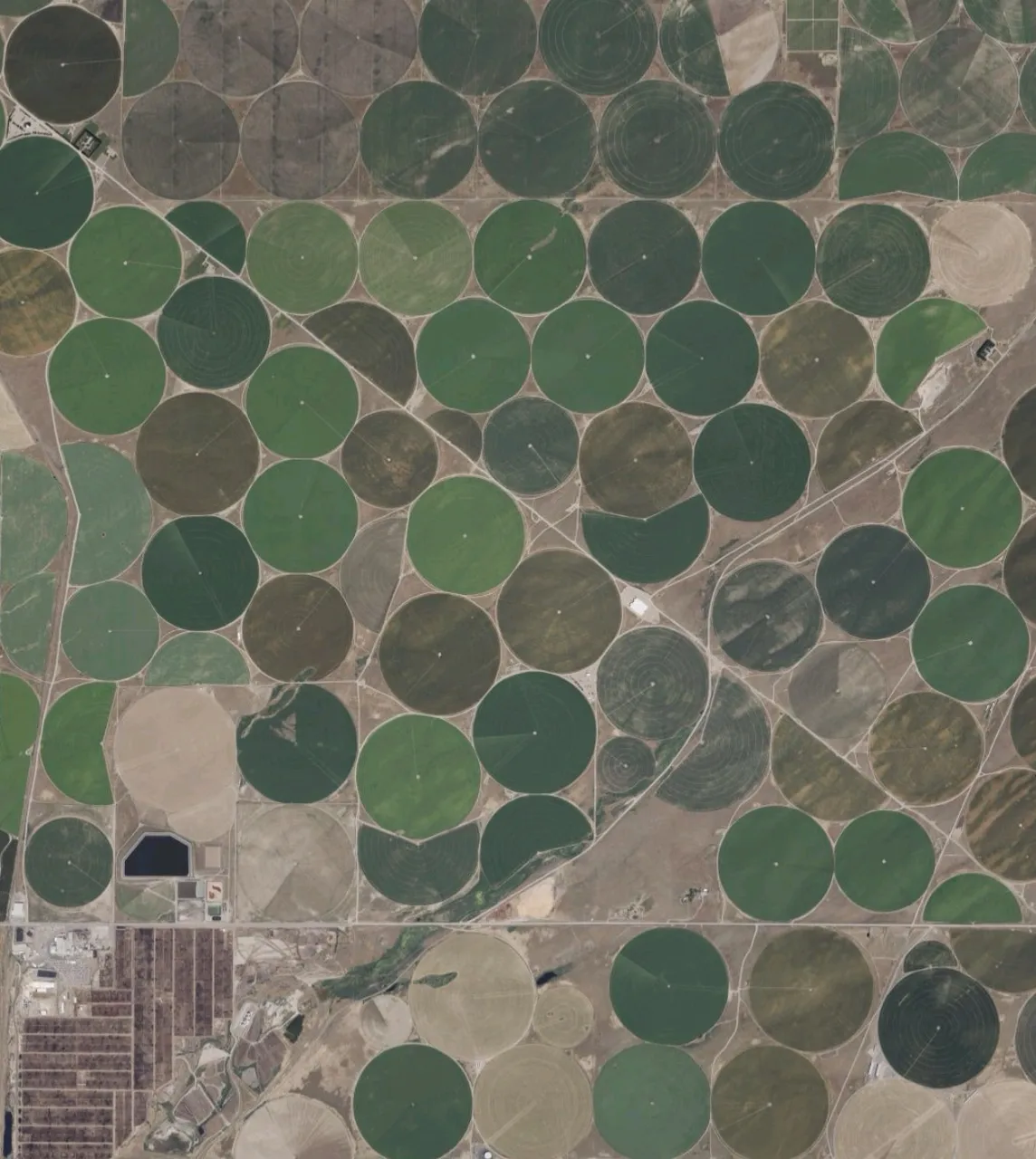

The local farmers are pretty good about letting us know what they come across when their power goes out. Whether it be a blown fuse, broken jumper wire, or the obvious wire on the ground or broken pole. This time the only info we got was a blown fuse feeding on a long tap that fed several irrigation pumps for the center pivot sprinklers. We just call them circles. Without GPS one could easily get turned around and lost in the middle of the night. A satellite image of the area does look pretty cool

