Things are really getting intense with the technological advancements that are being made. What was once science fiction is starting to be more realistic with each passing year.

More than a decade ago, researchers started to get serious about programmable material. Also known as smart material, this could radically change the way we put together different products.

Presently, we live in a 3D world. To enter the 4th dimension, we need to factor in the time element. Programmable materials are the entry into this.

How would all this work?

Let us consider how things are today. We when order a piece of furniture, a table say, it comes in a flat box disassembled. Upon arrival, we open the box, pull out all the pieces including the instructions, and then proceed to spend hours trying to figure out how to put is all together. All those nuts and bolts are enough to drive anyone crazy.

What would life look like if this wasn't part of the equation?

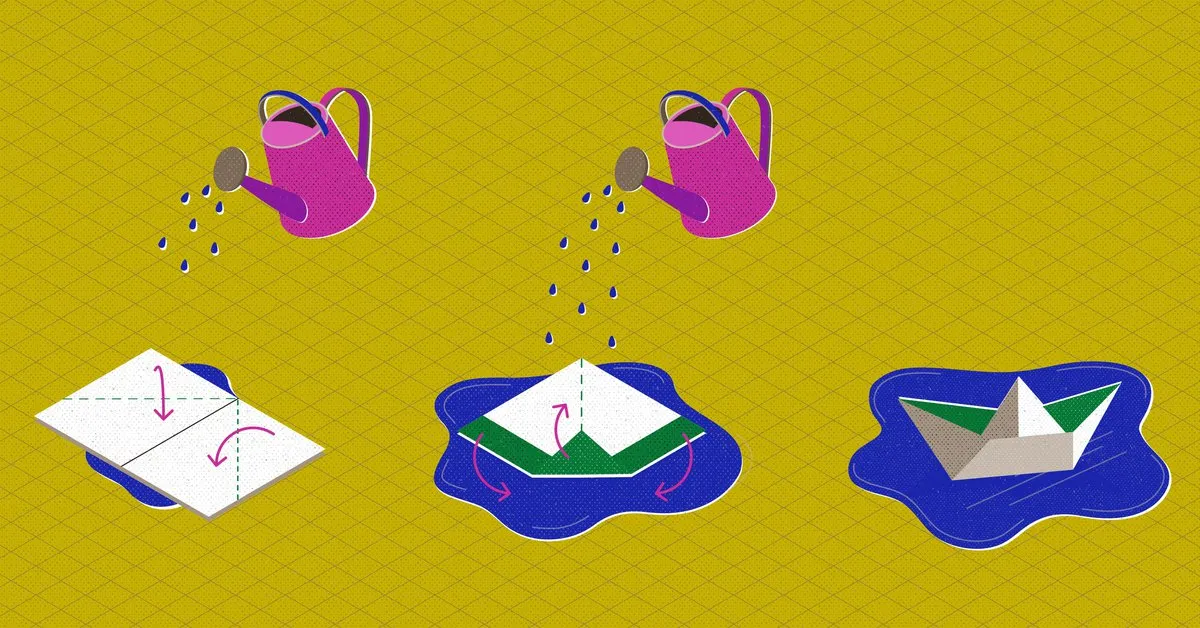

That is what entering the 4th dimension is all about. the same as before. However, the main difference is the material is programmed as to what shape it should take. Upon opening the box, the light hits the programmed material which then takes form on its own. The material also could be programmed to react with water.

This is all based upon nature and how the pinecone operates.

A naturally-occurring example of a 4D structure is the pinecone. Pinecones are covered with woody scales. The underside of each scale is made up of long, parallel, thick-walled cells which get longer when they get wet, and shorten when dry. Bonded to it on the other side is woody material with cells in a different configuration, which resists swelling when wet. This layered structure means that when it rains, the underside of the scale expands, and the top side doesn’t, which causes it to bend, closing the whole pinecone and keeping the seeds safe inside – held in store for a day with weather more suitable to pine tree propagation. In this example, the smart material is the moisture-swelling wood, but the 4D structure is the bi-layered scale.

Now researchers are trying to replicate what takes place in nature.

Thus far, complex structures are a bit difficult. However, progress is being made.

Here is a video that shows some of what can be done.

The reverse is also possible. Instead of assembling itself, the product could disassemble at the end of life. Part of the challenge with objects is to separate and breaking them for recycling. This could all be handled automoatically.

We are seeing progress due to 3D printing. As the number of materials the printers can handle expands, so do the possibilities of what researchers can create.

So how close are we to this all being a part of our daily reality? It is a while off. However, think of what it will be like to have clothing that adjusts as the temperature increases/decreases. What is possible becomes almost limitless.

Over the next decade, we will likely see the material sciences delving into many other areas which bring them towards the 4th dimension. It is this step that could start to tackle some major problems that are facing humanity.

Materials that change shape in this manner are key to pushing forward sustainability. As we progress into the space race, this will yield obvious benefits if space colonization is on the horizon.

If you found this article informative, please give an upvote and rehive.

gif by @doze