Welcome back to yet another edition of

A Day With A

Lineman

A Day With a Lineman is series about what High Voltage Lineman do and encounter to keep the lights on for our customers. Also some tools and techniques we use to build and maintain the electrical grid. It’s not as easy as just flipping a switch… Ta-Da the lights are back on.

Yay my favorite place to go… the cattle feed lot!! A call came in about an outage at the feed lot. It didn’t take long to figure out what had happened. The pole was on fire and the top 10 feet of pole had broken off and balancing there. We believe that due to the amount of poo-poo dust floating around that one of the porcelain cutouts (these hold the protective fuses for the transformers) had failed and electricity had tracked down it to the pole and started the pole on fire.

After burning for some time, the pole got weak enough and broke. The weight of the wire along with the side tension, caused the top of the pole to break and tip over. The aluminum wire with a steel core has about the same diameter as a U.S quarter. Then you add some side tension and things get a little heavy…

With a new 50 foot pole and other material loaded, we headed towards the feed lot. No need for directions, you can just smell your way there…

The broken pole

When I mention about side tension this is what I mean…

The pole isn’t in a straight line with the 2 poles on either side of it. The pole is set out of line for various reasons. Whether it be a road, the terrain, or various utilities put underground. So the wire wants to be in a straight line, putting a lot of side tension on the pole. To keep the pole from being pulled over by the wire, we install an anchor in the ground and attach steel wire between the pole and the anchor opposite of the side tension from the overhead wire.

