I have been hit and miss when it comes to sharing with my fellow Hivers what is it like being High Voltage Journeyman Lineman. Sharing with the Hive community a little insight as to what we we do to keep your lights on, A/C pumpin’ and them servers runnin’ full blast. So, here I sit between outage calls on my couch relaxing… and figured, what better time to do another long awaited episode of A Day With A Lineman.

A Day With A Lineman #21

Almost Lost It…

It seems kind of weird to me for a small utility company to to do maintenance work on a large utilities facilities. Pudget Sound Energy (Seattle area) owns a wind farm about 45 minutes away from one of our service centers. They contracted us to provide the maintenance on their overhead and underground powerlines. Not the windmills. Every so often we have to dig up bad underground cable and repair it. Knock frost off of their 230,000 volt powerlines to keep them from breaking or damaging the structures. Among other things.

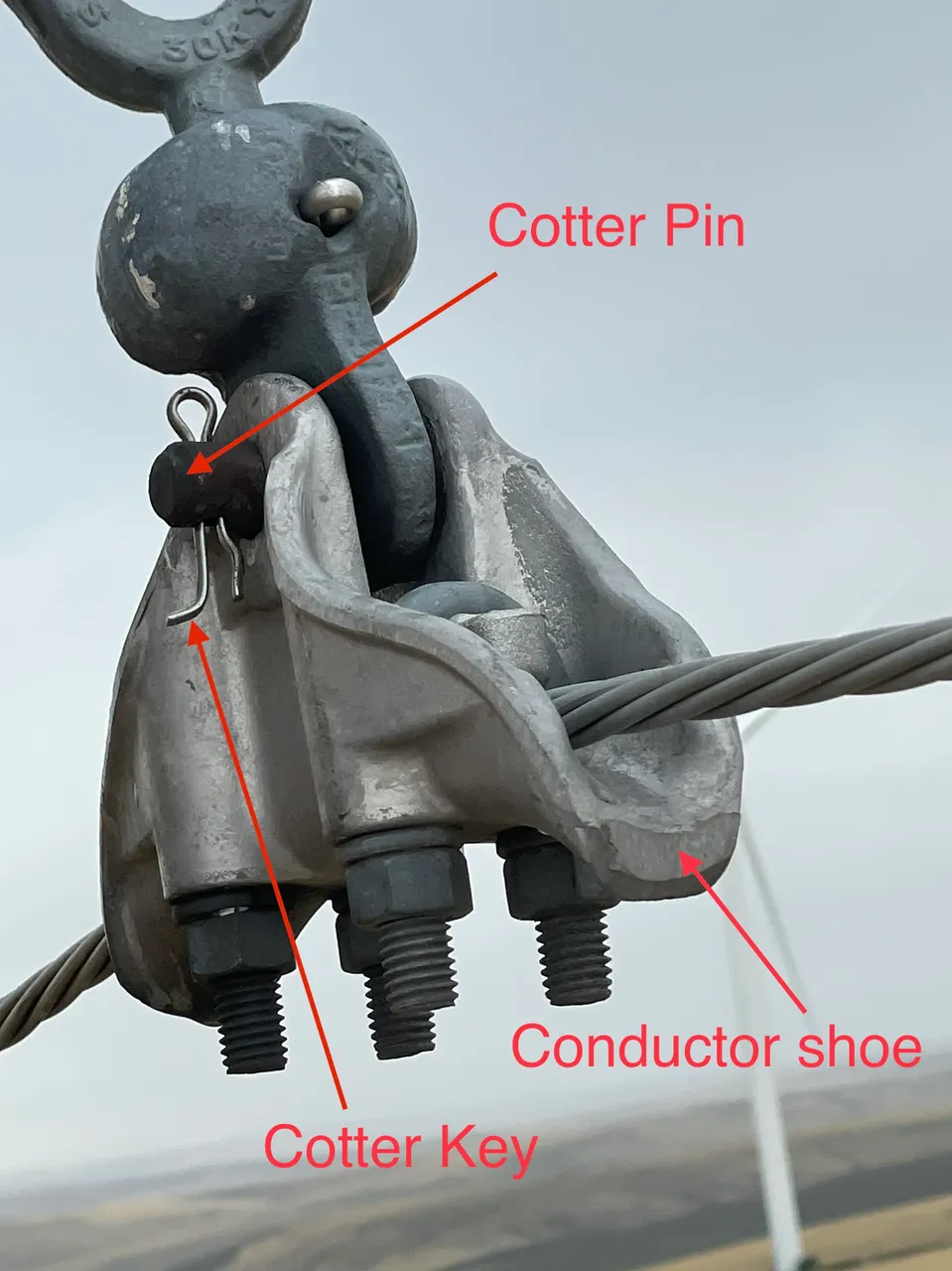

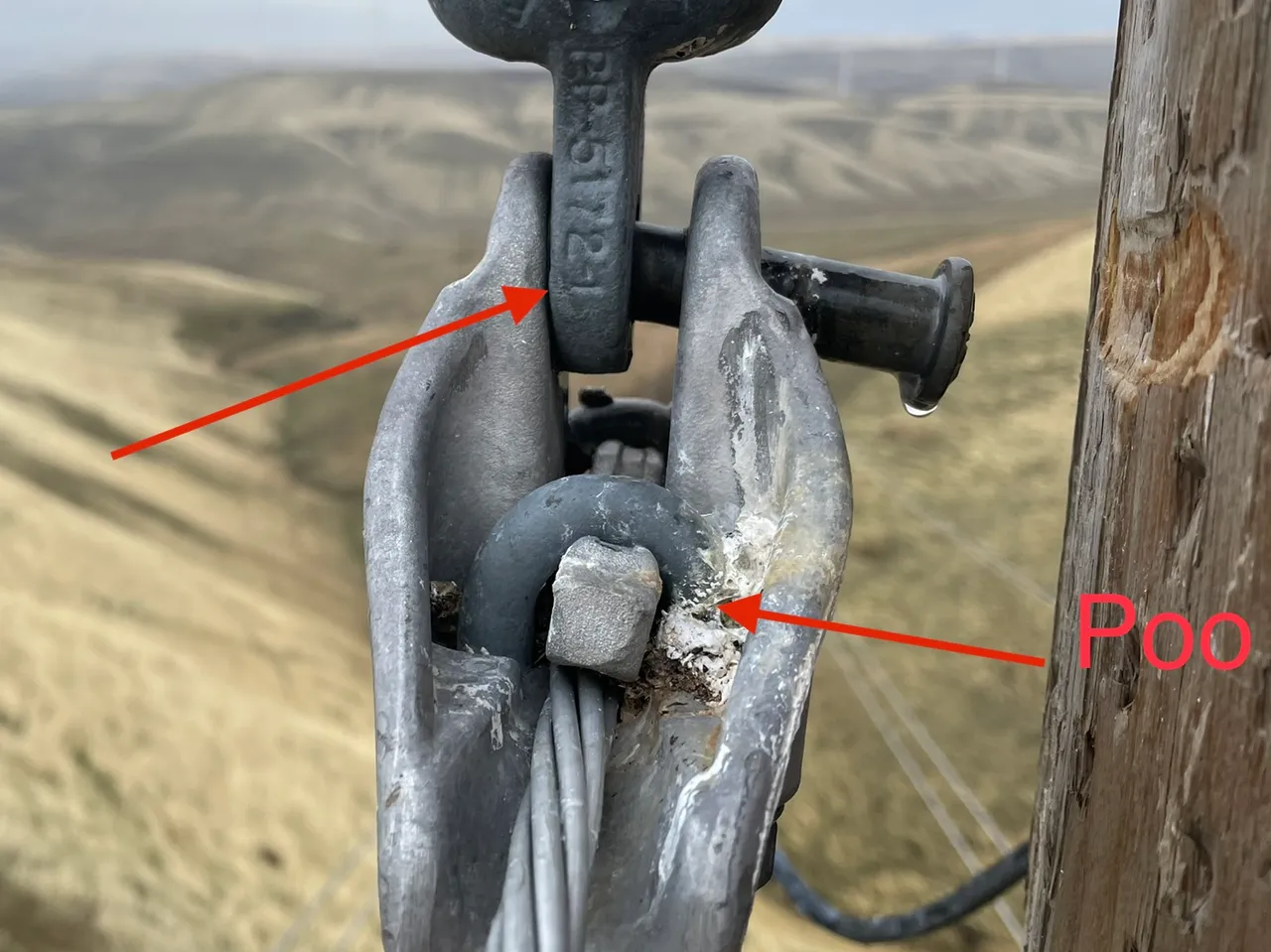

This go around, someone at PSE had a good eye noticing a cotter pin was about to fall out of the conductor shoe that holds the static line to the pole above the 230kv line. The static line is almost like a lightning rod in some cases, being that it is at the highest point of the structure. Most are made of stranded steel. Yet, I have installed static lines with fiber optic cables built in the core of it. The outer strands are steel and the inner core is fiber optic. They get a little weird if that kind of static wire gets a kink in it…

Can you see it?

Somehow the cotter key came out or broke and the cotter pin nearly walked its way completely out. The constant wind creates tons of vibration and can be very destructive even to steel materials. It will vibrate nuts off of bolts that were tightened down beyond torque spec.

