If you've been reading my posts, you may have gotten the impression that I do a lot of repairs. That impression would be correct. Aside from doing all my own repairs, I usually pick up a few repair jobs for extra money in my off season, and of course family and friends swing by constantly with 'could you look at my...' questions.

Back before my 35th birthday, when I had more time and energy than disposable income, I would happily break my knuckles on these jobs with an adjustable wrench, a chewed up #2 phillips head screwdriver, and a butter knife. Now that I'm closer to 50 than I am to 40, my income is up, but my free time and energy are down, so I buy tools. The best money I've spent on tools has been the money I've spent on air tools.

If you've ever used an impact wrench, probably the first thing you asked yourself afterward is why you wasted half your life turning wrenches. In terms of quickly disassembling anything held together with nuts and bolts, there is currently no comparable tool I'm aware of that even comes close to the speed and safety of an impact wrench. I will also give a loud shout-out to air nailers, which can save an insane amount of time and energy when assembling anything made of wood.

Many air tools have rechargeable battery operated equivalents these days, and the lithium-ion tools have very impressive performance. They are often smaller and lighter, and without the air hose dangling can be a lot more useful for getting into tight spaces. I use a lot of these tools as well, and they'll get their own post. I wanted to post about air tools first for a few reasons. First, they are generally cheaper. Second, they tend to be more durable. Third, they are more weather resistant. They also tend to be easier to repair.

Every power tool needs a power source, and for air tools, the power source is your air compressor. Like with most things, bigger is usually better, and this post is supposed to be about the great deal I found on a bigger compressor, not a dissertation on power tools.

For years, I've been getting by with the first compressor I ever bought. It's a 6 gallon portable compressor with a max pressure of 125PSI, which I initially bought just for inflating tires and blowing dust out of things. It does the job well, but slowly. It will run air tools, but for most of them, you have to stop frequently and wait for the compressor to build enough pressure. The volume of air your compressor will produce is measure in Cubic Feet per Minute, or CFM, and is usually listed as (x)CFM at (y)PSI. My little compressor delivers about 2 CFM at 90 PSI, which is the operating pressure of my impact wrench. To operate continually at that pressure, the impact wrench needs something closer to 4.5 CFM, which brings us at last to the object of this post.

I found this sweet little gem in one or another of the online classified ads where I like to do most of my big ticket item shopping. Being a repair guy, I can often find ridiculous deal on item that need very minor repairs, like this compressor. It was listed at $80, and would retail new for at least $250, generally closer to $350. It also came with that blue air hose, which was brand new and worth about another $30.

One nice thing about air compressors is that the fittings have been fairly standardized for some time, so finding extra parts for anything broken in the piping is usually pretty easy. I made sure that this would turn on and build air before I bought it. As long as it does that, basically anything else wrong with it will cost less than $20 to fix. This looks like it's been cobbled together, but nothing was broken, and it didn't look like there were likely to be any stripped threads. Once I saw it worked, I didn't even haggle over the price. I know, I'm going soft, but hey, it's the holidays!

