Ok, 3D printing Hive fans a few weeks ago I posted on my IKEA Lack enclosure and Copperhead heatbreak as a prelude to printing some ABS, well today is the day,

I'm not printing anything spectacular just the standard 3D printer overhang test sliced in Cura for a generic ABS, hot end 230C, and a bed temperature of 90C. the only thing I changed was the retraction down to 2.5mm because of the Copperhead all-metal heatbreak.

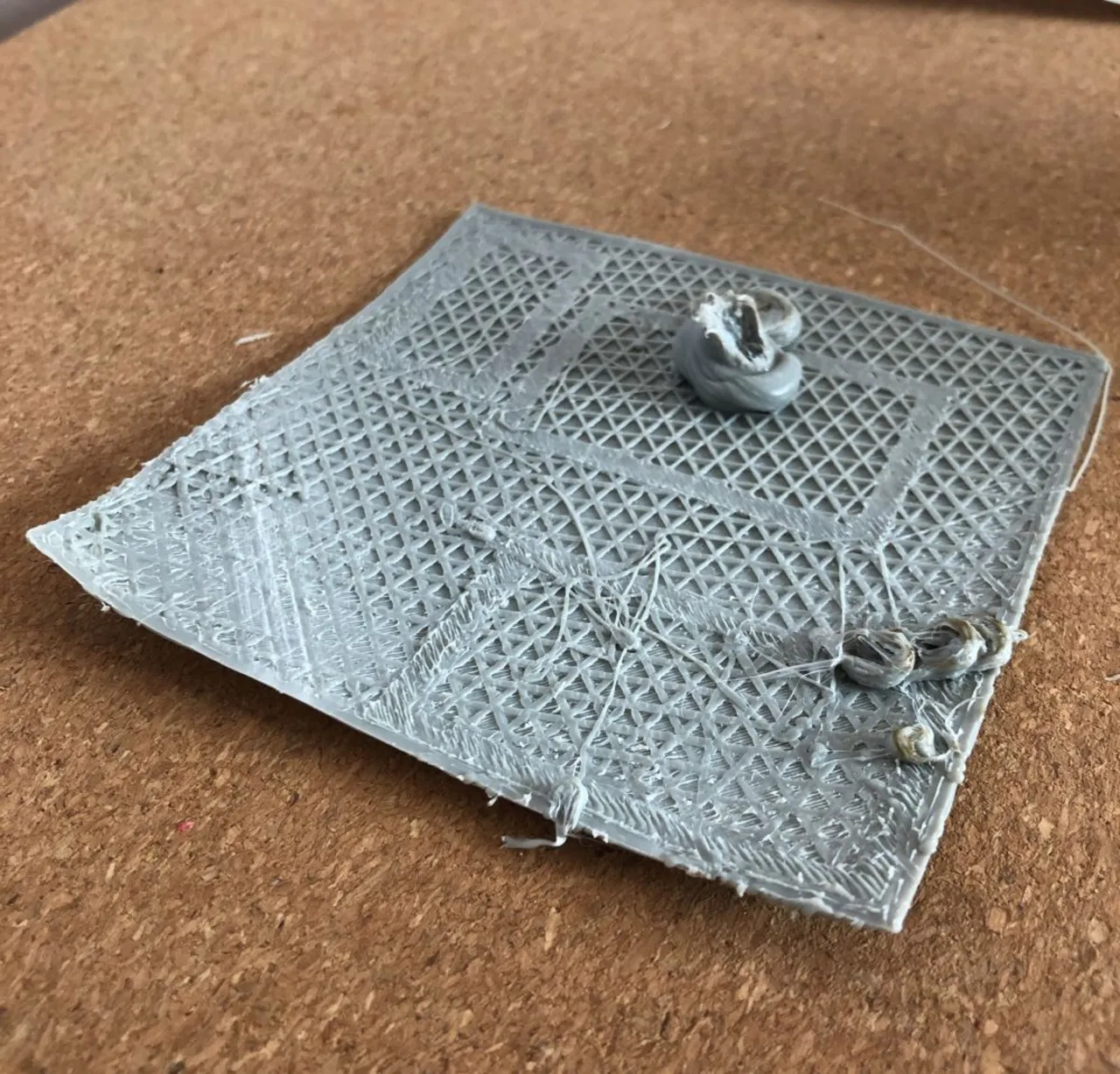

Well, the first try hasn't gone so well about 1mm into the print and it's all sliding :(.

