I did a lot of casting figurines from molds before. But I did my casting molds by hand.

Today I decided to do mold by a 3d printing tech.

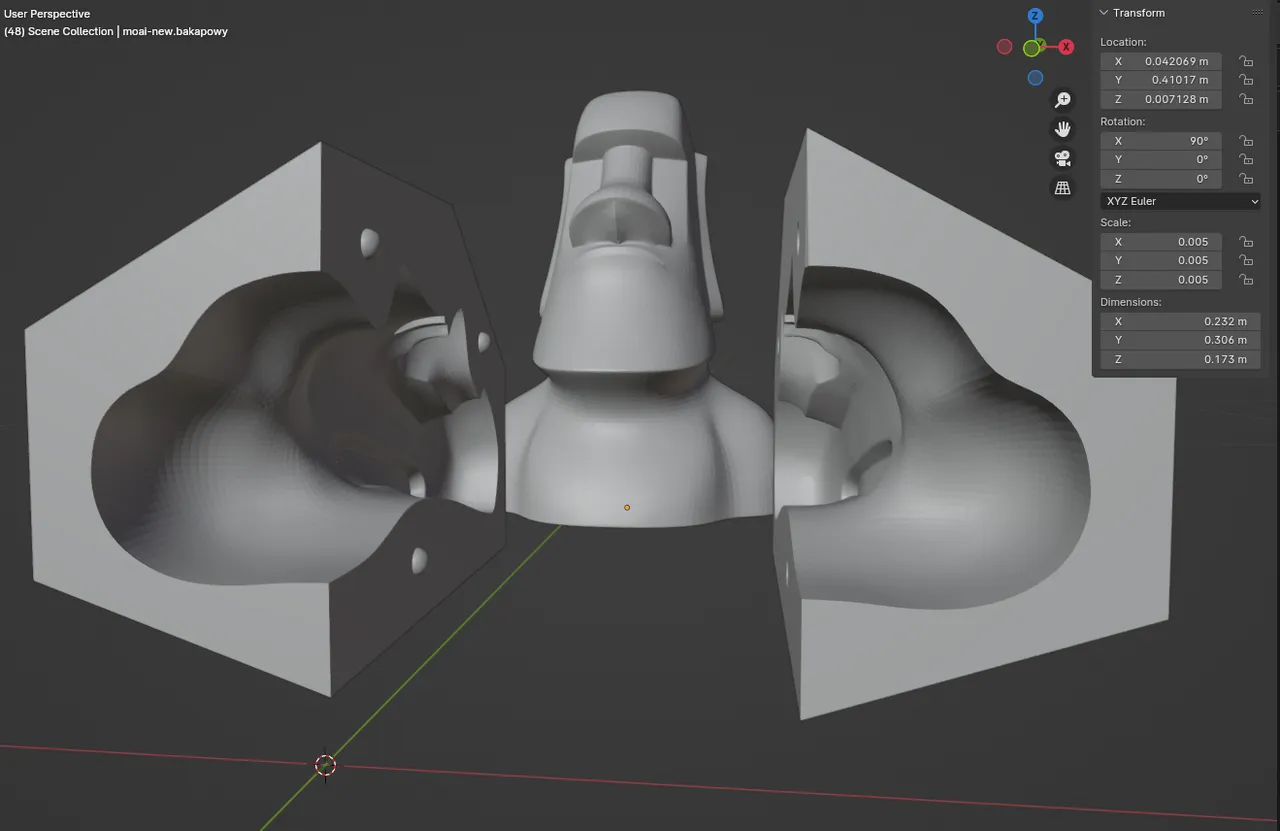

My initial project involved sculpting a figure that would eventually take physical form as a concrete moai through a casting process.

During my exploration into 3D printing, I delved into the realm of design using a versatile tool like Blender.

