I've had a little extra time available lately and have made great use of it. I've been hiking more, working on some writing and reading, pushed my body a little harder through longer runs, more weights and some flexibility training and have spent more time shooting. I'm up at 05:30 and don't go to bed until 11:30-01:00 and have managed to get a lot done in the hours between. I'm ok with working hard, it's just what I do.

The additional shooting has been fun not work, I enjoy it because I get to spend time in places like you see above, but it also means I've been going through more ammunition which, of course, brings more work because I make my own. It's not something I leave until I have none left of course, only a fool would do that; I keep a minimum level of rounds for each of the calibres I own: Rifles, hand guns and shotguns and that means I'm often in my workshop making ammunition and that's where I was yesterday.

I generally do my reloading in stages as there's a few to get from fired cases to new ammunition and yesterday I was resizing. I took a few shots and put together this short post to show the world, or the handful of people who will actually open this post at least.

Above, in my hand, are once-fired cases which I've de-primed then cleaned in my wet-tumbler. After drying them (in a food dehumidifier) they're ready to be resized. This is done by running them up into a die which squeezes the cases back into their original shape and tolerances. When the gunpowder explodes on firing the cases blow out very slightly and the case also lengthens so they need to be returned to factory tolerances before being reloaded again and fired once more - They will jam up the firearm if not resized.

You can see the resizing die in my hand and some cases ready to go into it along with a little container of lubrication which helps the process along. Very small tolerances are involved and the lubricant is there to ensure smooth operation and also to protect the (expensive) die from damage. Only a very small amount is used though, too much and the case may be dented by the pressure created when it runs up into the die. Like I said, I'm working with very small tolerances.

