And so the journey can continue. My spindle/router arrived two days after the cnc-frame and so I could get on with doing my first job.

The very first job could have been done without the spindle since the tradition is to mount a feltpen and use the shapeoko as a very slow and expensive printer.

I could not find a good way to secure the pen directly to the holder so i chose to wait (it might have been a factor that I didn't have time as well)

I got a video of the world-changing event here:

After that I decided to go ahead and do my first actual carving operation and to stay on the safe side I did a very simple setup.

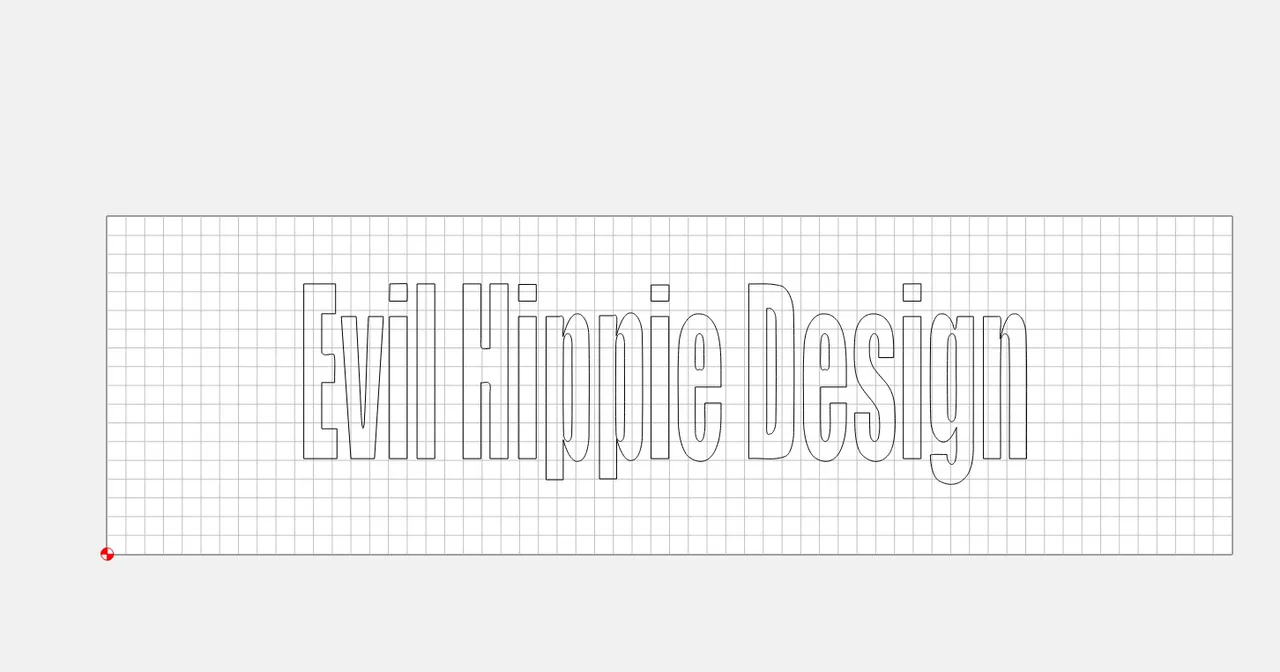

I started up carbide create which is a 2.5D cad/cam program that is freely available and exports gcode directly. The simplest, yet still interesting thing I could think of was to write my company name in inkscape and do what is called a v-carve of that in foam.

v-carving is when you use a v-shaped carver and the cnc-mill controls the width of your design by plunging the bit deeper into the material.

I chose it because it is easy to setup and still has a fairly nice result.

this is what it looks like after importing an svg file made in inkscape into carbide-create.

and this is what it looks like with the actual path drawn. You cannot see the width here but it is all fixed automatically so thats very nice.