screenshot of Apple Maps

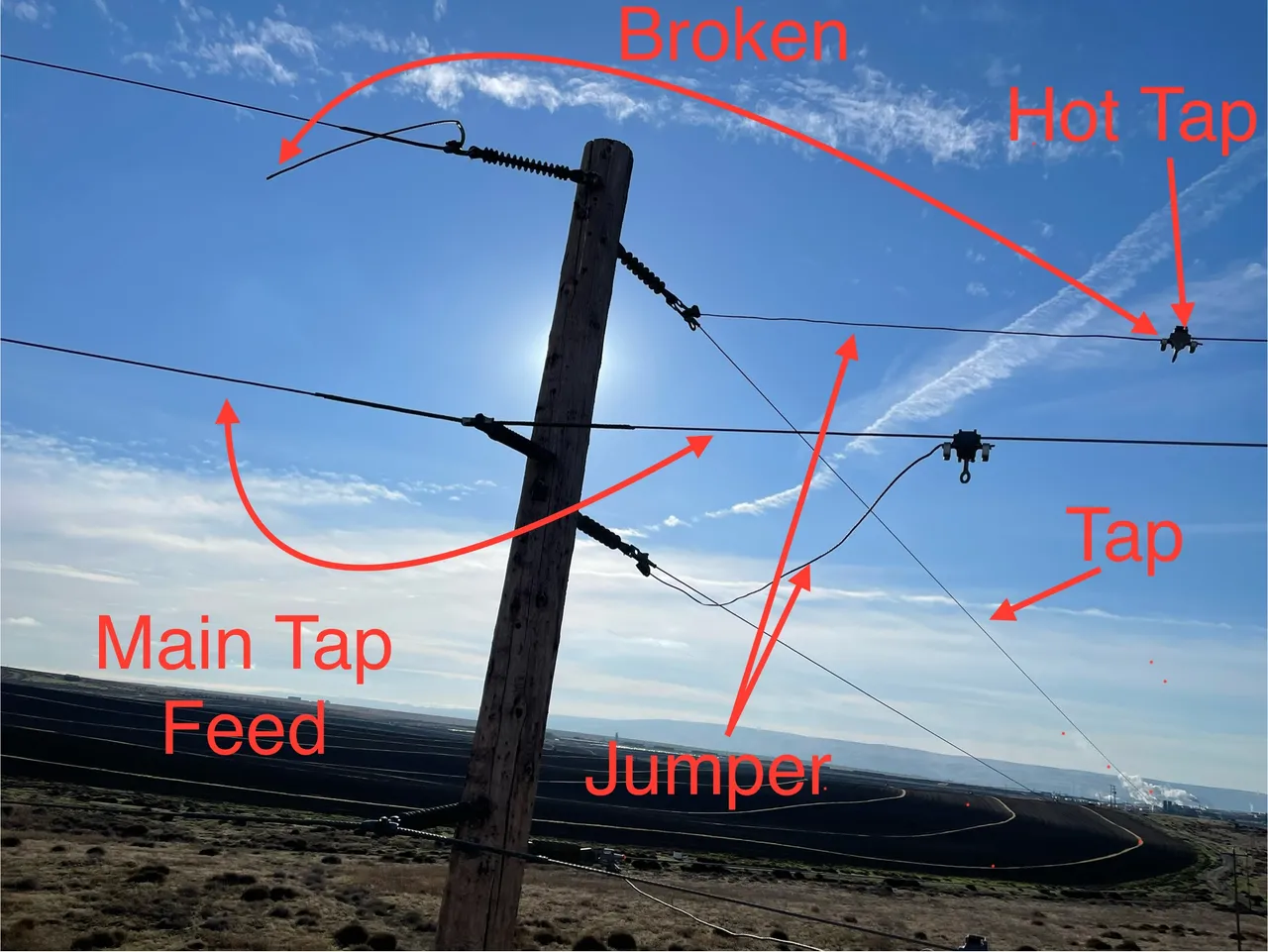

The crew was in the area and I was already headed that direction to handle some other small jobs and drop off some material to the crew. They followed the line in from the north and I came in from the south. They let me know that they had found wire laying on the ground. That wasn’t our only problem. I found this wire that broke but it was still up in the air.

If you don’t know what you are looking at, it’s kind of hard to tell what the hell is going on. Even when I first pulled up it took me a minute. I had to get out and walk around the pole and look at it from a different angle. So let me explain…

Clear as Mud… Right??

The main tap wire broke at the hot tap. The jumper wire that feeds the tap was holding up the main tap wire up in the air. When the wire broke it pulled the insulator over to the left. Being that I was the top wire in this vertical style construction, it sagged down and laid over the top of the other phase wire.

