Well I'm going to have to modify a jig here in a minute.

Good thing The jig is already paid for itself.

So little bit of grinding action is going to start happening and I get to leave a bunch of time in the hands of this project.

Next thing you know I'm going to be highly experienced in Dremel machining.

So this is a great project to get more practice.

And a bunch of bits for me to really get into places and if you'll notice the shanks on these are actually a bit longer than the other bits that I have.

So this project is definitely going to be looking like it's going to really work out well.

Very excited indeed very excited.

And I think I have a couple extra tricks up my sleeve.

And of course my handy little helper is absolutely going crazy.

Of course super puppy is very interested in this new project and especially all the new smells.

So definitely going to be a wild time here coming up.

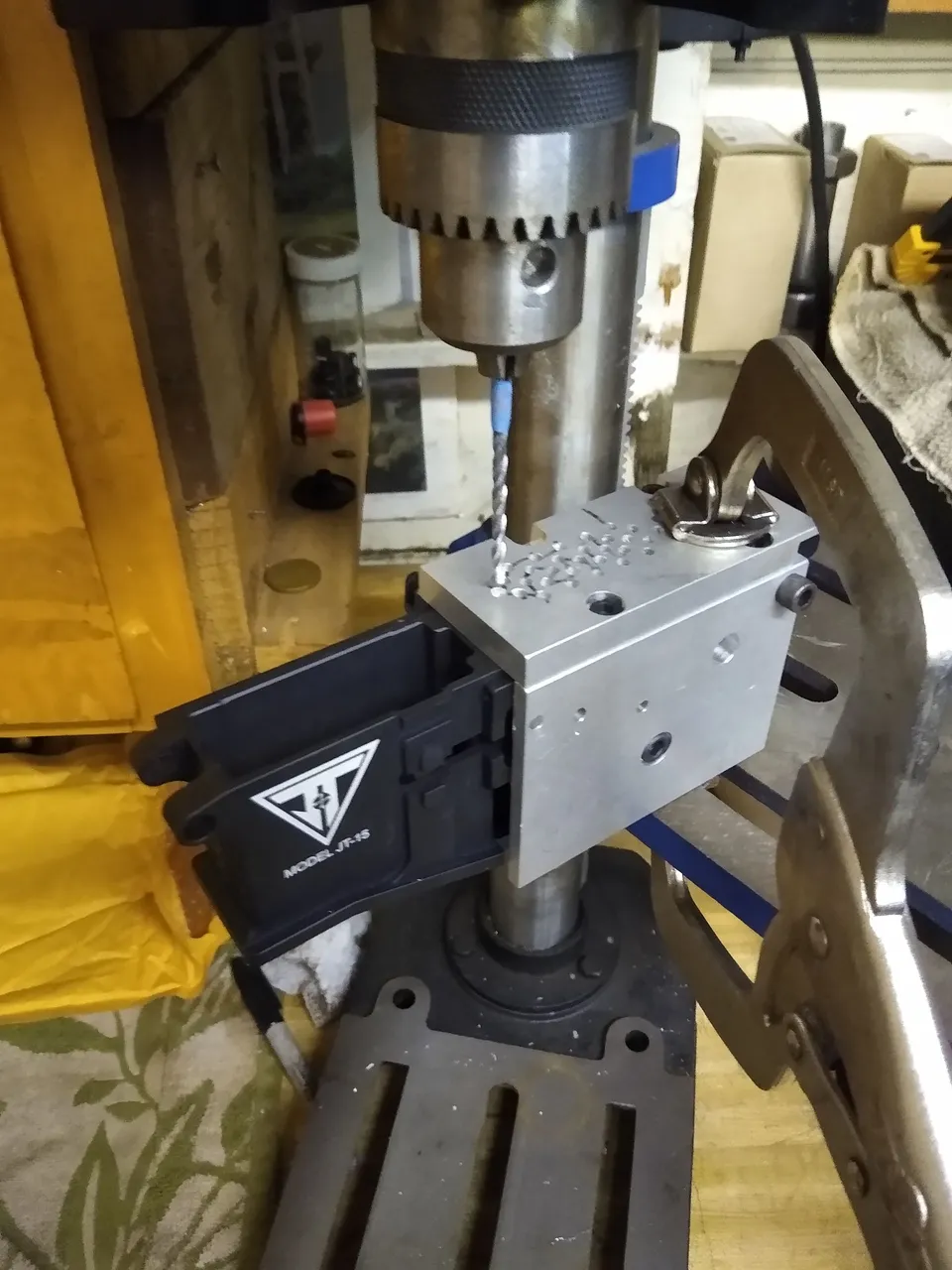

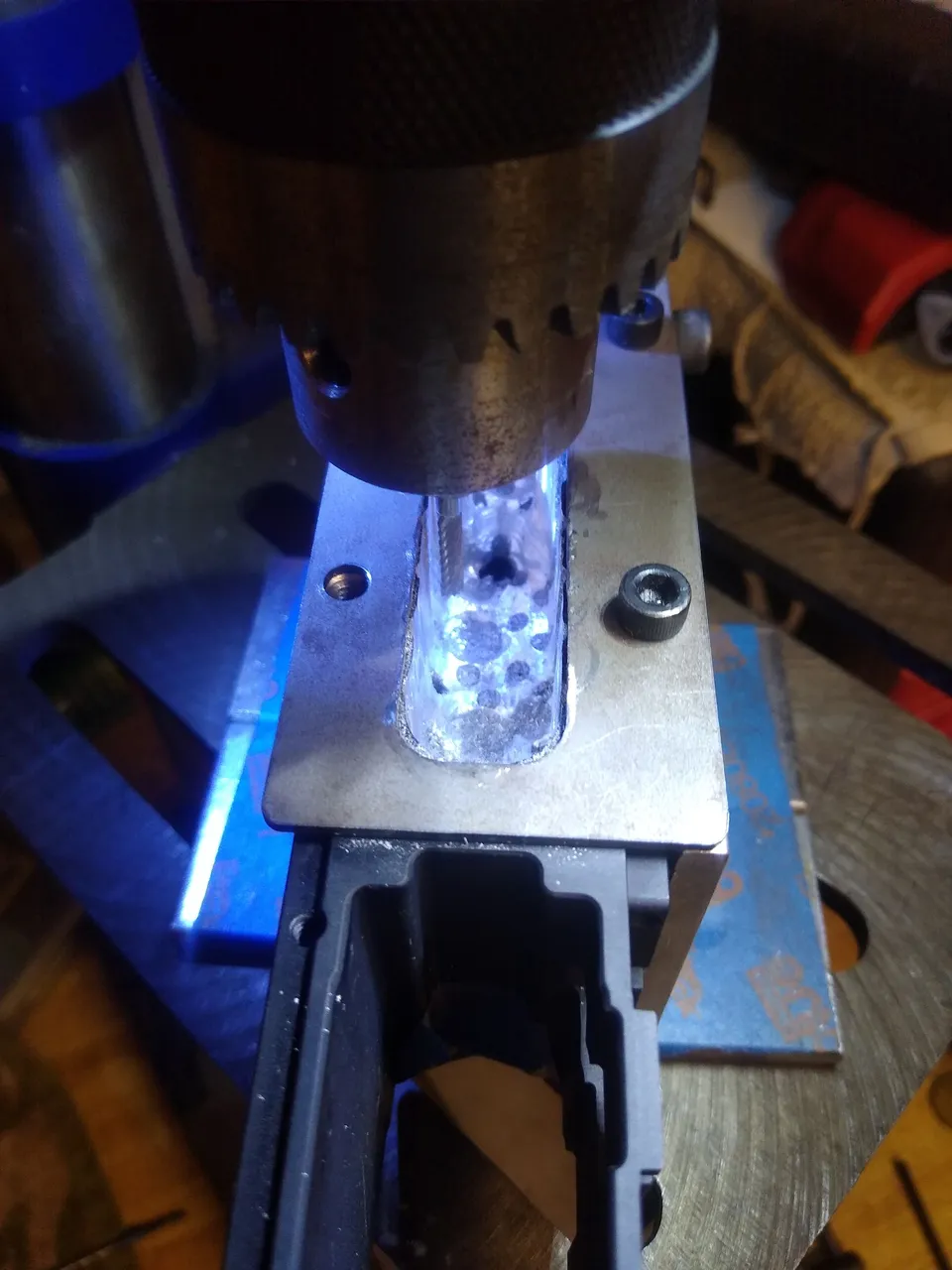

Depth setting... Nifty...