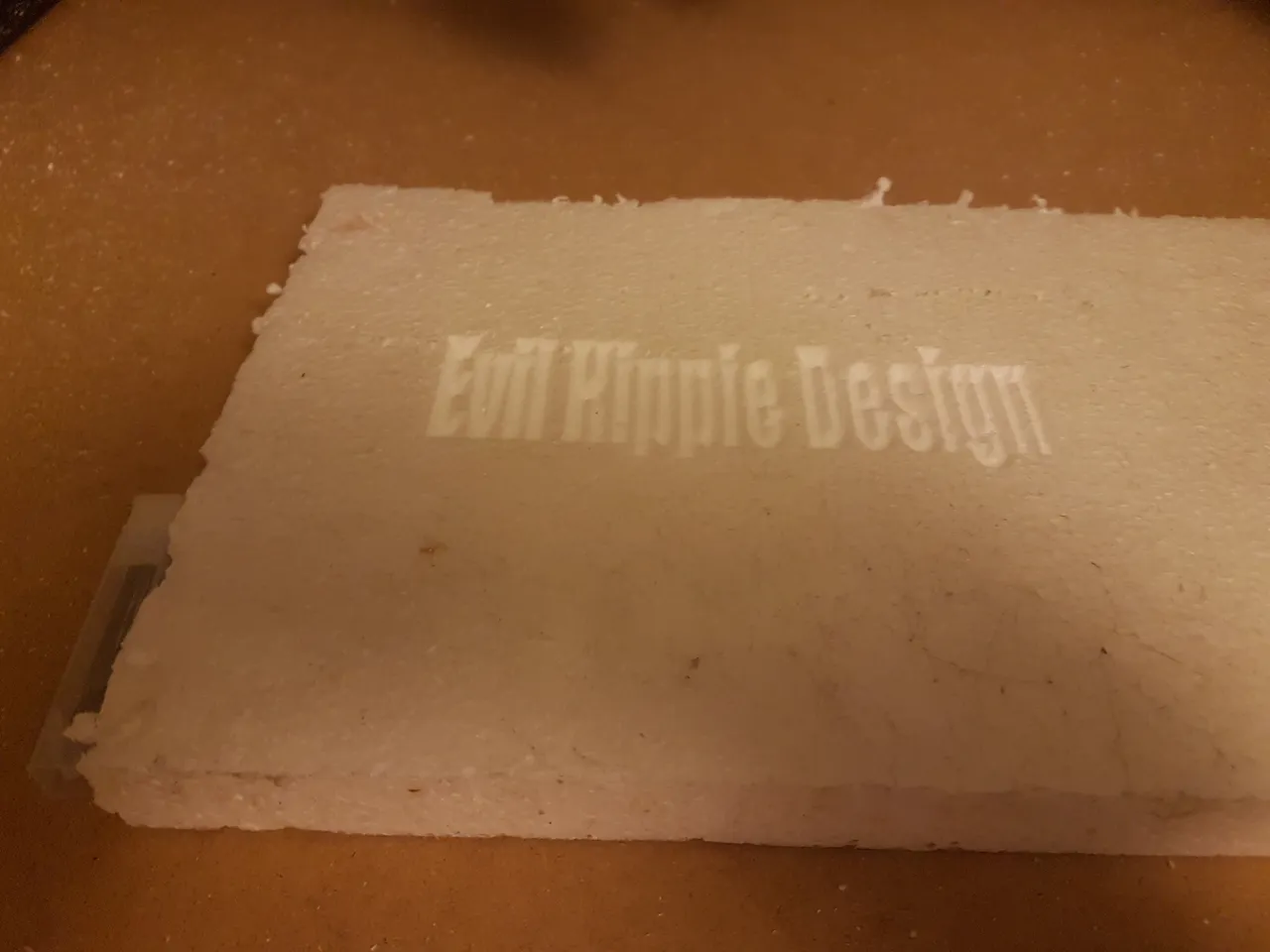

I put a piece of foam board in there with doublesided tape , zeroed the mill (always remember to zero the mill) and let loose

Zeroing the mill means you manually jog the router so that the bit is situated over what is origo on your cad drawing. In this case I chose the lower left corner (denoted by the little red checkered circle in the corner) the mill will run relative to that point whether there is material or something else, until its limits so stuff can go catastrophically wrong if you are not careful.

BTW you need to zero the z-axis as well and again if you have miscalculated the thickness of your material the bit will dig into the bottom of the mill. Thats why the plate in the bottom is called a wasteboard and is made from easily replaceable mdf plate.

