As humanity sets its sights on establishing a long-term presence beyond Earth, one challenge looms large: how to construct durable, functional structures on distant planetary bodies using available materials. To address this, NASA is advancing technologies that leverage in-situ resources—local materials such as lunar or Martian soil—to reduce reliance on Earth-based supply chains.

A central initiative in this effort is the Moon to Mars Planetary Autonomous Construction Technology (MMPACT) project, operated by NASA’s Marshall Space Flight Center in Huntsville, Alabama. Backed by the agency’s Game Changing Development program, MMPACT is investigating how robotic 3D printing systems can be used to autonomously fabricate structures like habitats, landing pads, and radiation shields using extraterrestrial regolith as a building material.

Collaborating with academic institutions and private companies, the MMPACT team is refining methods for transforming regolith into usable construction material. This includes identifying suitable binding agents—such as water that could be extracted on-site—and assessing the mechanical properties of regolith-based concrete. The research traces back to work by Dr. Behrokh Khoshnevis of the University of Southern California, a pioneer in large-scale 3D printing and a former participant in NASA’s Innovative Advanced Concepts (NIAC) program.

Dr. Khoshnevis introduced techniques like Contour Crafting, a process that extrudes molten regolith and binders to form solid structures layer by layer. This approach allows for the creation of robust infrastructure elements without human intervention. He also developed selective separation sintering, a method for producing high-precision items by applying heat and pressure to powdered materials—useful both in low gravity environments and aboard spacecraft for making tools or replacement parts.

NASA’s investment in extraterrestrial construction is also finding applications on Earth. Dr. Khoshnevis founded the Contour Crafting Corporation to commercialize the technology for terrestrial housing and infrastructure. Similarly, ICON, a company based in Austin, Texas, is adapting space-proven additive manufacturing methods for residential construction.

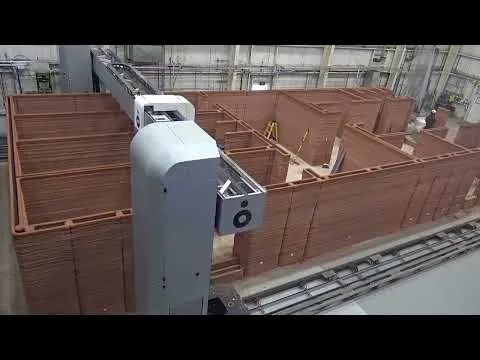

ICON has partnered with NASA on several fronts, including the 3D-Printed Habitat Challenge, which spurred innovation in space-based construction methods. In 2021, the company built a 1,700-square-foot habitat prototype named Mars Dune Alpha at NASA’s Johnson Space Center in Houston. Designed to simulate conditions on the Red Planet, the structure will host analog missions—such as the Crew Health and Performance Exploration Analog (CHAPEA)—through 2026, where four individuals will live and work in the habitat for year-long stints.

ICON’s broader efforts include developing the Olympus system, a large-scale construction platform capable of utilizing lunar and Martian resources. The system employs an advanced method called Laser Vitreous Multi-material Transformation, where high-powered lasers melt regolith to form strong, ceramic-like building components. These structures are engineered to endure extreme temperatures, abrasive dust, and radiation levels on planetary surfaces.

To better understand how lunar soil analog behaves in low gravity, ICON recently conducted the Duneflow experiment aboard Blue Origin’s reusable suborbital vehicle. The test, which took place in February 2025, recreated lunar gravity for about two minutes—enough time for researchers to compare simulated material behavior with that of genuine lunar samples returned during the Apollo era.

NASA’s push toward off-world construction is yielding technology that will be vital for future missions and is already influencing Earth-based applications. Through projects like MMPACT and its partnerships with visionary engineers and companies, the foundation is being laid—literally and figuratively—for a future where humans can live and work on other worlds.

Should Earth-based applications of space-developed technologies (like 3D-printed homes) be a bigger focus of NASA’s public outreach or funding justification?