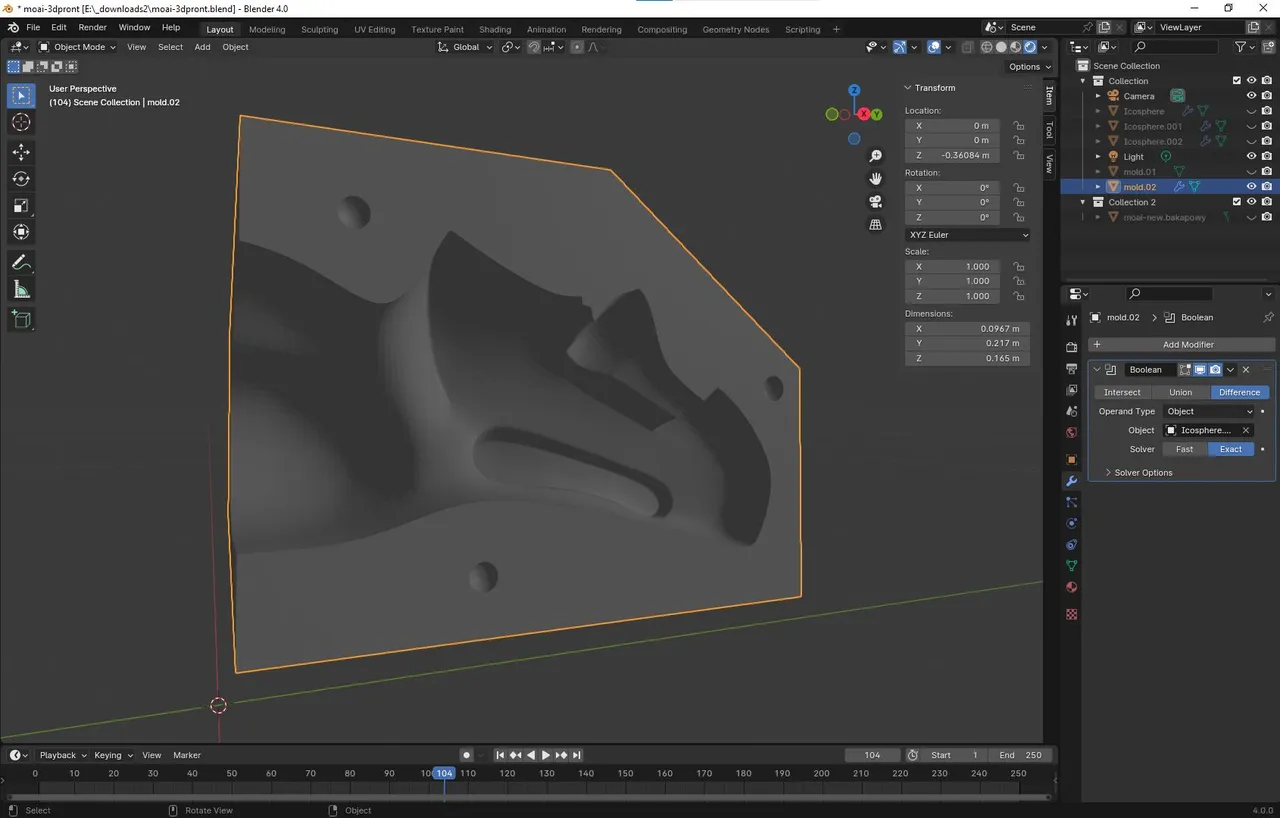

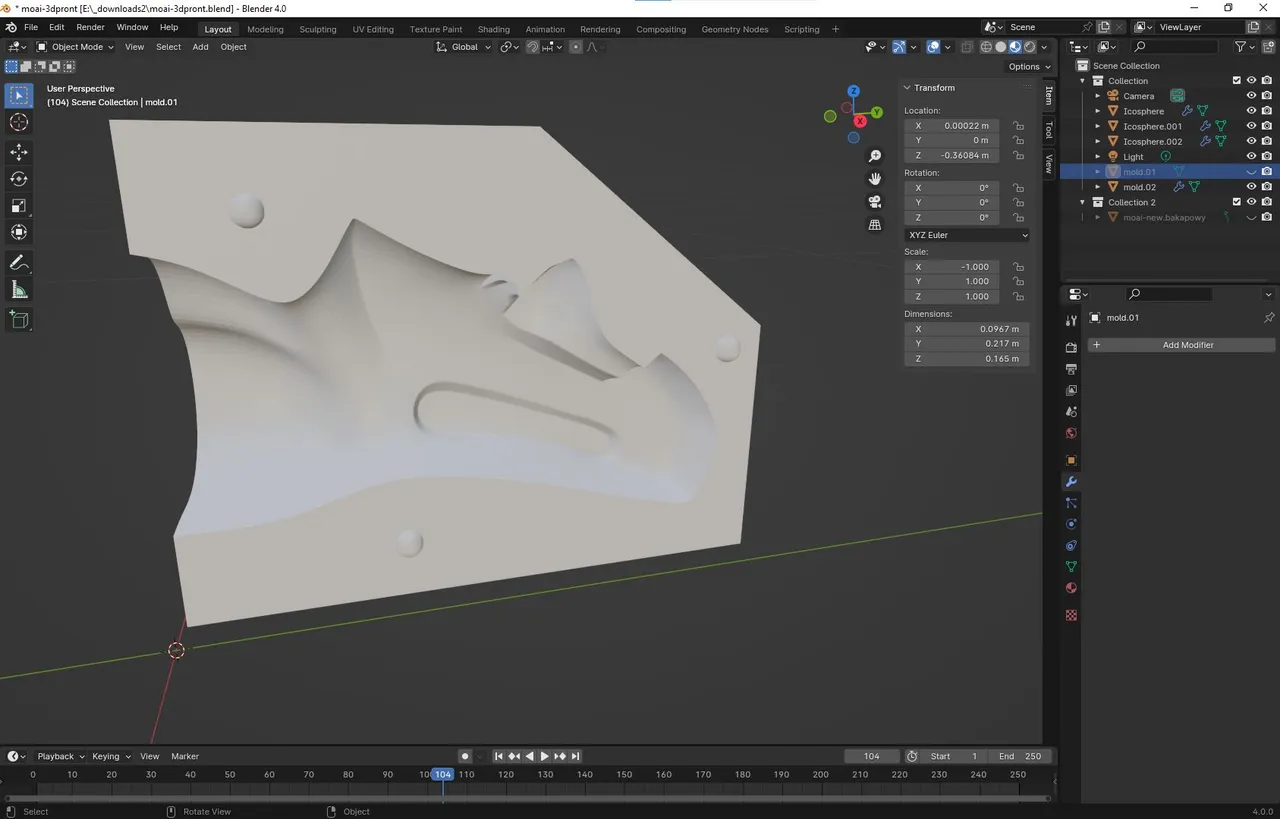

I decided to tackle the challenge of creating a three-dimensional inverse of my original figurine, essentially its absence in space :). This required a meticulous process of transforming and refining the digital model in Blender. Working on the digital mirror counterpart introduced me to the intricacies of spatial reasoning and emphasized the importance of considering printability from all angles.

Blender is a pretty solid tool once you get past its basics. It has become my go-to digital sculpting chisel. It turns out that the key to successful 3D printing is ensuring the model is "watertight." It can't have any holes or intersecting lines or planes, or else the printer is likely to encounter issues. This endeavor not only enhanced my proficiency with Blender but also underscored the significance of adaptability in 3D printing.

Currently, I'm awaiting a quote for my project. The figure is intended to be 20 cm tall, and I plan to produce multiple copies using this mold.