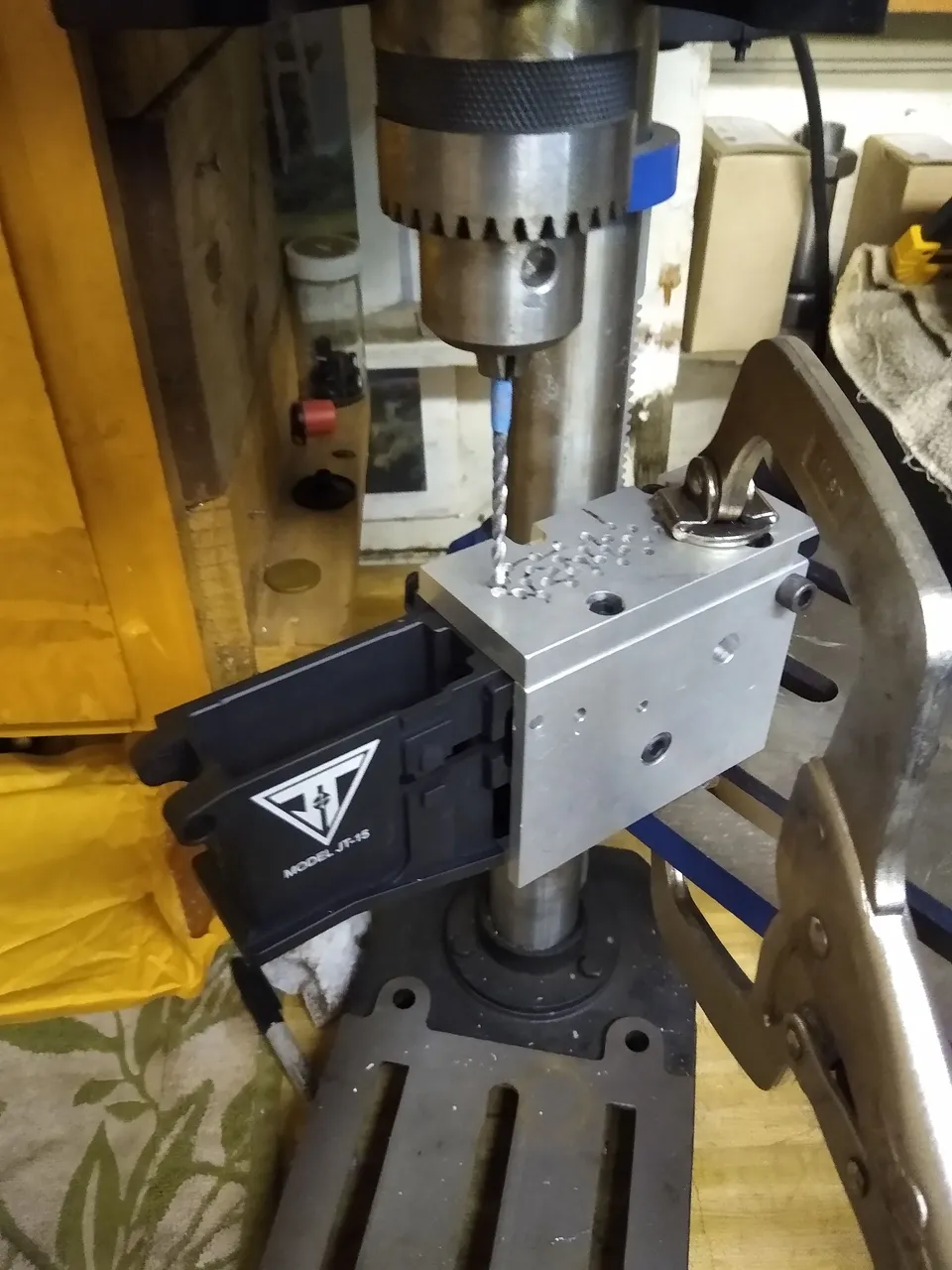

It's coming along!!!

More mass material being removed.

Each one of these drill bits definitely takes out a massive amount of material.

And now we are looking at some pretty phenomenal amounts of material that is already been removed and making further work extremely easier..

