In the past I have done a couple posts highlighting tools we use in the Lineman trade. First I showed you the Battery Operated Press A tool we use to squeeze connectors or repair sleeves on conductors. Then I brought to light what we use to get tools and material up and down the poles, the Hand-line.The last one I discussed was the Lineman Wrench and how much it has changed over my 15 years in the trade. Now there are a ton of different tools we use on a day to day basis when building and maintaining the electrical grid. But this next tool I am going to show you has to be one of my favorites. Because when you have to use it, you are doing what we like to call, Man-Work. A pole inaccessible by bucket trucks and insulators that are so long due to the voltage that you cant lean out off the pole far enough to get to the end the insulator. So there is a tool for that and here it is,

The Diving Board

So I was just looking though some old work photos from back when I was working a 115,000 volt Transmission job on the Feather River in California. The crew running the job got all the poles changed and they brought a couple more crews in for wire pulling day. Detach the wire from the insulators, pull the new conductor in with the old, then re-attach the new conductor to the insulator. Sounds simple enough right? LOL

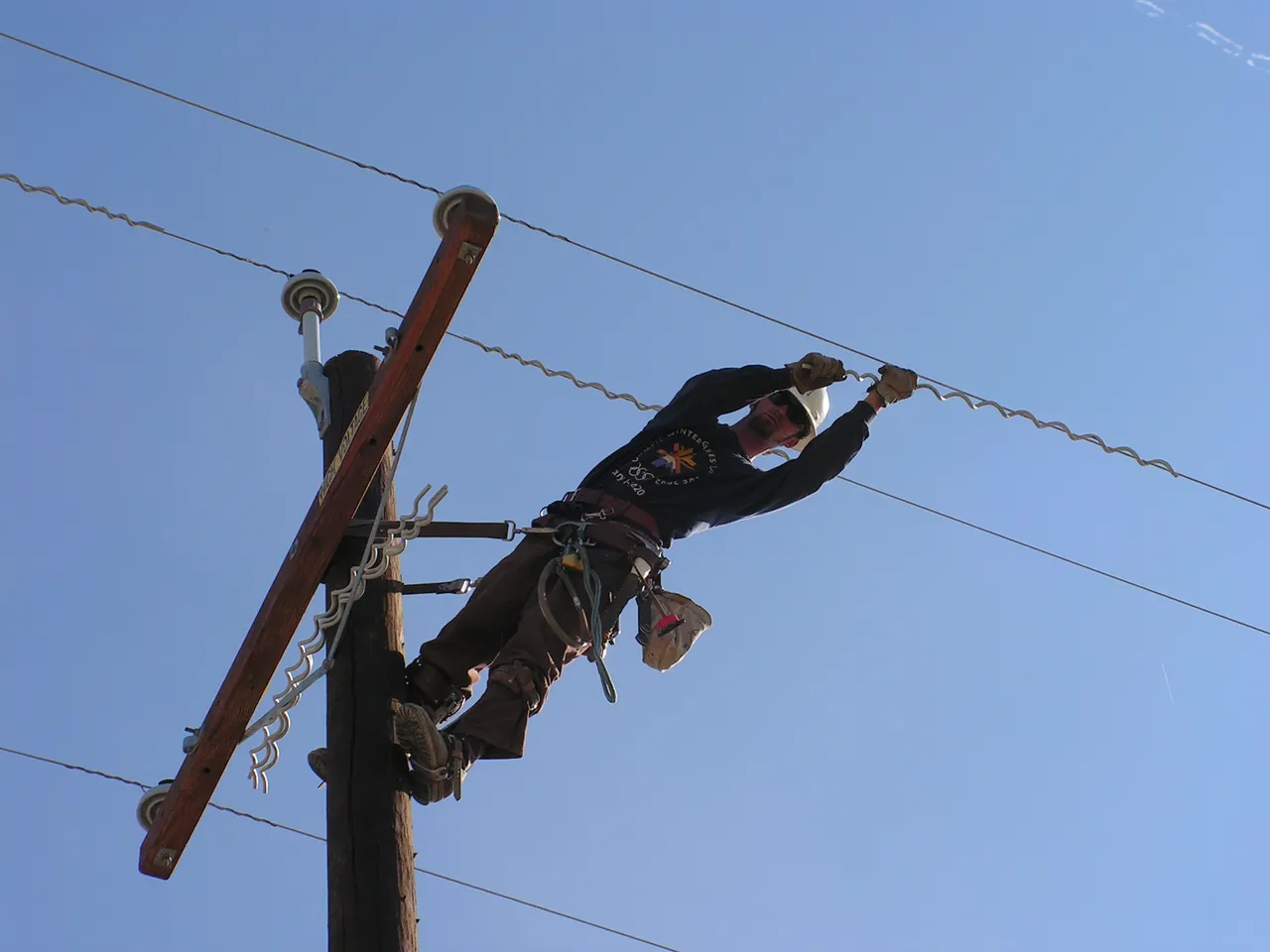

