A common problem and constant battle for reloaders is tiny spent primers hiding in cracks, jammed into our tools, and generally creating a mess when we remove them from fired cases. Reloading equipment manufacturers have attempted to mitigate this problem with various designs, but as with all things they must decide what to give up in order to gain something else. For instance, it is plausible to design a press that never allows a single primer to go flying, but this may limit its ability to facilitate on-press priming tools. Alternatively, they may choose to include on-press priming tools, but at the expense of less than perfect spent primer disposal.

Below are two images showing the ram of the Redding Big Boss II reloading press. The left image shows the cutout that is tooled into the ram to facilitate the on-press priming tools that are available from Redding. The image on the right show the basic priming attachment that comes with the press, but the cutout also facilitates the use of the Redding Slide Bar Automatic Primer Feeding System.

The problem that arrises from having this cutout in the ram is that when the decapper pin of your sizing die pushes out the spent primer, rather than the primer dropping down the ram and out the tube attached to the bottom as designed, it comes flying out the cutout. If you are lucky it lands on the press. Most times it lands on the floor. An additional problem is that spent primers are dirty, very dirty. The carbon residue left in the primer will find its way out the cutout in the ram and make a mess of things.

In order to prevent these problems I have been pushing a small piece of crafting foam that I bought from the hobby supply store into the cutout. While this works, it is less than ideal. What I envisioned was a fabricated part designed specifically to fill this cutout. Recently I happened across a fellow reloader that has created a Facebook page entitled LoaderTools where, among other things, he sells a Primer Director fabricated with his 3D printer.

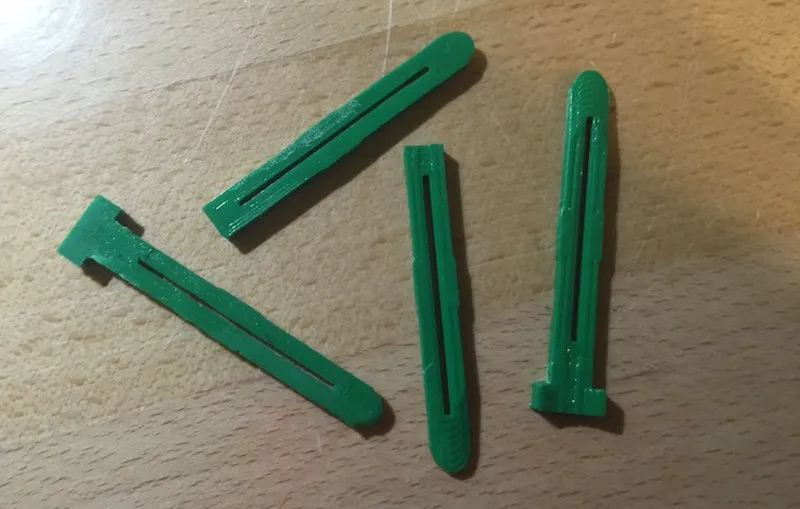

Below are a series of three images. The two images on the left show the shorter style primer director that does not fit in directly behind the shell holder. The image on the right shows the longer primer director with a "t" fabricated on the top that slides in behind the shell holder. The advantage of the shorter version is that it allows the shell holder to be inserted and removed without removing the insert. The advantage of the longer version is that it fits more tightly into the cutout which makes it less likely that it will fall out, or worse yet, fall down the middle of the ram.

I have to say that I am extremely pleased with this solution. Frankly, something like this should be included with every press. I did notice that the shorter version of the tool is more narrow than the longer version by about .010". I assume this is a normal variation, but I like the tighter fit. I am considering attempting to cut the top off of one of the longer Primer Directors in order to make a tighter fitting short insert that does not inhibit insertion and removal of the shell holder.

If you are interested in purchasing a Primer Director or one of the other parts Chris prints (including primer catching systems for the RCBS Rock Chucker and Primer Directors for Lee presses) you will need to join the LoaderTools group on Facebook. His service and shipping are great, and his prices are frankly too low.