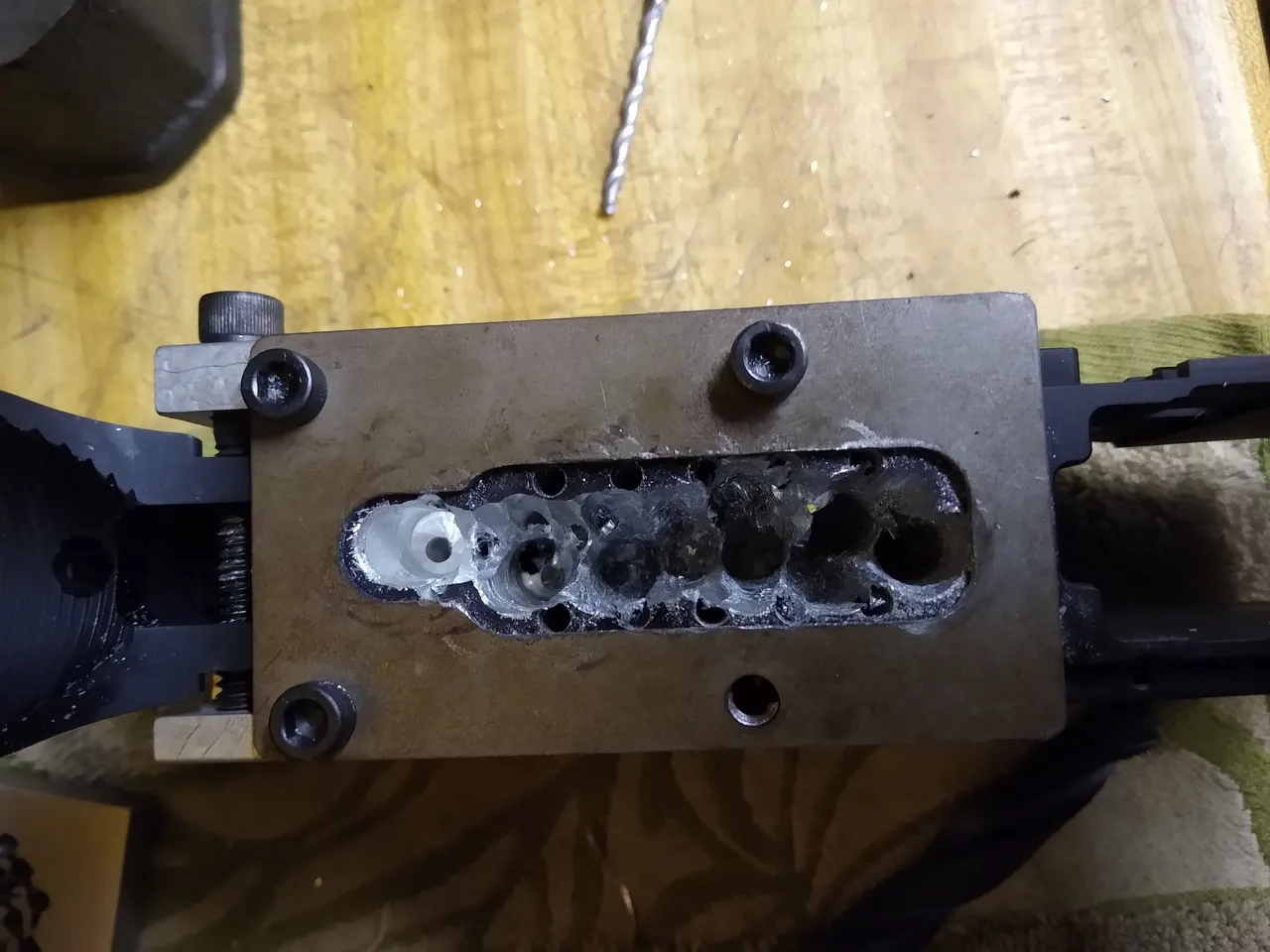

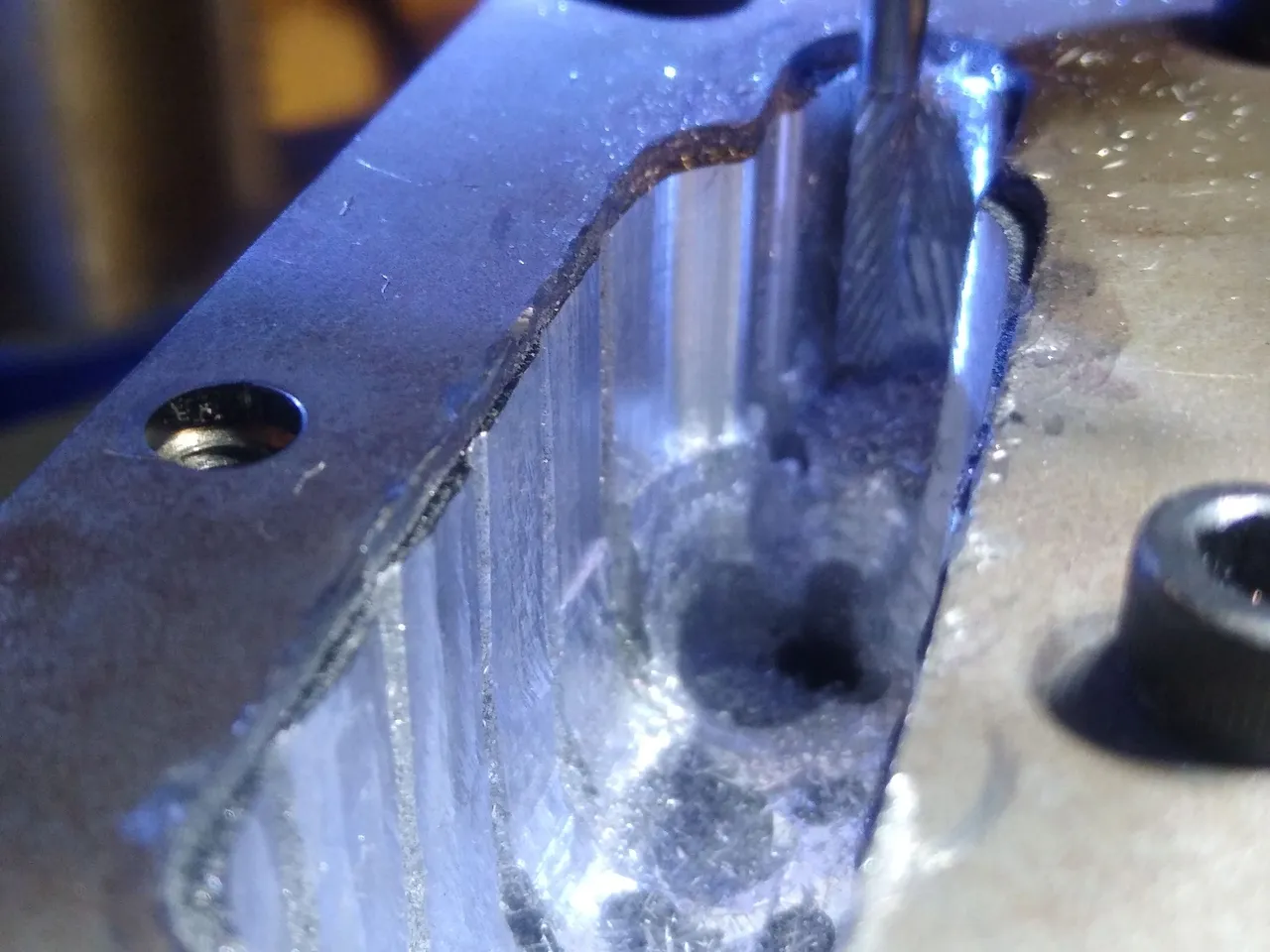

Switching out die grinder bits. We are starting to work on opening things up.

And these die grinder bits definitely help to remove material and the diameter and extra teeth definitely help me get to where I need to get going.

This is definitely looking pretty rough but you sometimes have to make a mess too get things cleaned up.

And it is actually opening up pretty well....

Hand machining is definitely pretty crazy and I'm excited to see this project work itself out.