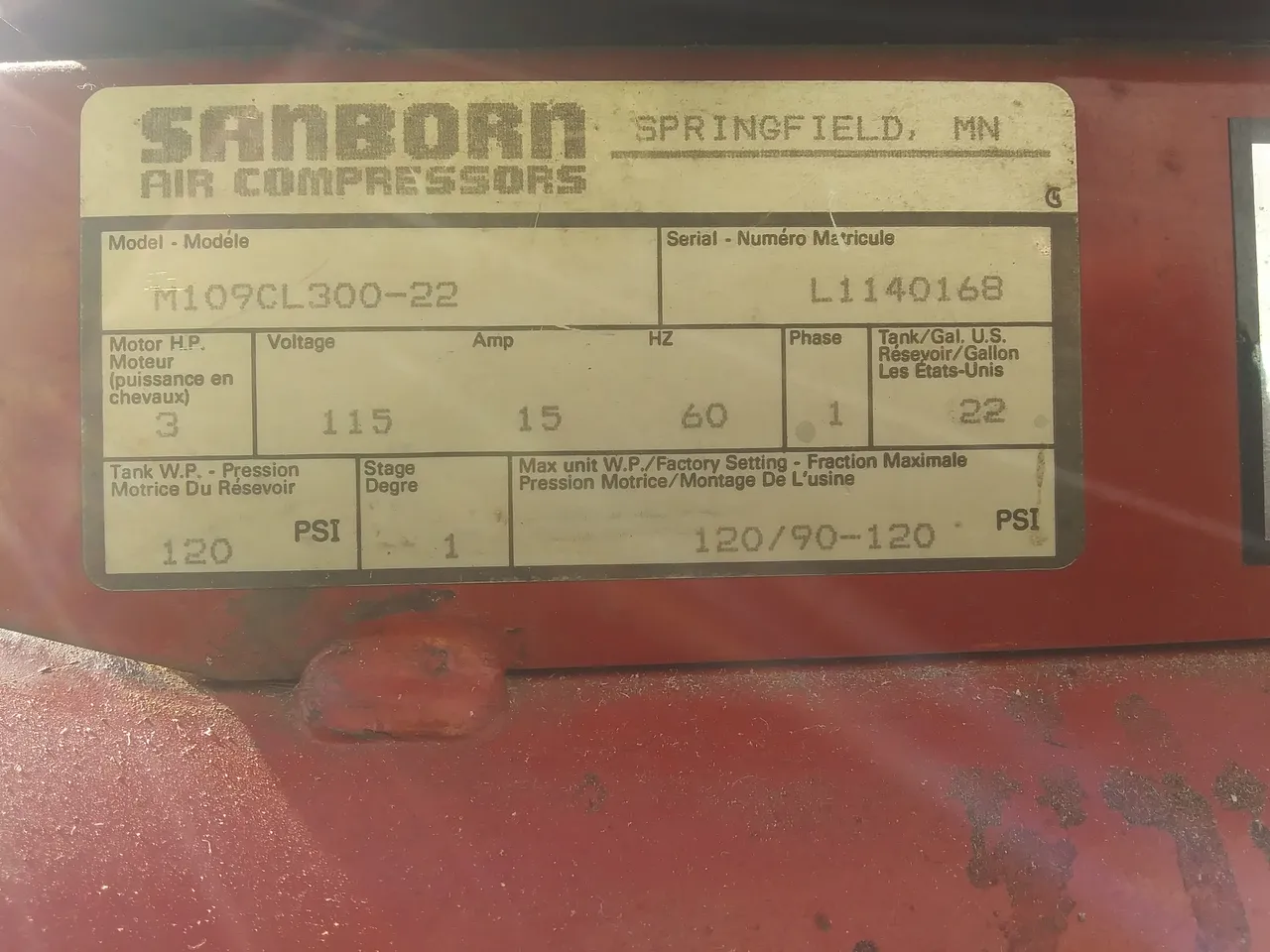

The tag didn't tell me the CFM of this model, but I know that most compressors on a 22 gallon tank will do at least 5 CFM at 90 PSI. I looked up this model online and found that it claims 5.7 CFM at that pressure, so it should meet all my needs.

This broken pressure gauge was the only problem mentioned in the listing, which seemed a bit too good to be true (it was), but as I said, any repairs to the piping will be cheap.

It so happened that I had an extra one already. I had to replace one on my small compressor, and had found these in a clearance bin, so I bought two at the time.

I could see by the gathered dust that nobody had been checking the oil in the compressor, so this was the first thing to check when I got it home. The cap was pretty well stuck, but came loose easily with a wrench. The oil was filled perfectly to the top and still looked nice and clean, so no worries there. I haven't bought compressor oil in a while, but it can be a little pricey and sometimes hard to find. I wouldn't have considered this as a repair cost, filling and changing oil is part of regular maintenance on compressors.

I put the new gauge on and readjusted the pipes so the quick connect was more accessible, and so I could use the 'plug' bolt as a handle to hold the 'T' when changing the quick connect, which I sometimes do for compatibility with other people's tools if I take my compressor out to a site. With all the known holes plugged, it was time to turn it on and build some pressure. This is where the next problem became apparent.

Everything worked great up until about 80 PSI, then the belt that runs the compressor started slipping. Tightening this is pretty straightforward, you simply loosen the bolts that hold the electric motor, pull the motor back until the belt is tight, then re-tighten the bolts. After tightening this up a bit, it built right up to about 123 PSI and shut itself off as it should.

It also came with a cobbled electrical cord, which worked but wasn't very safe. Since the plug was already a repair end, all I had to do was remove it, cut the cord back to where the insulation was properly intact, and reinstall the plug.

With all that done, it was time to take it outside and actually use it. Well, I tried anyway. The 3 HP electric motor draws too much current to work properly with a long, light (14AWG) extension cord, and it would only build to about 80 PSI before the motor bogged down and tripped the internal breaker. I do have a 12AWG cord, but I'm currently using it for a heat lamp in the chicken coop. Part of my problem was not just the motor, but the pulleys were out of alignment, causing extra drag on the belt. I had to take the guard off to get to these, which was easy enough. The pulley on the compressor is bolted into place and doesn't move, but this one on the motor has a hex head set screw that loosens and allows the pulley to slide easily. Once I got this lined up, it would build up to 100 PSI on the long cord, but still not all the way, so I had to move it back closer to the shop and run out extra air hose.

I thought about leaving the belt cover off, since I'll probably end up just leaving this one inside as my shop compressor and use my smaller one to take out on jobs. These belts and pulleys seem safe enough even when they're moving, but I've seen too many things go too far wrong too fast... the cover is going back on.

Naturally, one of the reasons the cover came off so easy is that it's pretty flimsy and I bent the hell out of it. The good thing about flimsy is that it can be bent back into shape easily. I had this flattened back out in just a couple minutes with a pair of needle nose pliers.

After all that, it runs just like new. Not only does it produce more than twice as much air as my old one, it is also quite a bit quieter, which makes it much nicer to leave in the basement. The old one would sound like someone was running a lawn mower in the basement when it turned on, this one doesn't make much more noise than the washer.

I could easily do another 1000 words on air tools, but I'll save that for another post. I don't have any good pictures for that post yet, anyway. I hope you learned... got inspired... something... yadda... you've heard it before 🤣

Hope to see you back for more!