So we use the Diving Board to get the extra reach we need off the pole to get whatever work we need to get done. If I was 10 feet tall there wouldn't be an issue. Having just the balls of your feet pressed against the pole you can only reach out so far. Now try performing any work in that horizontal position with all that force from your belt around the pole pulling at your belt around your waist. Not fun. I have had my belt slide down off my waist while leaning out and it will make the cheeks clinch a bit. It takes a lot of force to keep your boots from sliding down the pole. Since for maximum reach you done have any gaffs in the pole, Your feet will only slide so far then hopefully your gaff on your lower foot will dig into the pole.... I have no idea if that makes sense to anyone but I dug up this old photo from back in my apprentice days to kind of show what I am talking about. Granted I am not completely horizontal but you get the idea... right?!?!

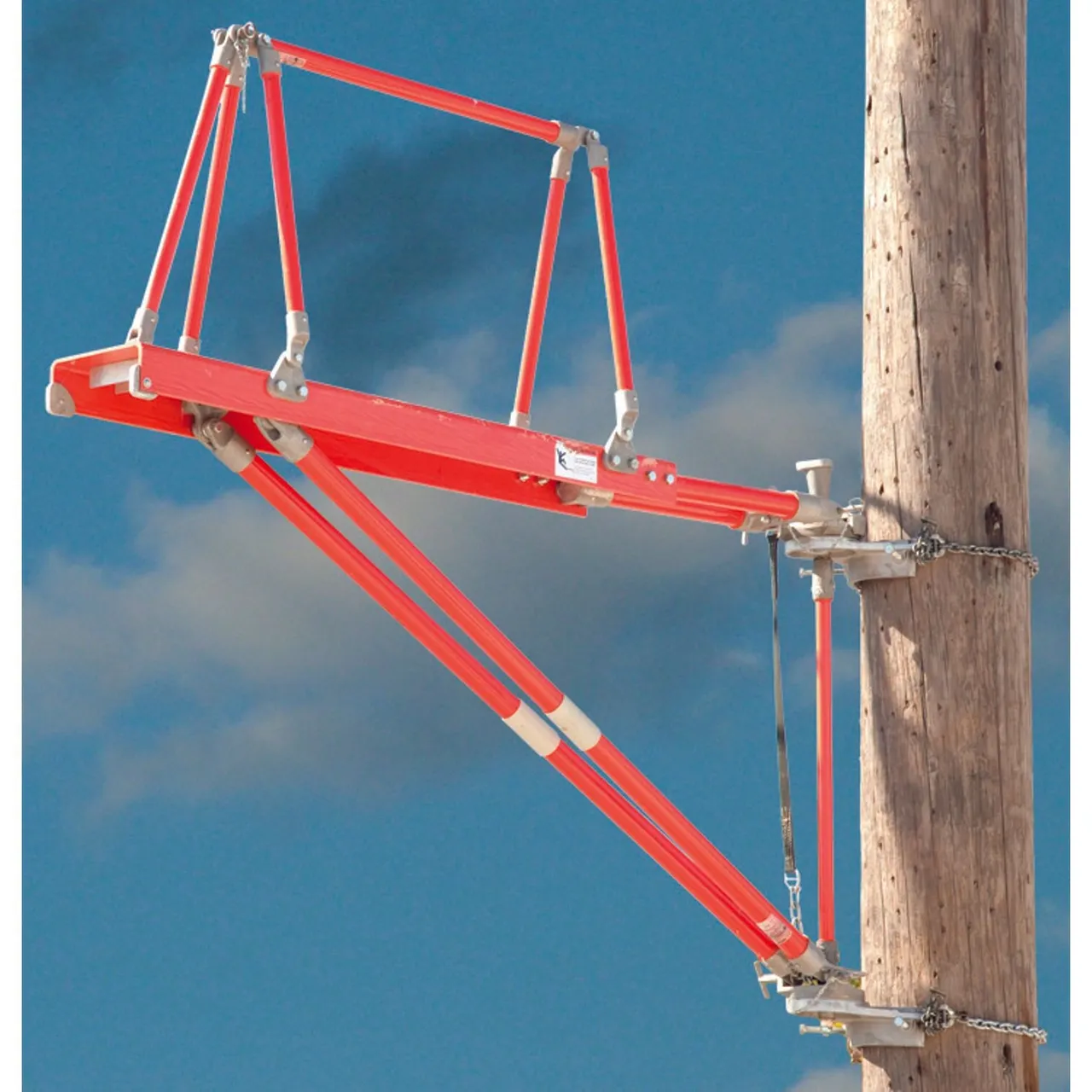

Oh ya back to the Diving Board... they can range in length but the ones I used were 8 feet long. Basically it is like walking the plank on a pirate ship. You connect your safety harness to the pole and walk right on out there. The Diving Board has a steel bracket that goes against the pole and is in the shape of a V and attaches to the pole with a chain.