There is a cotter pin and a cotter key that hold the conductor shoe to the structure or insulator. We Lineman just call them shoes… because well… they come in different sizes and they… kind of resemble a shoe…??? Actually I have no idea why they are called shoes in the trade but they just are. Just call out the wire size and say what type of shoe you need and Ta-Da

This is after the repair. We have the cotter key in with and extra bend to keep it from walking out

Every time we have to go to areas where they have windmills the wind is flat out getting after it!! It’s amazing that is doesn’t blow these 300 foot tall with 3-100 foot blade windmills down. You better have 2 hands on your truck door and a good king-fu grip on it or the wind may rip the door clean off. But if you need to dust out the inside of the cab just open both doors. This time the guys at PSE were nice enough to shut the giant fans off so it wasn’t windy at all 😉😉

After completing the switching to de-energize the 230kv line we made our way to the first H structure with the cotter pin coming out.

Got the 95 foot bucket truck setup and installed out protective grounds. It took 10 times longer to ground the lines than it did to do the actual work. That’s how it goes sometimes when you are working on big structures with big wire and transmission voltages.

The first cotter pin we needed to get back in place looked like the cotter key had been broken off. The side of the shoe had some pretty good groves in it from the cotter key.

One would think with the weight of the wire in the shoe pulling down on the cotter pin that there would be no way for it to come out. Severe winds can cause the power lines to start Galloping or bouncing up and down. Which takes the weight off the cotter pin and allows it to move.

source

source1/2 an inch more and this cotter pin would have came out. Sending the static line slamming down on the steel arm that supports the conductors carrying 230,000 volts. Then depending on where it lands and which way the wind is blowing it could easily end up contacting the energized lines and causing an unexpected outage or fire.

