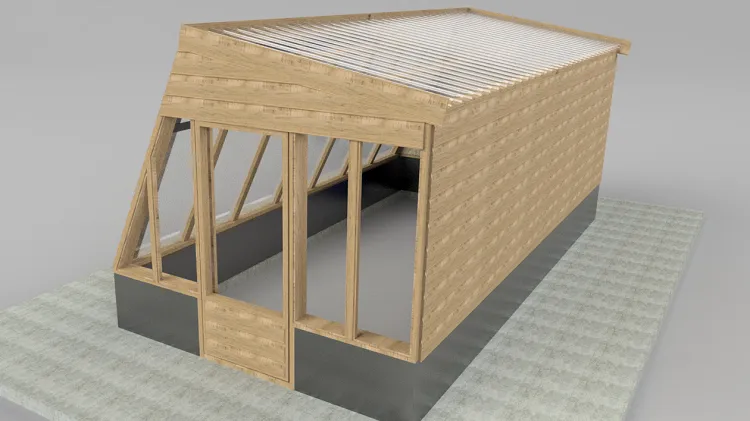

Well it's been over a week since the last update, so i think it's about time i post where its at. I can see the finish line rapidly approaching on the design aspect of this project as i only have a few albeit complicated bits left to plan for

Catch up below

Left to do

Design the door- Improve the structure around the roof to make it stronger

- Work in a load of vents

Plan how the door end will be glazed- design the interior for maximum space

- (Added)

Finish the cladding

I’m sure you’d agree that its starting to look like a finished product and this is really starting to help assess how i can go about implementing this build, both from a budget perspective and logistical

The door

Will I’ve done the bulk of the door the only thing left to do is to sort the glazing in it, problem is the doors width is more than the standard polycarb twinwall width (i could buy a custom sized bit but that'll cost more, i'm thinking of adding in a large opening vent or louvres or worst case just turn the polycarb sheet 90 degrees (i want to avoid this as my OCD will freak)

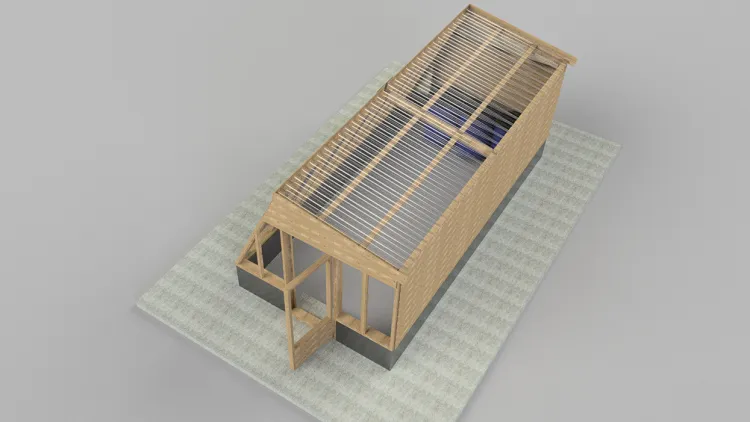

The roof

I'm not sure how to approach this to be honest, how strong does it need to be? The roofing sheet is light as its plastic, it doesn't need to hold body weight etc.

The back and two sides will be very strong due to the design used, so im hoping a minimal structure for the roof is needed to keep the cost down, i will try to design it in a way that can be reinforced if needed, retrospectively with minimal effort/cost

Ventilation

This is a big ole one as if i stuff this up either to little or two much it could have a negative impact on the output.

Granted it's far better to have too much ventilation, but from a building/budget point of view i want to get it right.

So this is the next big focus…

Proud member of the Global Homestead Collective

Upvotes, resteems and follows are great and truly appreciated. However a meaningful comment is worth so much more, don’t be afraid to say hello. Until next time, all the best DigitalDan