Press and die

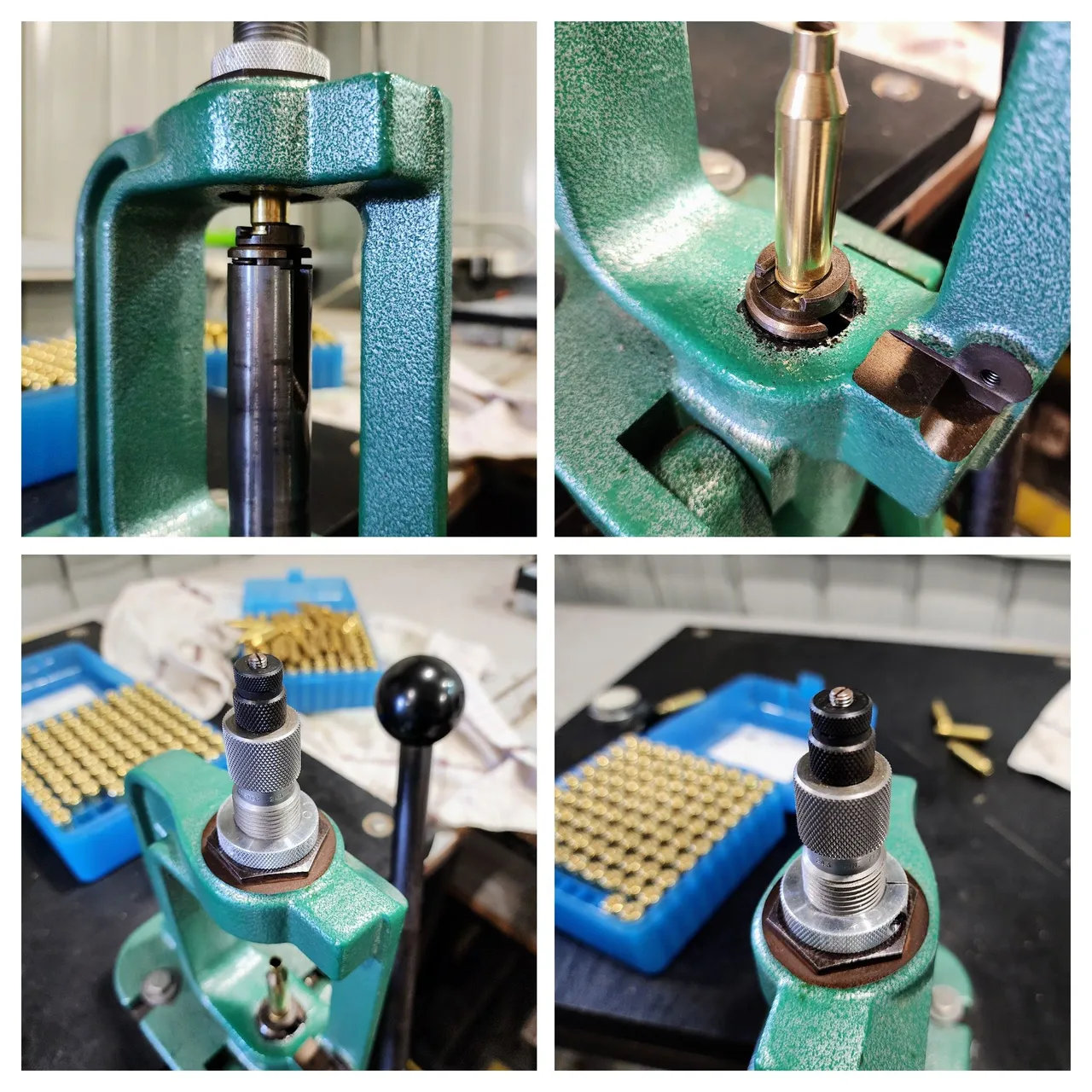

Below you can see the press into which the die is screwed. The die is specific to a particular calibre, in this case .243, and must be set to the size of the case so it doesn't damage it when it is cycled, using the black lever you can see.

The ram, has a case holder slipped into it (Image below, top right) which is what retains the case and when the lever is operated the ram (image below, top left) rises pushing the case into the die. Some force is required but the lubrication, as mentioned above, helps. The lever is worked again in reverse which lowers the resized case out of the die.

Once resized, I wipe over the case to remove any residual lubrication and drop it back into the box ready for the next stage.

The next stage is re-priming the case.

Chamfer and debur

You can see a case without a primer and with (below image, top left). The primer is simply a means to ignite the gunpowder in the case (once the trigger is pulled and the firing pin strikes it). It explodes into the case/gunpowder through the flash hole you can also see in the case on the left in my hand and from there the gunpowder ignites. It's a simple process really.

But before the case is re-primed the neck needs to be chamfered and deburred and you can see the tool I use to do that below (top and bottom right images). The chamfer is put on the inside of the case neck to help one seat the actual projectile later on, and the deburr happens on the outside of the case neck just to remove any burrs or imperfections that may occur from the resize and trim process.

Trimming

As I said earlier, firing a round can stretch the case neck, as can the resizing process, and sometimes the case needs to be trimmed. I actually forgot to take photos of this because I hate the process to be honest. I can do a post on case trimming at some later point though. Basically, the case is measured and if out of length-tolerance is trimmed on a tool designed for that purpose. This also causes the burrs that need to be removed.

Also below you can see the wax lubricant I use. In the container I've put a little square patch of cloth which is what I run my finger on to get some lubricant; it's just a light swipe which I rub between thumb and forefinger and then wipe around the case neck and part of the body to spread some lubricant. When done, one can't even see the lubricant with the naked eye, other than a slight glossy film.

So that's about it, a very basic rundown of the process of resizing a case ready for reloading. It's not rocket science, but with all the very small tolerances involved one needs to know what one is doing. Fucking this up is costly financially through wasted components and possible injury or death if the process is not done right. Making mistakes in reloading ammunition will bite a shooter at the very worst time, when the ammunition is fired, and can have a devastating effect.

I resized almost 500 cases yesterday which took a long time and over the next week or so I'll re-prime them and begin the actual reloading process which is where the precise amount of gunpowder is measured in and the projectile is seated and pressed into place.

If you have any questions, I'll be happy to answer them or just leave a comment below if you like.

Design and create your ideal life, don't live it by default; tomorrow isn't promised so be humble and kind - galenkp

[All original and proudly AI free.]

Any images in this post are my own.