I am still trying to insulate my attic before the winter comes. I am sure it will be a tough one with the prices of energy literally going through the roof. So, I want to be sure that at least it doesn't go through my one.

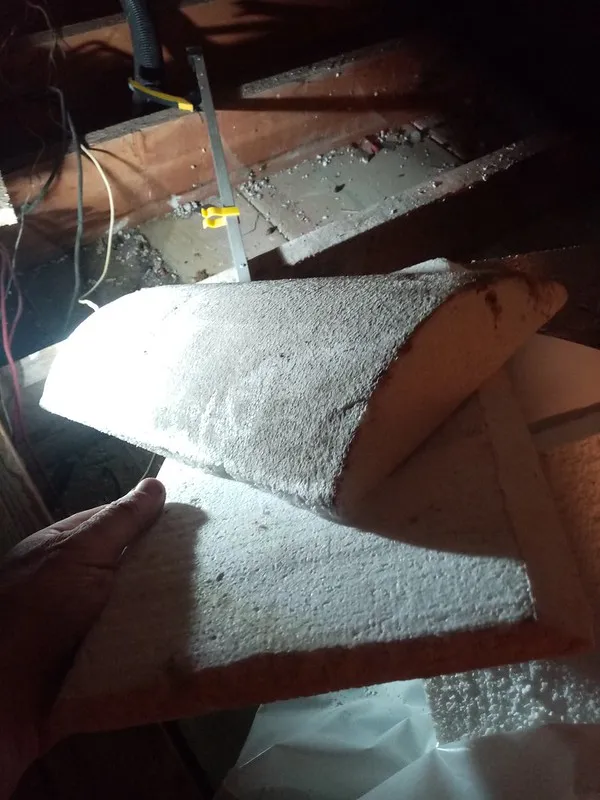

When my father built this house in the 50s early 60s he didn't consider insulation. Only as an afterthought and much later did he try doing something about it. He found some styrofoam cylinders from somewhere and decided to cut them into 1-inch/ 2.2cm slices and pack them in between the ceiling joists. Better than nothing, I suppose, but not really good enough. Our house, when I was growing up was freezing in the winters with ice forming on the inside of the windows.

We had an open fire to burn coal, wood and turf and this was to heat the whole gaff. Although it was cosy with twelve of us under its roof it is time to help it enter the 21st century and make it cosier still. I will be putting in 270mm/ 10.6 inches of mineral wool. I hope only to have to do this once so I don't mind spending time and money on it to get it right.

Out with the old

But, what becomes of all the styrofoam I removed. I want it out of the house because it is pretty useless and very flammable. I have 12 big sacks of it so far and it was taking up my whole shed.

Having checked the different disposal options it seemed that the only real one was to send it to the landfill. Styrofoam, made from polystyrene is really a great material but some of the things that make it so great are its Achilles heel. It is bulky and light and really bad for the environment but now that it exists I want it to continue on in the family tradition and use it somewhere.

In with the new

Luckily I am working for a plant company at the moment which provides a rental service to all the major corporations which have their offices in Ireland. We rent plants then. maintain them so they look their best. It is actually quite big business.

The work I mainly do is create bespoke planters, artificial displays and creative elements which can't be bought. I am also usually the one who has to sort out technical problems when they arise. I have given myself the title of CTO of the company even though I am a subcontractor (Happily so) I must say, It has been a good little sideline since Covid and now family illness has reduced my sculpture work.

There was a rush job with one client to get some plants into their place and unfortunately, there is only so much stock you can store. We had the large pots they wanted but not the plant pot inserts to suit them. The only ones we had were much shorter but perfect for the plants they wanted.

I saw a great opportunity to rid myself of my Styrofoam.

I could use it as packing to fill the empty space underneath. Tee Hee hee! Solving their problem as well as mine.

It was a bit tedious to do but I layered the foam into each base and brought it up just shy of where it needed to be on the 16 pots. Amazingly it used every bit of rubbish I had.

On top of this, I poured a layer of Leca (lightweight Expanded clay). This is normally used on the top of pots to make them more decorative and hide the compost and stores a bit of water. Funnily enough, it is made a bit like styrofoam but using clay. But I digress.

It is a good space filler and helped me level out the raised base to suit the insert.

Note to self: you need a new left work shoes.

Out of sight, out of mind

I know this probably wasn't the most interesting of revelations but for me to be able to dump all this foam was a very special part of my week. It's the little things which make me happy. Knowing that it is not going to the dump or incinerator for a little while longer helped me feel a little bit more environmentally friendly and it also saved me a bit of money while earning me a bit too.