It took about 2 minutes to lift the wire with the winch on the 95 foot bucket truck, push the pin back in place and install a new cotter key. Then another 1/2 hour to remove all the protective grounds. Then it was onto the next one.

Then the clouds rolled in and we started to get a little wet from the rain. We needed to hurry and get the next one done before the ground gets to greasy and we can’t get the 95 foot bucket truck out from the bottom of this gradual hill.

We did manage to get the big bucket out without any issues but we had one last cotter key at a different structure to push back in. It was down a pretty steep slope and there was no way the 95 footer was going to get out of there. So we took one of our small buckets down and used an extendable hot stick to get the cotter key pushed back in place. Sorry no photos, the rain was really starting to come down. The rain made the hill so greasy that the small bucket truck was stuck on flat ground. Yes, even in 4 wheel drive. So I parked at the top of the hill with my bumper mounted winch all the way out. Hooked a long rope to it and hooked the rope onto the stuck bucket truck’s winch which was all the way out also. It must have taken us about 2 hours to get that dang truck outta there. I said just leave the truck there and we will pick it up when springtime comes…

Wouldn’t you know it, just after we got everything cleaned up and put away the cloud cleared out and we could see blue skies. Well at least we will have a nice 1-45 minute drive back to the shop.

Stick around if you would like to see and learn a little more about being a Lineman working on the high voltage power lines. I’ve had a lot going on in my life lately and I post whenever I have time. Which isn’t very often… Thanks for stopping by and I hope to post again soon about my career as a High Voltage Lineman

Your Random

Dose of...