The past weekend was a long and exhausting one for me. What started as a simple visit to the farm with my sister turned into a three days full labor.

Here's the full gist

On Friday, I went to the farm with my sister for inspection. The plan was just to check on the cassava we planted months ago, see how mature it had become, and determine when to harvest.

When we go to the farm, we noticed something unusual. Some of the cassava plants had been uprooted. At first we thought maybe it was from a previous harvest. But after checking more areas of the farm,we saw clear signs that people had been coming in to steal the cassava plants and some vegetables.

Since the cassava was already due for harvesting, we decided to begin harvesting immediately to avoid loosing more of it to thieves. The two of us got to work. Harvesting cassava is not easy, especially when it's a full plot of land and there was no machines to assist. We had to bend, dig, pull, carry and repeat the process over and over again. It was a stressful activity considering the fact that the soil was thick and dry in some parts, which made harvesting even harder. It took us hours to complete the harvest.

We didn't stop until the sun started going down. By the end of the day, we had filled four large rice bags with cassava.

The next day, Saturday, we began the process of turning the cassava into garri. This process was long long and demanding. The first step was peeling all the cassava tubers.

Each of the four bags had to be emptied and sorted for peeling. We removed the brown outer skin to reveal the white flesh inside, as soon as one bag was done, another one was opened. The peeling continued untill all four bags were peeled. When we finished, there were piles of brown skin around us.

Fun fact The cassava peels can be fed to goats.

After peeling, the next step was washing. We washed the peeled cassava thoroughly to remove any dirt, sand, and kin remains.

It took multiple rounds of washing to get everything clean. Once we were done washing, we packed them into sacks and took it to the local grinding machine, where it was crushed into a fine pulp. This stage was much faster because the machine did most of the work, but we still had to carry the heavy bags and supervise the grinding.

After grinding, the cassava pulp was packed tightly into strong sacks and taken to another machine that would press and squeeze out the water. This step is very important in garri production because if the pulp is not properly drained, the garri will not fry well and may go bad quickly. We left the bags in the press and returned home in the evening.

On Sunday, we returned to collect the processed cassava which was now in a semi-dry state, almost ready for frying. Almost, because we had to sieve the processed cassava to remove fiber and lumps.

