This machine is greatly appreciated, not only it drops the seeds at a set rate but it also pushes them into the ground. Running this attachment through the tilled fields should place the Rye/Oats/Orchard Grass/Clover seeds into the ground and wait for a good rain to germinate them. I asked the farmer that dropped off the machine how you can how if it will rain good enough, he said there's no way to know for sure and a lot of it is just luck. So we will take a chance and put down the seed and hope we get normal amounts of rain, the South tends pretty high levels so as long as it plays out as it has in the past we should be good.

I rented this machine, as we only would use it once every 5 years or so. Seeding the field we hope many of the crops come back each year by dropping their own seeds or some based on their perennial nature.

The machine was dropped off by a local USDA office operating in the area, I learned about this by speaking with some locals about how they seed their fields. Renting this they charge the acre used, in the end we will seed around 25 acres.

We hooked up the machine was the guy that dropped it off showed us how to use it.

This machine holds the seed and drops it through those tubes based on a setting. The drop rate and depth of planting can be changed.

Each wheel that pushes the seed into the ground has a drop tube all the seeds fall through, we need to make sure they do not clog up every so often.

The Haybuster 107C suited our needs and we were thankful we could rent one near by.

It attached right to the back of the tractor hitch and we controlled dropping the wheels by hydraulics.

Many stickers showing proper using and warnings about the farm machine.

The seed bins were separated by three partitions, so you can have a grass bin, a clover bin and a grain bin. Each has its own settings for drop rate and depth.

We stocked up each bin with many 50 pound bags of seed.