Bed cleaned and off we go again. Still no joy much the same with same print settings, the print warping off the bed at about 1mm.

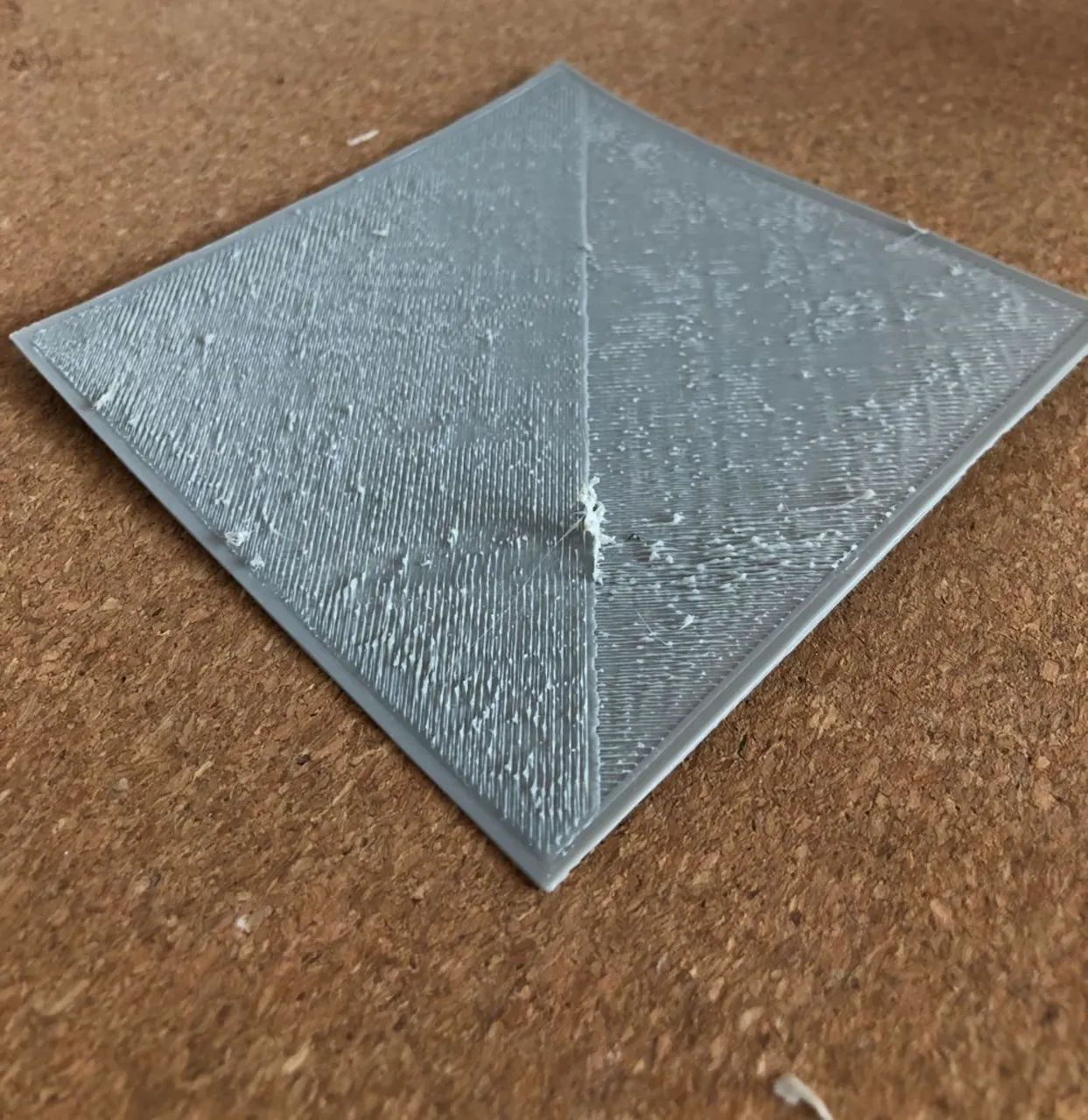

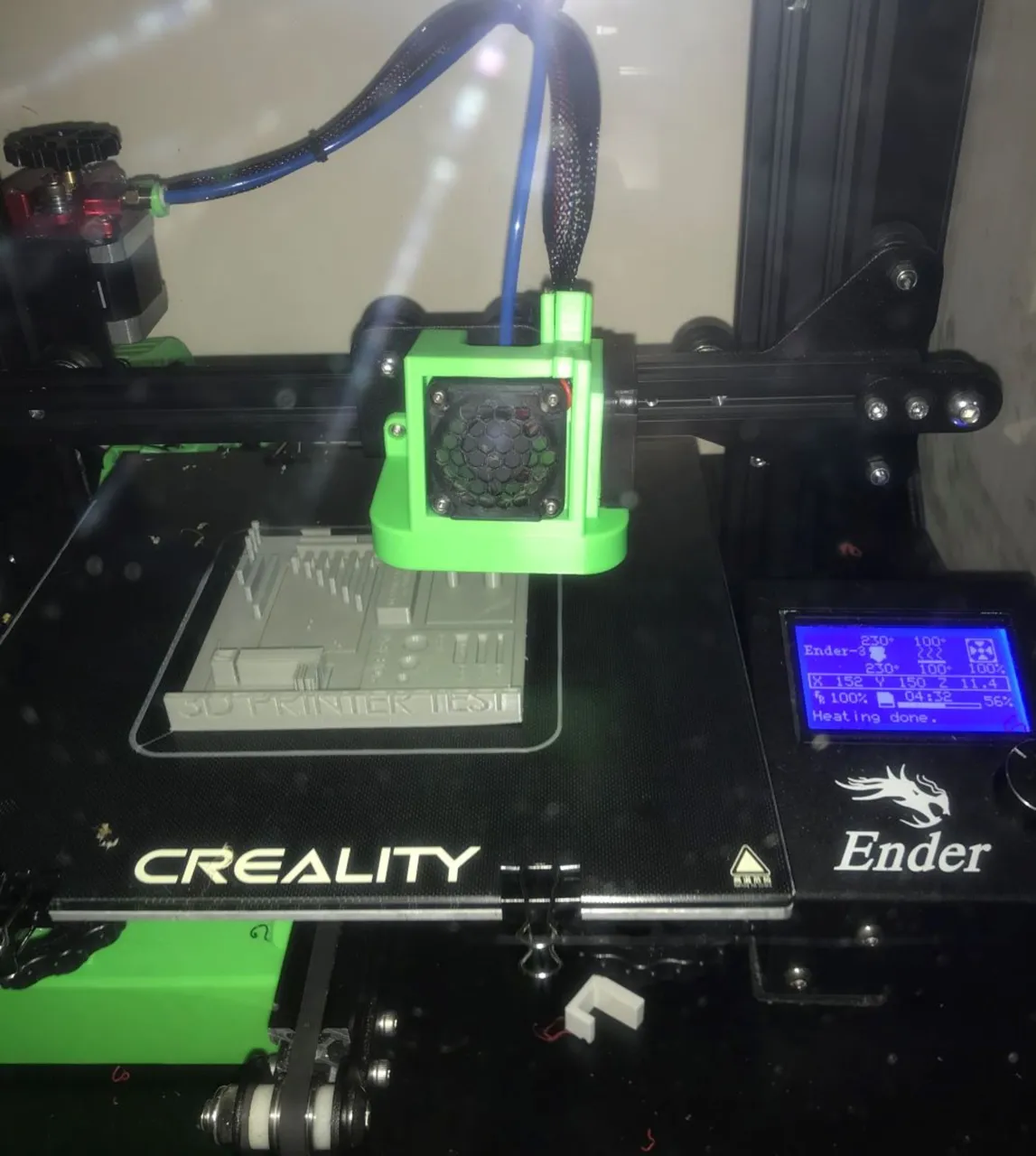

Time for a rethink and tweak the slicer settings a bit. The hotend seems OK and the extruder isn't skipping so just up the bed temperature to 100C and reslice the print. A bit more joy with these settings 4.5 hours in and it's still stuck with the print going well apart from a slight lift in one corner. I'm not going to risk opening the door though so let us see how this ends.