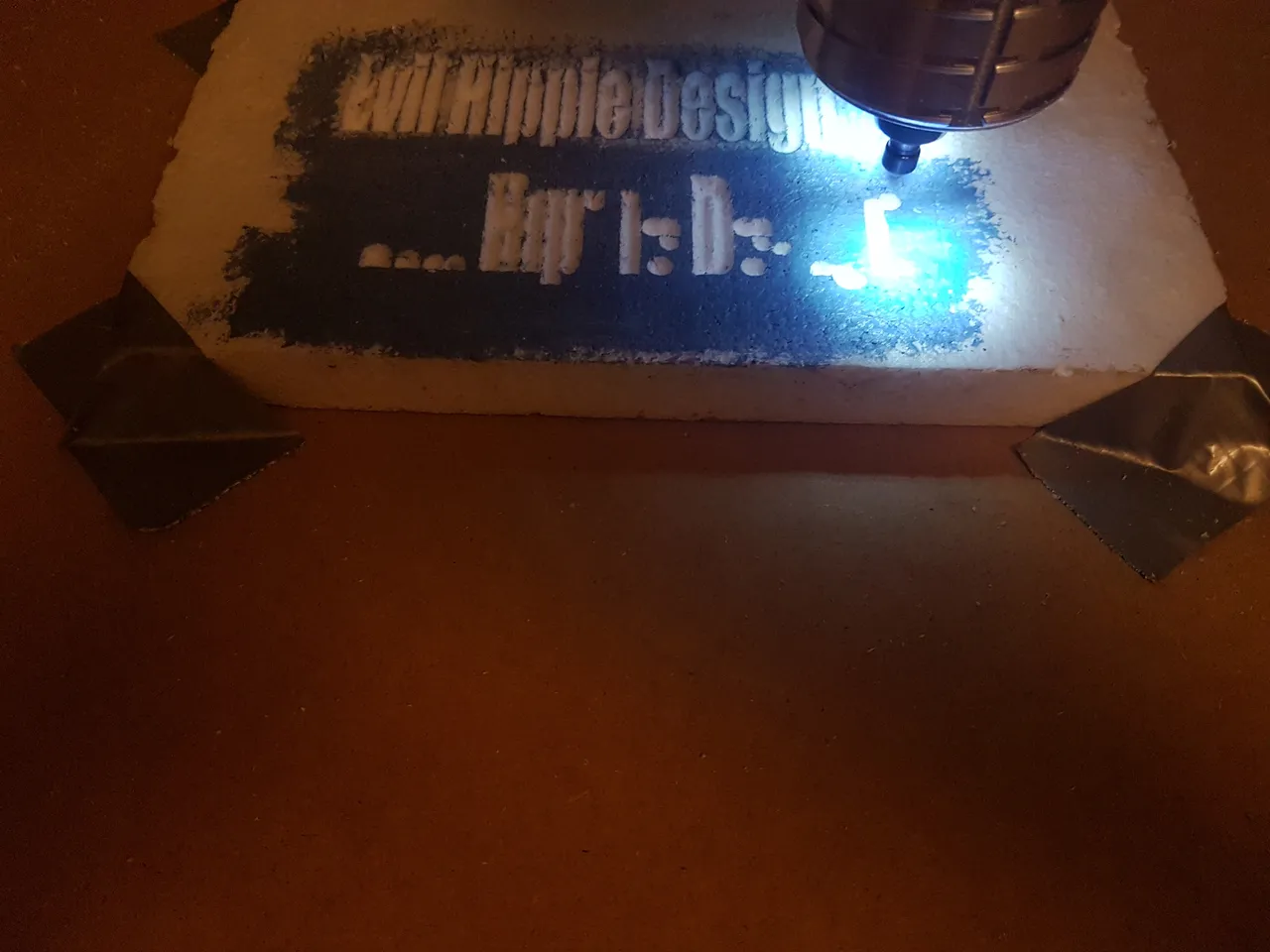

Well as you can see i managed to not destroy anything and I got a nice result. I made two versions because it was kind of hard to see the result in the white foam so I did another where I painted the surface first. it helped a little but not alot.

next on my todo list was to buy some proper router bits and some collets to hold them, also I needed to find a software that supported real 3d milling. Otherwise I wouldnt be able to do all the projects I had bought it for in the first place.

Whether I succeded in this must wait until another post. Now i need to go make some food for my family. Until then, cheers.

Im EvilHippie, a compulsive creative and jack o' trades. If you want to know more about me, check out my introduction post here

If you like what you see, feel free to upvote, follow and resteem

or you can check out my accounts on these sites:

Your'e welcome to like or follow me there as well.