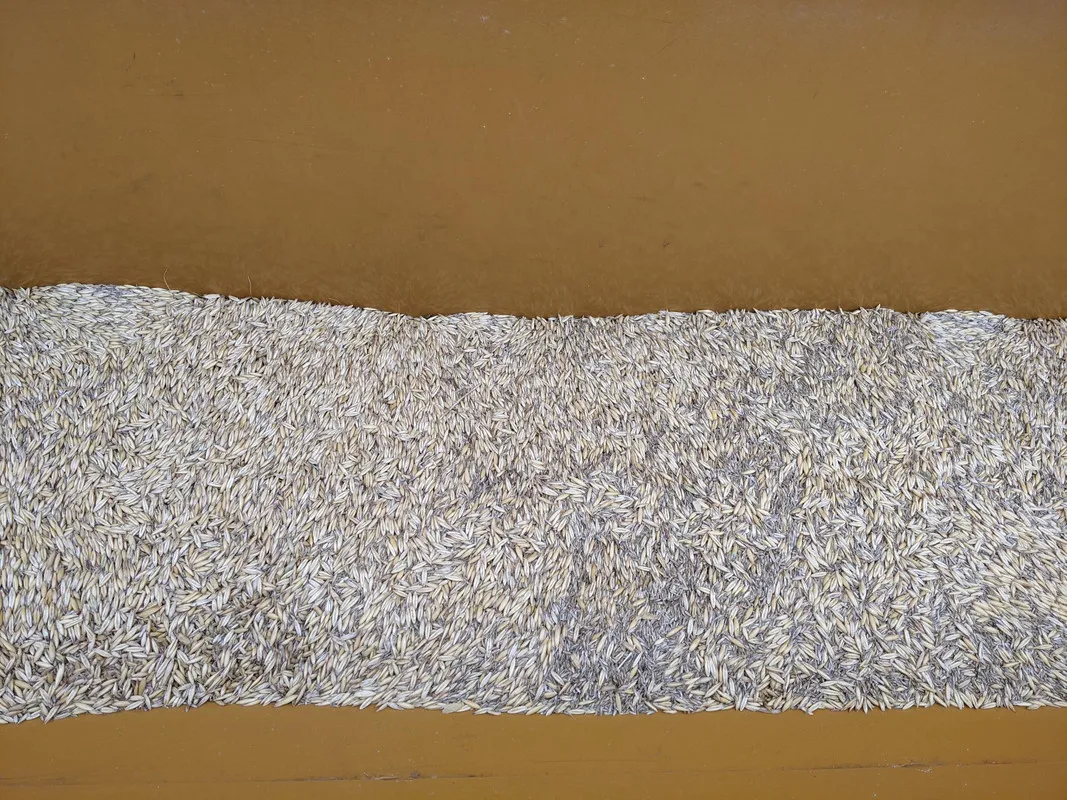

The tubes can be seen above with the grains all around. When we filled it up the first time we forgot to close the doors and some fell out before we could close them in time.

These wheels use the weight of the machine and hydraulics to drive the seed at the right depth.. around 1 inch but it can vary on the seed used.

Clover can be seen above, it has a nitro coat on it. This coating keeps the seeds from germinating if we get small amounts of rain. But will activate when I get enough to germinate them. Interesting idea so we shall see if we get no rain, and then nothing but clover comes up.. haha

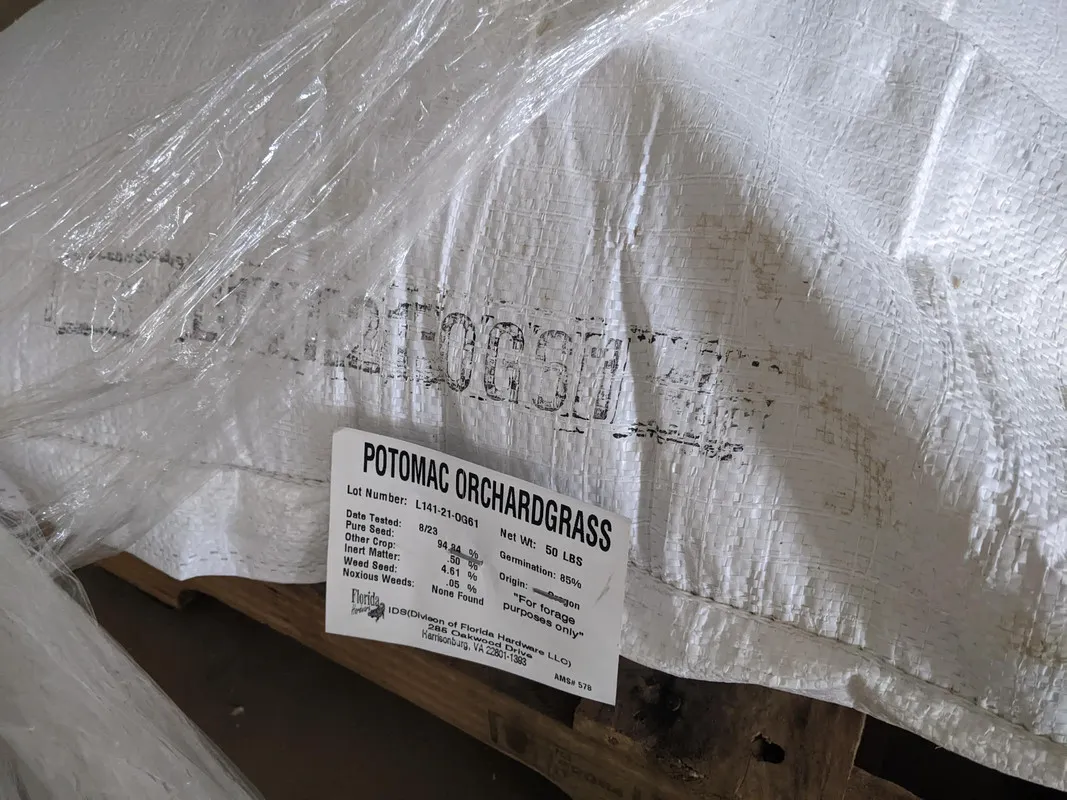

We are mixing some Orchard grass into the fields as well. That way we have more than just Rye growing as a dominant grass.