|  |

|---|

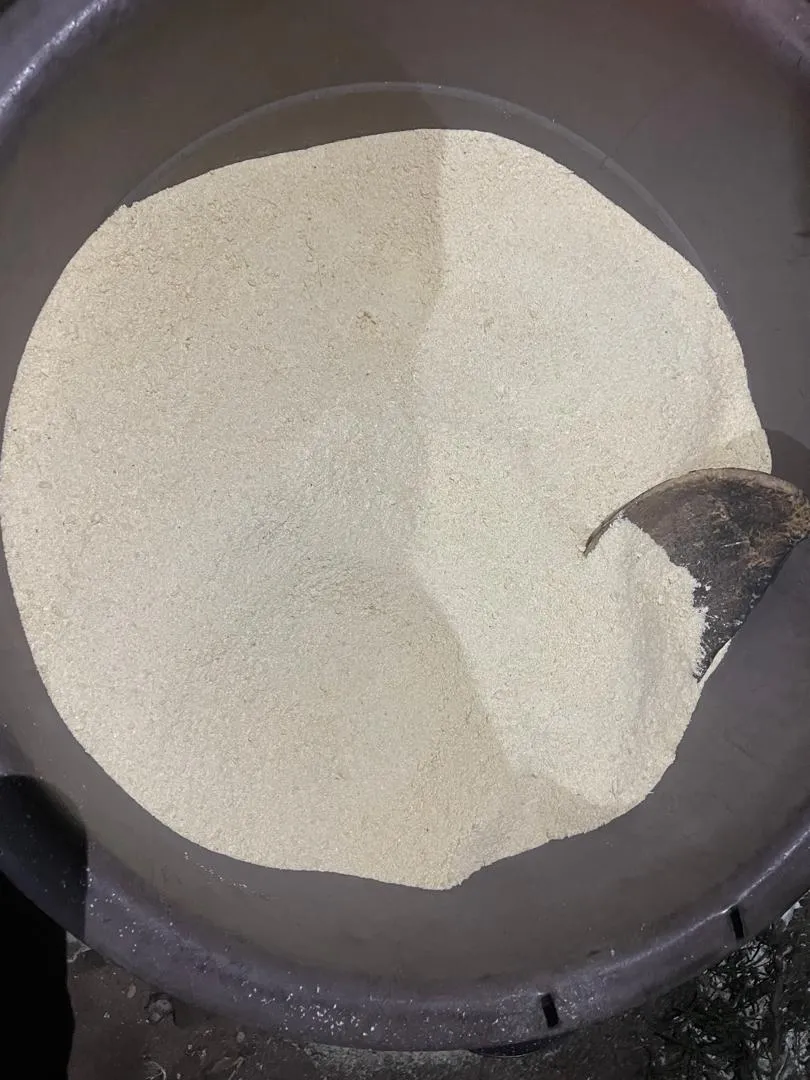

My nieces and nephew helped out. We poured the cassava into large sieving boards and started sieving. the sieved powder had to be smooth and fine, which is what would eventually be turned into garri.

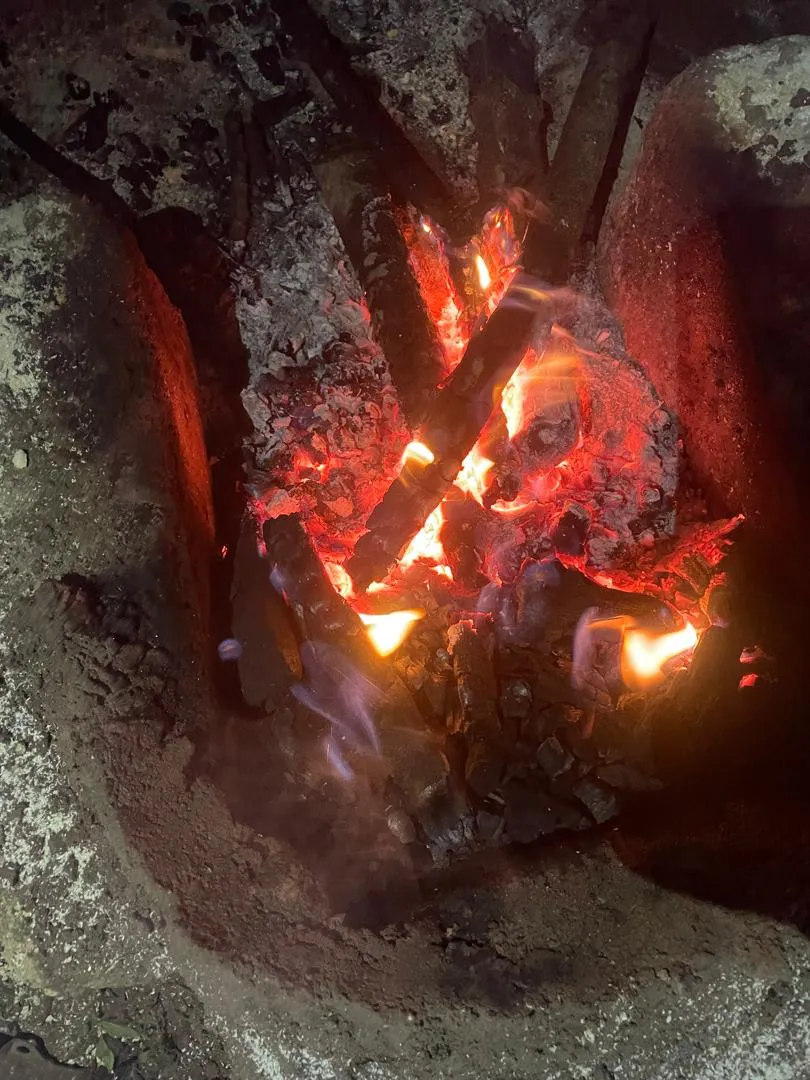

My sister set up a fire place, and started the frying while I continued sieving and helping to turn the garri in batches. We had to fry in portions because of the quantity.

This went on for several hours. The smoke from the firewood was harsh on our eyes, the heat from the fire was intense, and our arms ached from constantly stirring the garri.

We worked from morning till evening. By the end of the day, we had processed all the cassava into fresh garri. It was satisfying to see the result of our hard work, bags of neatly fried, clean garri. We let it cool and then packed it into containers.