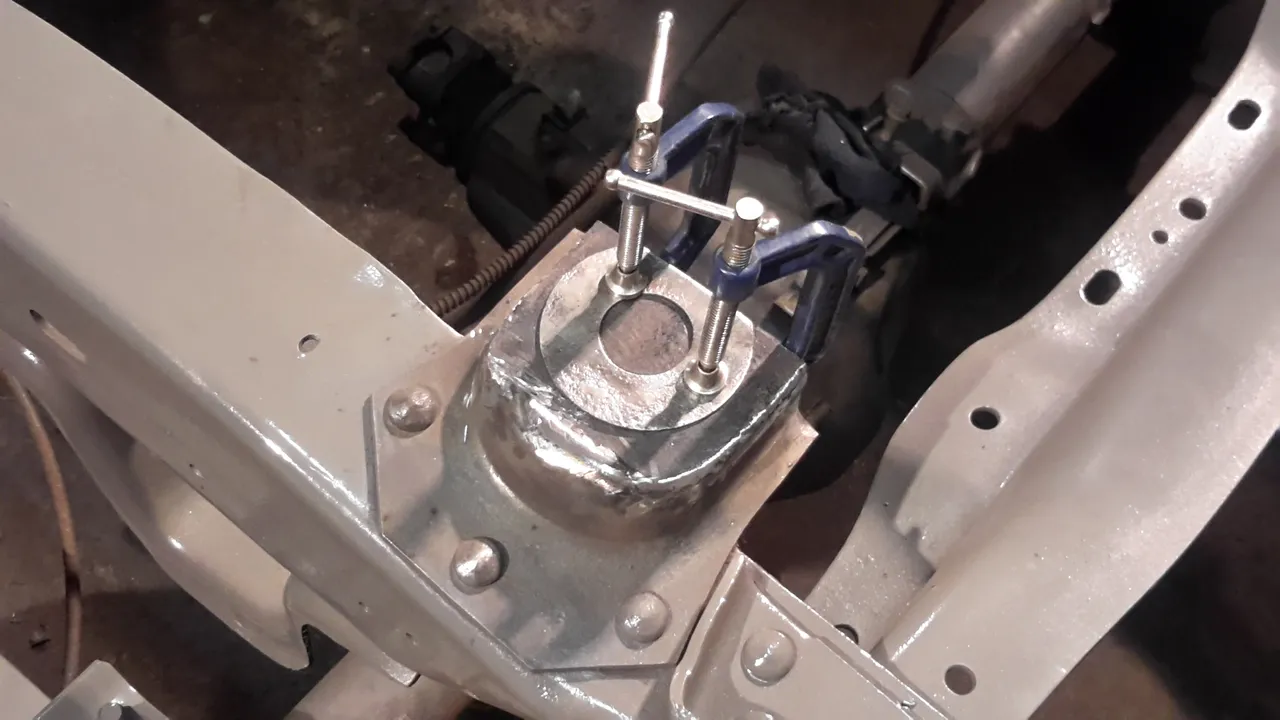

Finished shaping the steel and welded it in place. Upon checking, I found the new pad sat a little uneven with the otherside.... Uh oh.

I found a washer with the exact diameter hole I needed to make in the pad anyways, so I used it as a shim and a handy cutting guide. This is not how I wanted it to come out, but sometimes you have to make do with workarounds.

It appears I'm not the best at welding circular beads!

I had to cut the hole out, which I don't currently have pictures of. I plan on filling the gaps on the pad so water cant collect there and prematurely rot this mount back out. I have two parts orders on the way which will enable me to get into much more interesting steps on the chassis work, stay tuned.