maybe all automatic motorcycle users often experience damage to the roller housing like this, this is actually not damage caused by the components themselves, but most of the damage in this area is caused by the lack of attention from the motor users themselves,

almost 80% of the damage was caused by a dirty CVT chamber and a leaky crutch axle seal.

If the components on this CVT are damaged or have started to wear out in some parts then things like this will cause several symptoms, the most common of which is an abnormal sound or sound outside the sound that should be generated

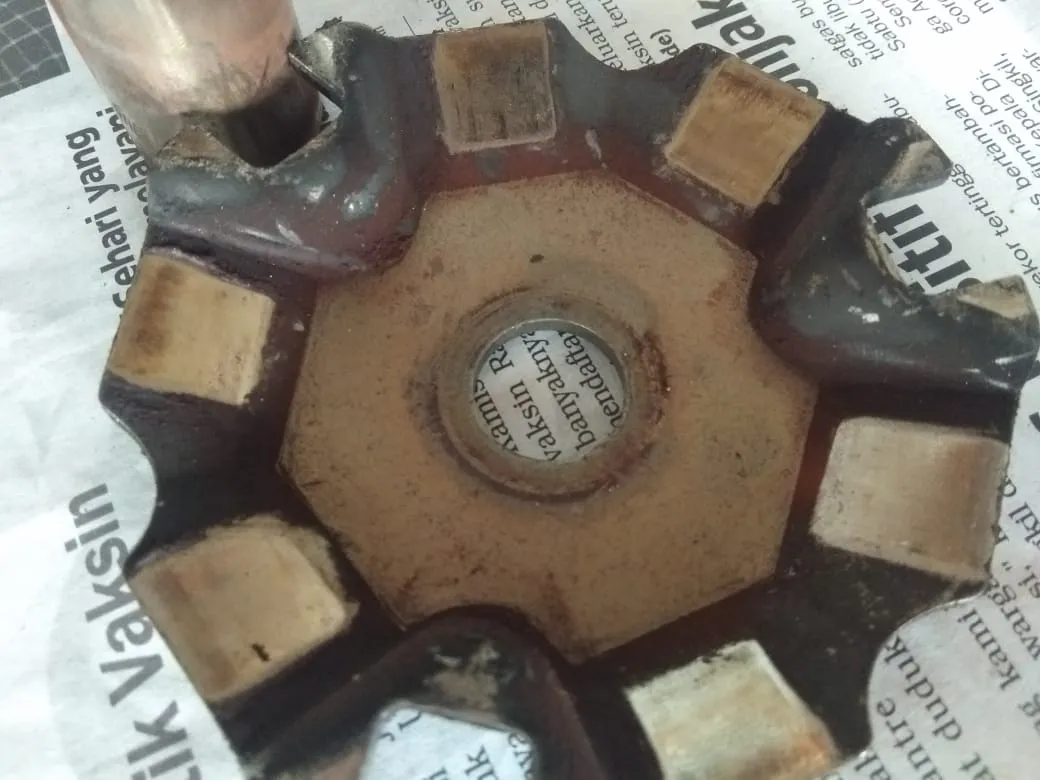

Roller House

Roller housing, is the path where the roller moves. The roller housing will wear out over time if most of the dust gets inside. If the roller housing is worn, the result is that the gas pull feels very heavy and also causes a sound in the CVT tub. Most of the causes of damage to the roller housing will quickly wear out if the behavior when driving, or the load when driving is excessive. To protect the roller housing from wearing out quickly, grease the roller groove and the roller housing bus, but don't overdo it if excessive so one of the causes of its own damage.

Rollers

Problems that cause rollers to break or break that often occur, This symptom is indicated by the sound of crackling sounds in the CVT section, Rollers that are damaged or wear faster can be caused by improper driver behavior, and on the roller track dirty, To avoid damage like this is very easy, you just need to do regular service for 3 to 4 months, and apply grease to the roller.

The bushing or known as the roller housing BOS is also very fast in getting heat from the engine and the friction is very, very high. Thus, the performance of these two parts can also be said to be very heavy and prone to damage.

For Honda brand automatic motorcycles, there is no place or space for grease, such as Yamaha motorcycles which have a small space or path for their own grease, so Honda motorcycles are very prone to damage because there is no special lubricant or lubricant line in it.

This part should also be checked by opening it like a CVT and by feeling whether there is sideways movement or not.

If the bushing or BOS moves sideways or obliquely, it can be ascertained that the bushing is worn.