And pretty soon I will get things set up to start

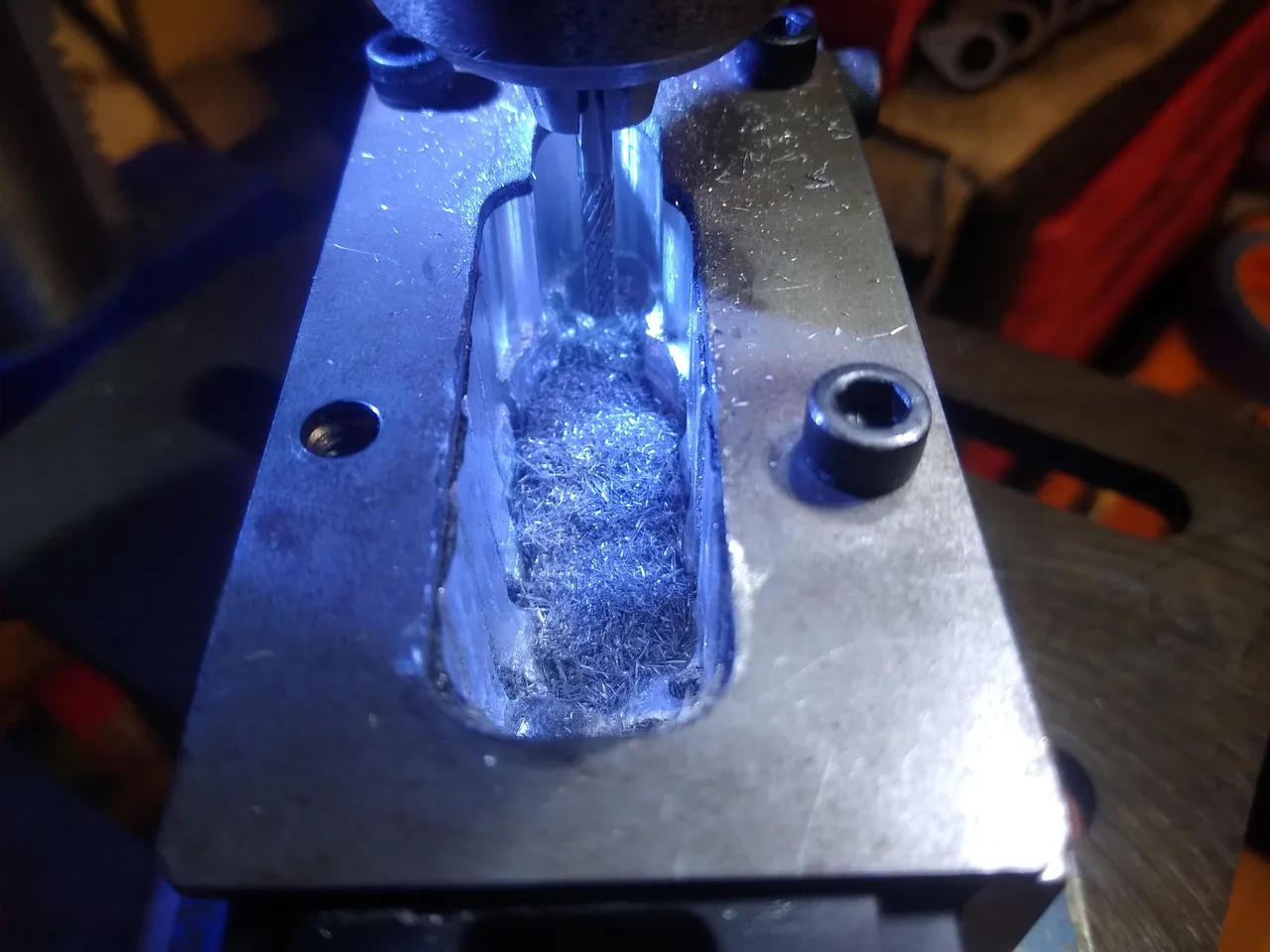

It's opening up!!! And getting closer.

It's coming together!!!!

)

And now....

On to decking the floor plate then the shoulder I need to remove...

Then a couple holes and this is finished..

And onwards to the next one.

Notes.

Juggernaut tactical.

As a business? This is the worst quality lower I've come across.

Let's start.

The paint.

Uneven blemishes and coverage.

Finish is lacking all sorts of surface defects.

Machining.

Lines don't match up.

Radiuses are not there. In alot of places they just machined out the least amount of material they could.

Parts.

Oh wow. Hang on. They forgot pins tensioner screws.and of course don't know what they list on the websight.

Which is the mag release and the ambidextrous bolt release.

So let's look at this...

Yep see that gap.

So either the ambidextrous bolt release button is out of spec for clearance. Or.... The lower is.

This is going to take extra parts machining and such to correct. So... Definitely don't think this is a great idea. It's going to be a nightmare.

Contacting the company? Poor idea. Miserable customer service and support.

Looking into the company? Huge negative reviews. Cheesy slick website and dumping poor quality products.

Out of the entire market? But from a manufacturer that supports the product. I am definitely glad that this entire project was funded by my generous friends. Thank you very much for getting to see different toys.

Definitely not going to be buying any further products and I will continue exploring the different fun machining projects.

Next up I think I'm going to run a bunch of dimensions and start working on a new chassis system for a friend's rimfire rifle project.

I think it's nap time thank you guys very much and today is my day off from projects!