Then below that is had a sort of kickstand for vertical support. Without it, the diving board would have very little support and stability. I found this short diving board in the shop to show you guys basically what it looks like.

First, we need to take a ride to the pole, since there are no roads close to these poles a helicopter is the fastest way to get there.

That's not our pole, the road is too close

The helicopter drops us at the base of the pole and leaves to go bring us our diving boards and other tools needed. It is all loaded in a big steel basket and dropped off at the base of the pole with us. One at a time we climb the pole and then have another guy send up the diving boards. 2 of us get the diving boards all setup and once they are in place and all your tools are up in the air, its time to walk the plank.

The photo opportunities were very minimal, we had the toughest poles to work on the whole job. I guess that is what you get when you work for a Foreman who is well known to flat out get it done! To give you a little perspective of what it looks like after we "bumped" in a piece of wire and let the insulators hang in order to pull the new wire in. This structure is called a Dead-end. The wire stops on each side of the pole and has a jumper that connects the two sides. Where those bulges are on the upper set of wires is about where the end of the insulator would reach. This is what is looks like while we wait for the wire to get pulled in. We sit and watch the travelers (rollers, dollies, wheels..) to make sure they are working correctly and nothing gets hung up. Those Diving Boards sure stick out there don't they?

It seemed no mater what we did and how we positioned the diving boards, the guy on the upper one had to work sitting on his ass. Which was kind of nice in a way but also a pain in the ass in another. This is my good Buddy Hugo sitting down on the job being lazy. Cool little story, We actually went to lineman school together before we actually got in the trade. We both ended up working in different areas for PG&E. Then after we both topped out and got our journeyman cards we ended up being on the same crew working transmission and we’re helicopter fly partners. Pretty cool..

Yes that is me getting the rigging on to be able to cut the wire and connect it to the dead-end shoe that is attached to the insulator. If I remember right, those insulators are about 5 feet long and made out of a polymer. I am glad they weren't glass or porcelain... Heavy!!!

Looking to the next pole we have to work on.

I am not sure if you can tell but from day one of this week long wire pulling job, there had been a fire just on the other side of the hill from us. The sky kept getting worse and worse and the air was terrible. But we just kept working and getting it done. This is a photo that an apprentice took, no filters that is the actual color of the sky. Also it gives you a great view of how we work on the Diving Boards. After we finished with what we need to do on one wire, we have to re-position them around the pole to work on the next one, then the next.

If you look closely at the point where the diving board meets the pole, you can kind of make out the kick-stand I was mentioning

Here a a photo of us making our way to the job on the first day. Our job was on the other side and the fire service guys held us up for a bit since the fire was so close to the road. We weren't 100% sure we were going to do this wire pulling job or not at that moment.

Never mind the fire, let's get back to the Diving Board. Typically when you have to use Diving Boards you need to dust them off because thy haven't been used for quite sometime.

Shoot I remember having to ask everyone if they knew where they were at. It took a few days to track them down. Once they were found, we gave them a good inspection and made sure the chain binding mechanism is in good shape and working properly. This style of Diving board is just made out of wood and when you get on the end they are a little bouncy, but not bad. When you are using them on a skinny wood pole... it’s a fun ride. The pole flexes a bit and then add the little bounce of the Diving Board and things really get moving. You can have some fun messing with the guy on the other side. Bounce him around while he is trying to put some small nuts on some bolts. Lol.

They also work on steel poles, which during this job there were a lot of. The Diving Board felt way more stable on the steel pole rather than the wood. No flex in the steel.

Right on the End

I have also used a different kind of Diving Board, which is called an Insulated Platform. I used one of these in a back yard to work on energized lines and change insulators. These are really nice and as you can see there is something you can straddle with your legs to give you a little extra balance. Plus there is a release knob that you lift up and the whole platform swivels around the pole. Don't get me wrong, the first time I threw on the Class 2 Rubber Gloves and grabbed a hold of 12,000 volts while standing on this platform was a bit nervy. You can put one on one side of the pole and one on the other and get some hot work done on these.

source

sourceEven though the Diving Board doesn't get used as much as most tools, its still a great tool to have. When you look at the length of the insulators, the length of the arm the insulators are hanging from and now finish off that triangle to the pole where a Lineman would be standing. It's a looong way out there... Also depending on what kind of structure you are working you can use as many of these diving boards as you can fit on there.

I am on the top right sitting on my ass

Well I could blab on and on about this specific job and how much of a pain in the ass it was but also how fun it was. At the end of everyday we all would gather around in the courtyard of the hotel, crack some cold ones and talk about the day. That is one thing lineman do best. Find a better way to do stuff and make the job easier.... over a few cold beers. Plus those old Lineman have some funny stories to tell

Again I really hope you enjoyed seeing another tool of the Lineman trade. There are so many tools we use to build and maintain the electrical grid and I thought this one would be a good one to share. Thanks for hanging out

I am on the left finishing up the last connection

Hive On

and

source

Now That is Funny

Right There