Well Hello There Fellow Technicians And Hivers

These damn Renault's again.

Now as a technician I can say and have the right to say that these cars are just utterly bad to work on, I've got other words but I'd rather not use them.

Don't get me wrong it's a neat little car, very neat in-fact but it's a pain to work on.

The reason for this is because it's such a cramped car, motor wise... Everything is squeezed in and compacted as much as possible. The radiator is basically one with the motor, not really but let's say so.

Removing a transmission on one of these can be a frustrating adventure. Heh I say adventure but it's more a trip down to the bowels of hell. Mostly every bolt you need to loosen has some sort of pipe or wiring harness blocking it and all of those pipes and or wiring harnesses are clipped in with pins so in order not to break them you have to be able to bend your fingers backwards.

Laughs Laughs

It's still a pretty little thing.

See what I mean?

It's so compact that the nose of the car almost pushes over the top of the motor, I mean you can barely see the air box of the vehicle.

Usually with vehicles like these you have either the top or bottom that is a pain to strip... never both.

If you struggle at the top the stuff that needs removing on the underside goes easy, and vica versa. Not with this one, you'll struggle at the top and then you'll head down to the underside and struggle some more. Oh and once you've unbolted every little thing you need to you will struggle to remove the loose parts from the engine bay...

What a marveling piece of engineering!

Hey at-least it's got a little tool tray above the nose.

😂

Now this is where the frustration starts...

Everything has these heat shields covering.. well everything. Since it's such a compact vehicle heat struggles to filter out and well some stuff don't like the heat so they have to cover them with heat shields to stop the worst of the heat.

The problem with this is that the heat shields are very soft and bendable which can be nice when you remove it, but upon rebuilding the vehicle you need to get those back into place and do so without misforming the heat shield plates. If you happen to misform them you'll have a hard time inserting all the little bolts holding them in place and there is no way of wedging or pulling them right while underneath the vehicle!

Earlier I mentioned that there are always a pipe or some wiring harness in the way.

Well there are bolts that needs removal where my hand is located BUT I can barely touch them with my fingers yet I'm somehow suppose to fit a spanner or a ratchet with a socket in there!

Like how Frenchman? How?? How you want me to do these things!

For those who have been following me and for those who has actually read the content.

This transmission is very similar to Ford's DCT250. Same dual clutch, same actuators and same TCM.

However nothing is interchangeable except for the actuators and the actual clutch forks. You can't use the TCM on a Ford or vica versa. It may bolt down and fit in the Ford but when you start the vehicle it will blow a fuse... Or well that's what happens when you fit the Ford one to the Renault. The reason for this is because the Ford has three speed sensors and the Renault has two so it doesn't really know where to push the power for the third speed sensor.

Okay enough with the Ford's.

So this doesn't look to bad does it?

Well I have already started removing some stuff from the underside, namely half of the sub-frame. Yeah in these cars you can split the sub-frame... What exactly might be the point of the when you have to remove the whole damn thing anyways.

Just look at how ugly it is. Yeah those blue spray marks... Those are fitted at the factory😅 I've seen them on all of the Renault's I work on.

I'm down to the last two bolts and she'll come right out..

Laughs no she wont, she'll struggle and complain and try to scrape her way back inside the car!

Nothing a tyre lever or two can't sort out, wedge wedge.

I don't think I mentioned what we needed to work on transmission related, but we needed to replace a clutch on this one. It seems like the clutch ratchet has broken thus it's pressing the pressure plate part of it so tightly against the clutch that it can't really do anything. This causes the transmission to slip indefinitely it might also cause damage to the actuators and your TCM so something as simple as that can really end up costing you thousands...

Most people just continue driving like that! Those are the jobs that are most fun to work on.. You replace so much that nothing can really go wrong with the repairs.

Lovely isn't it?

This is not a brand new clutch, it's a refurbished one... To be honest I can't remember if we have ever done a brand new clutch on these... They are just too damn expensive, costs more than 2 grand in USD... Although this is just as good as new for a nice price of 500 USD.

Major difference in price ey.

A lot of bolt loosening for a quick exchange of the clutch.. Can you believe.

It took me no longer than ten minutes to remove the old clutch and fit the new one. No more than ten minutes, yet it took me more than two hours to remove the transmission. so lets round that up to four hours and let's add another hour for shit talking. That's 5 hours for a actual ten minute job.

Hectic ey.

