Tareq Ajalyakin | Unsplash

It is clear that the Asian continent has recently made great progress in the manufacture of electric vehicles. What is more, we can say with certainty that development cycles are being considerably reduced, although this could be interpreted as something positive, but it is not entirely so.

Let's imagine that production process times are greatly reduced, facilitated by new technology and innovation. This in turn would lead to a concentration in costs and time. In other words, a significant demand for orders that would accumulate and generate backlogs, coupled with the need to invest even more in order to continue competing in the sector, would be something to worry about.

Everything indicates that the Chinese automotive sector has become a market that has evolved dramatically compared to competitors in the Western region. If we compare the launching of models between the Western and Chinese sectors, we would be really shocked by such a difference. We are talking about the fact that while Western manufacturers take more than four years to bring concepts to market, the Chinese sector requires only 18 months for the models to finally be released.

Talking about electric vehicles would be meaningless without mentioning batteries, which are a form of energy that is being adopted on a large scale around the world, and which represent an alternative to fossil fuels. Of course, the sales of these vehicles could be influenced by the quality and quality of certain components, something that could determine a boost in sales of these vehicles, or on the other hand, fail to achieve them.

It is clear that the evolution of the market has been growing consecutively, which leads us to think that making a sort of prediction about the future of the market could be in vain. This leads us to think that battery manufacturers should somehow consider giving more flexibility to software than to physical components, so that there are no excessive costs in an unpredictable context.

Breathe is a solution that offers a series of tools to manufacturers to get the most out of batteries. Everything happens at the software level, with the particularity of improving battery development processes, through up to four products: Design, Model, Map and Charge.

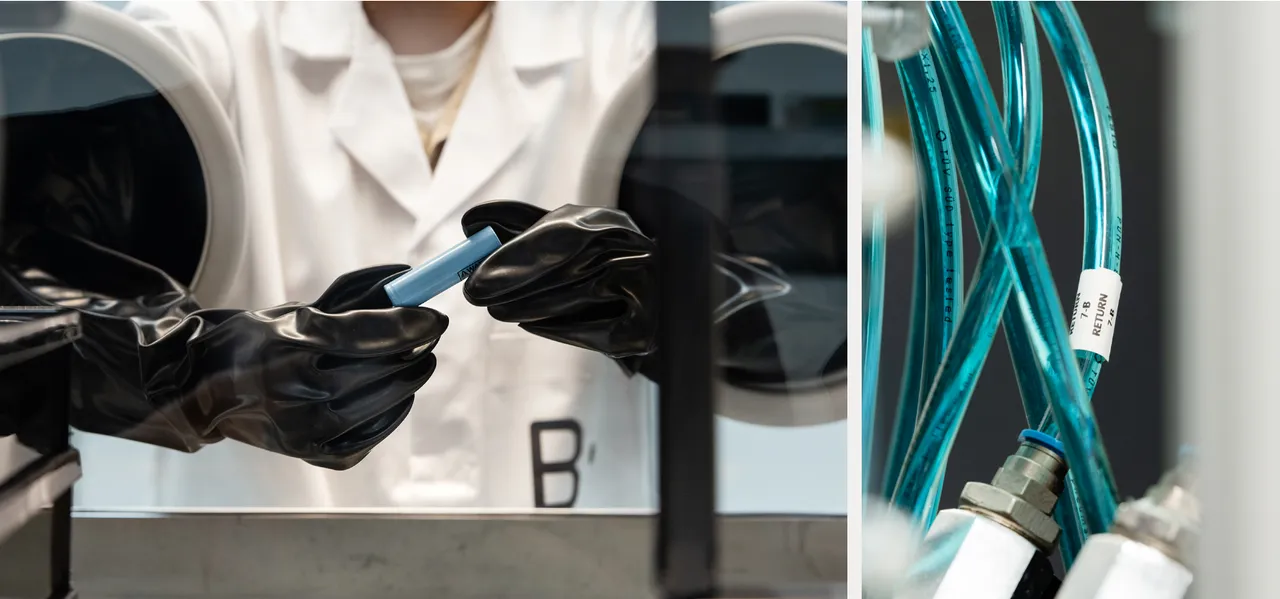

Image from Breathe official site

Batteries often experience erosion in the way they are charged and discharged. If we consider this as a fundamental part of the service life, it is to prioritize the optimization of each charging strategy, positively affecting the longevity of the battery. In addition, it must be considered that at the end of the production process, the battery cells are not always identical. This results in problems such as even higher than normal heat generation during fast charging.

One of the companies in automotive sectors that have included Breathe software is Volvo. The code, which has been installed in the upcoming ES90 sedan, has enabled a considerable reduction in time, towards 20 minutes, for charges of between 10% and 80%.

The startup has also received interest from other companies seeking to maximize the efficiency of batteries, not only limited to electric vehicles, but also to the electronics itself. In this way, it is possible to make an analysis of where to direct development resources, designing and predicting the future performance of these batteries. If new chemistries come to market and represent much cheaper costs, while maintaining or exceeding their useful life, one might choose to think about sacrificing some of that longevity for the sake of faster charging.

Breathe has a laboratory in London where it can perform all kinds of tests on the batteries its customers are looking to use. After these tests, the customer can receive a model called a “Breathe Model”, which will be used to simulate future performance. The laboratory is also suitable for the cells to provide more data, with the intention that the customer receives the Map product. This product aims to complement real data with simulation data. Finally, if we talk about the Design product, it is expected to be launched in the coming months, and will seek the acceleration of the batteries by the software, based on a set of tools that allow their optimization.

Financially speaking, Breathe has managed to acquire after a series B financing, the sum of $21 million dollars. This round was led by Kinnevik Online AB, with participation from firms such as Lowercarbon Capital and Volvo Cars Tech Fund. These funds will be used to boost the software push with respect to the early stages of the battery production process. Considering that important companies could be direct clients of the startup, we could see in the medium term electric vehicles that have gained in optimization and autonomy.

- Main image edited in Canva (contains an image owned by Breathe).

- Information has been consulted in: techcrunch.com.

- Translated to English with DeepL.