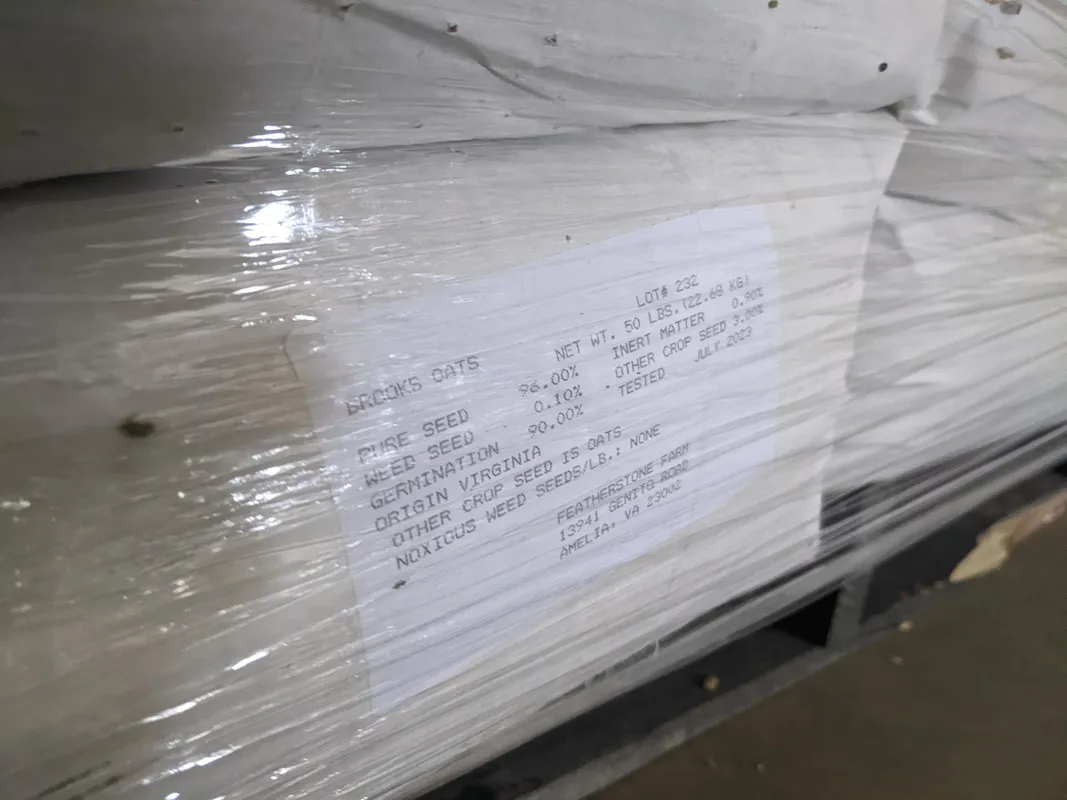

We got lots of oats, about twice the amount needed. We wanted barley, but the bags the supplier had mites in it so they did not end up selling it to us. So instead we got double the amount of oats.. We can save this for animal feed as well, or seed by hand without the machine for the remaining oats.

Not sure if the Oregon grown and the Potomac is the same, but more grass seed bags.. each are around 50 pounds.

The oats we have left over we will need to keep them safe from rodents.

Taking the seed drill into one of the smaller fields on the property.

We can see how the lines are made, this is where the seed drill has pressed in seeds into the ground.

Will need to watch out for birds trying to get at all those seeds.

My foreman driving the tractor, we can see the wheels are dropped down and putting the seeds into the ground.

After we are all done with it we have to clean it out good. We scoop out what we can and then blow the rest out.

A leaf blower works well, you have to get up on top of the machine to get the bins cleaned.

We cleaned it up real good and it was picked up the next day. Now we just need to hope for rain.

Cleaning out the machine with the leaf blower sent all kinds of seed up in the air and all around where the machine was. So we spent a few minutes just disbursing the best we could.