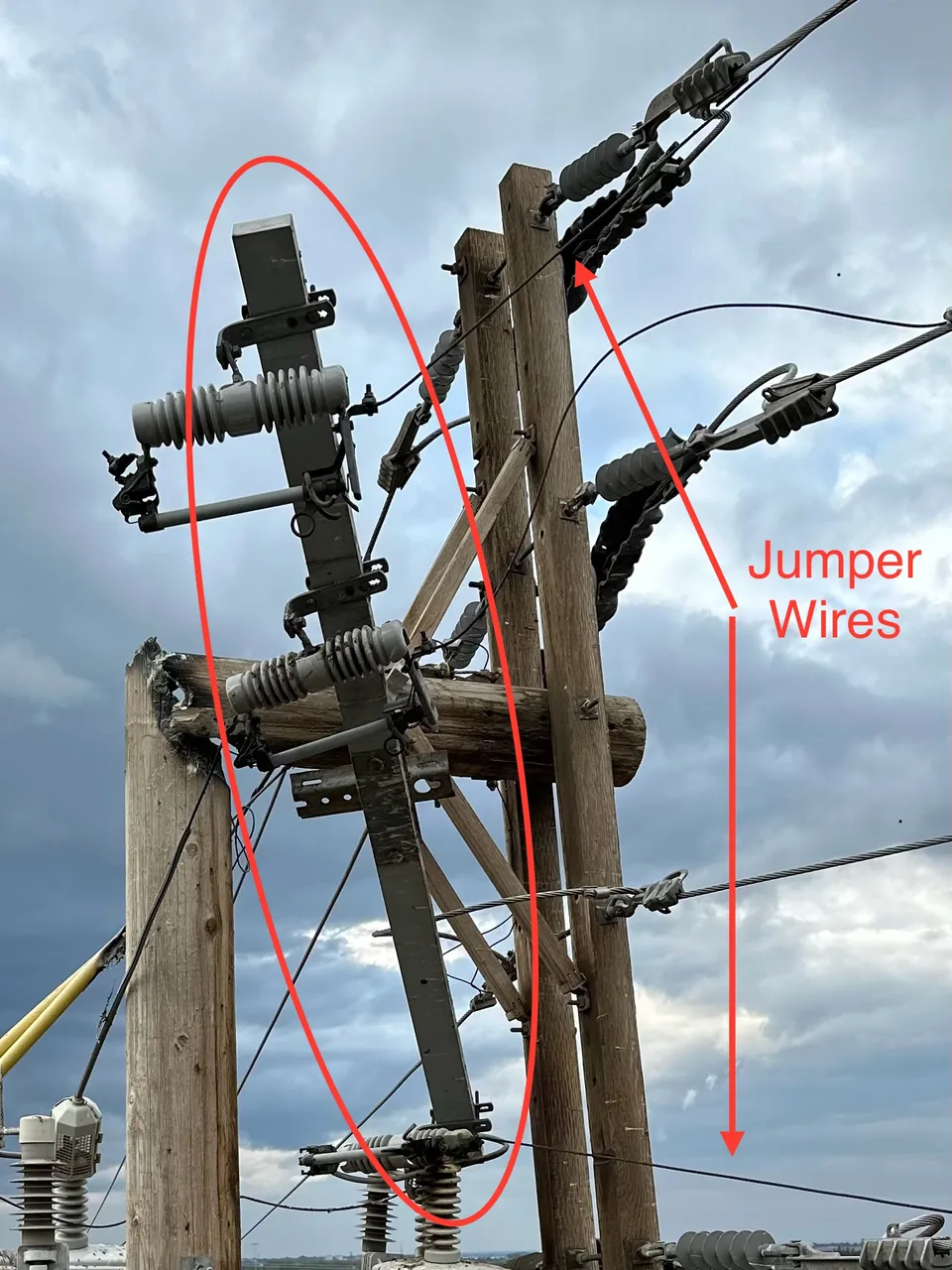

Looking up from the ground it looked like a tangled up mess. It was hard to tell what is actually holding the pole top in the air. A few of the jumper wires looked really tight, the fiberglass arm that holds the cut outs seems to be just floating there also… hmmmm…

We all put our heads together and came up with a game plan to untangle this mess. Looking at it from the ground tells a totally different story than what you see when you get up close. So it’s time to hop in the bucket truck and get up in there and see what is actually going on.

The steel guy wires going to the anchor are keeping the pole top from sling-shotting into the road. One of them is super tight. Where the pole burnt off, the top section looked like it just gently laid over and set down on the bottom section.

The top cross arms are resting on a secondary bushing of one of the transformers…

We better be careful with this one or else all hell might break loose…

The first thing we needed to get out of the way was the cutout arm. It was just kind of floating there being held up by the jumper wires. The bolts that hold it to the pole were missing…

As carefully as we could we cut the jumper wires and supported the cutout arm in order to get it out of the way. The end of the arm was resting on the transformer. Now that one hazard has been eliminated it’s time to get this pole top rigged up and out of the way.

We used the LineTruck winch and the winch from a bucket truck to control each side of the set of crossarms. Gently lifting and pulling the pole top back into the direction of the guy wire to get some slack in it. Once we got slack in the guy wire, we cut it. Things did jump around a bit once we made the cut but nothing too crazy.

Then we simply lowered the whole pole top to the ground. Due to the angle the pole top floated away from our work area. Also the weight of the pole top and the wire allowed the whole thing to set on the ground. That made it really nice to work on.

Now we can get to work getting the bank of transformers off of the pole and yanking the old pole out of the ground.

While a couple guys were taking care of that, another Lineman and I worked on getting the wire free from the pole top assembly. A few hoists and conductor grips and the wire was free from the old pole top and ready to be lifted up to the new pole once it was set

By this time it had gotten dark enough where we needed to turn on some work lights and throw on our headlamps. Now it’s time to get to work framing the new pole and getting it put in the ground.

Once the pole was in the ground, we used the winch from the LineTruck to pick each conductor up and onto the new pole and crossarm.

Then the Lineman in the air had to attach the conductors to the new arm and make sure the tension was correct going both directions. It was a bit of a battle due to the fact we went from 2 wood arms to one fiberglass but the boys got it handled nicely.

We were hoping to reuse the transformers but they were damaged and needed replaced. The pump that was powered by these transformers wasn’t a big deal but the rest of the feed lot needed power ASAP. So once we got the line energized it was time to clean up and head for the shop. A crew will bring out some new transformers the next day and get their pump going again.

That was a fun one!! Thanks for stopping in and checking out what us Lineman get to encounter when building and maintaining the electrical grid. Some repairs are pretty routine but others such as this take some thought and skill to get it done safely.

Time…

Your Random

Dose of...