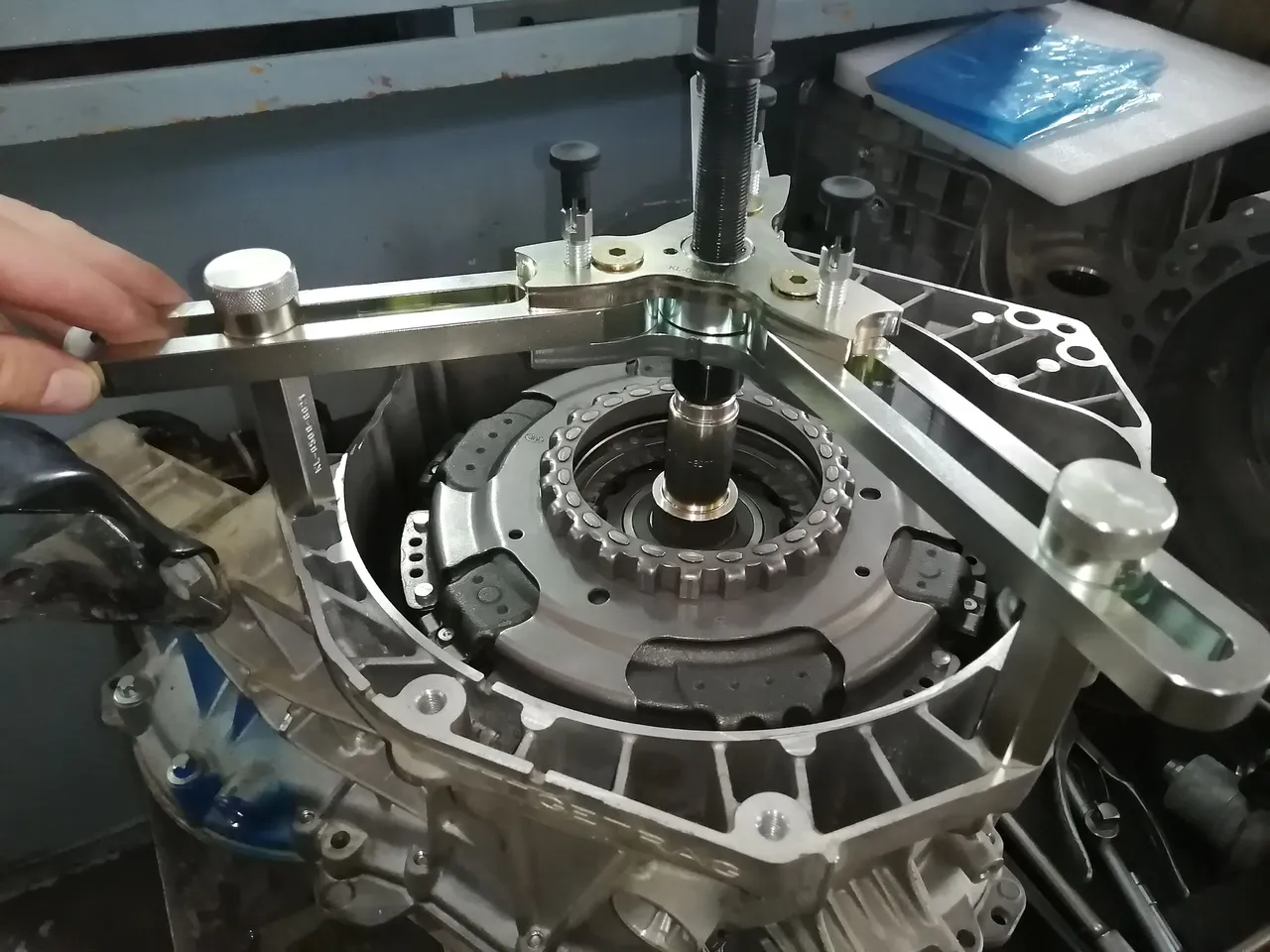

Now this is the right way of installing one of these clutches, most would now say but usually a clutch is bolted down on the fly-wheel of the vehicle... Nope not these..

I have to say that I've seen oaks hammering this clutch into place. They end up screwing up everything, mainly the big bearing right in the middle of it... And well when a bearing seizes up, it can be fatal and catastrophic. In theory it can rip your whole motor and transmission apart.

That would be a killer.

Another one done and dusted ready to go home.

Dated 30/01/2023

Connecting the people of #HIVE across South Africa. #hive