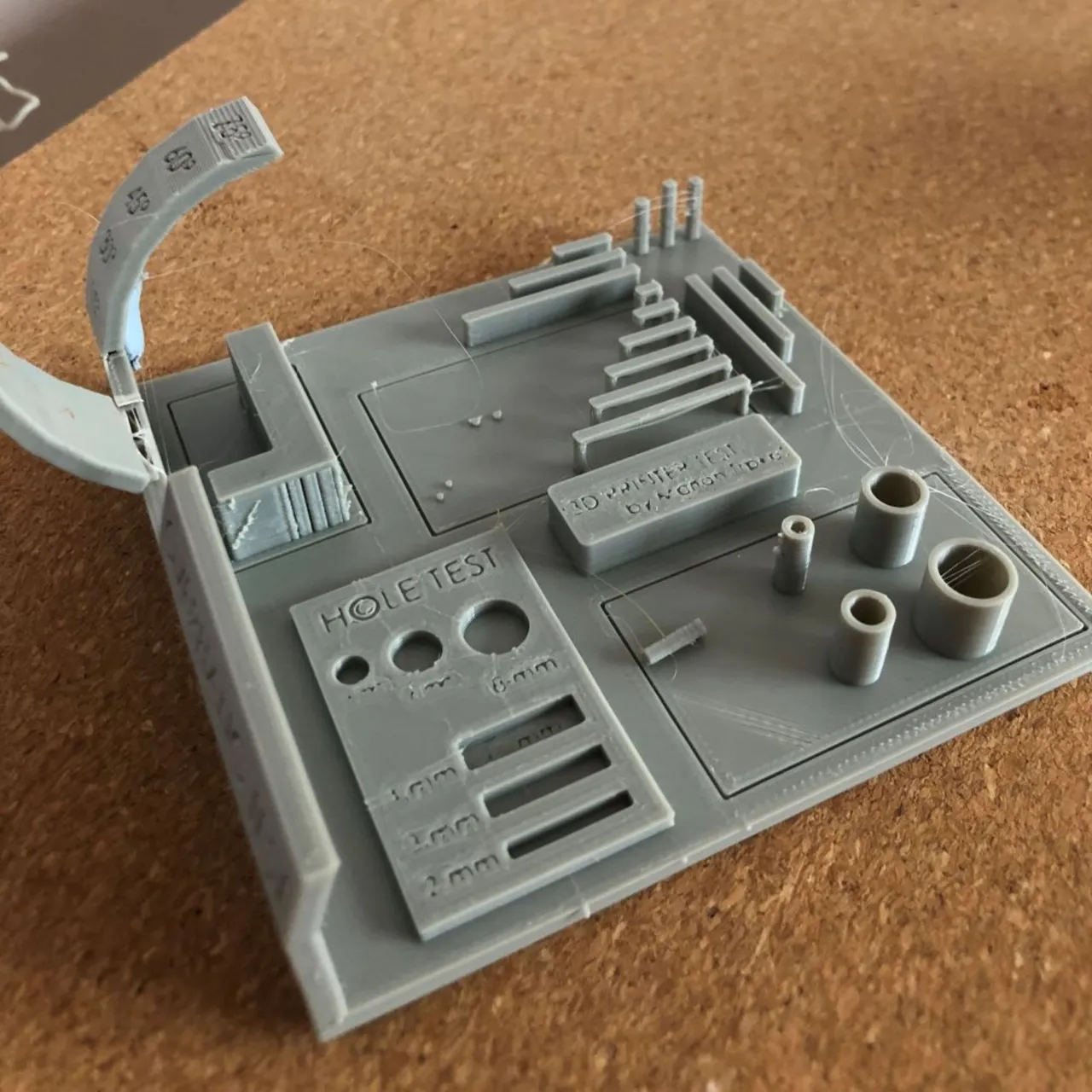

Ok, 7 hours and a couple of issues at least the print stayed on the bed this time. I'm not too concerned about the broken right overhang tower I know what caused that. I think it's time to see how some real-world prints go after a couple of tweaks to the slicer program.

Ok Hive 3D print fans I have learnt a few things with the test print and slicer tweaks. On a positive note, the ABS print is really tough which is what I was after and the enclosure did stop the layers from splitting apart by keeping the temperature up. the final settings were 230C on the hotend and 110C on the bed temperature, I slowed the feed to 50mm/s as well. Finally printing ABS does whiff a bit not too bad with the enclosure but a really hot plastic smell when you open the door.