I wasn’t sure how much longer that hot tap was gonna hold the wire up. If I bumped it, would it let loose and hit the ground? It’s much easier to get the wire back together when it is still in the air.

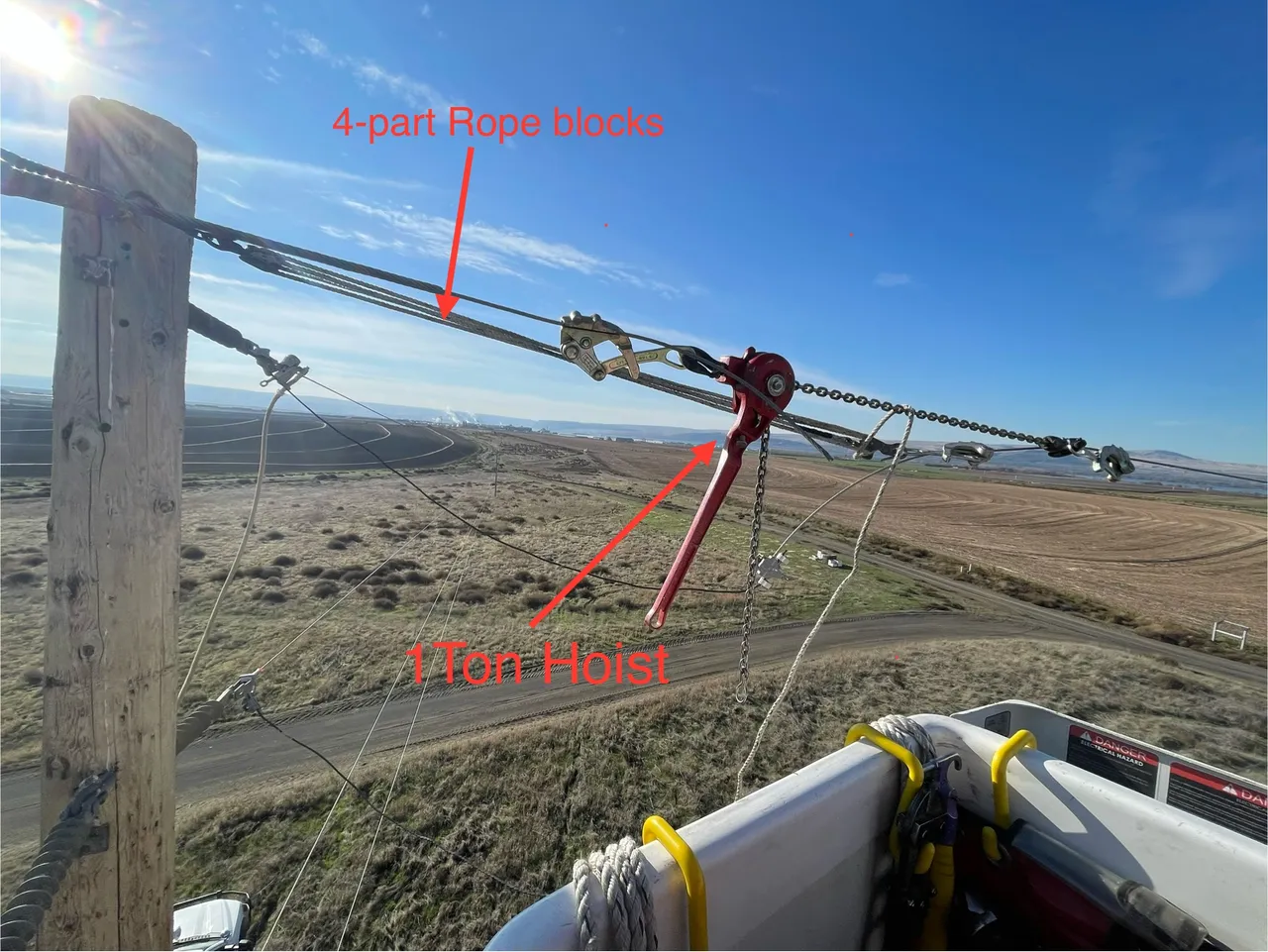

I grabbed my light weight 4-parted rope blocks and attached them to the pole first. Then stretched them out and hooked onto the wire beyond the hot tap with a conductor grip. These 4 parted blocks are alot longer than my 1 ton hoist. If I would have just used the hoist, I most likely would have ran out of hoist and the wire wouldn’t be up to sag. Then I would have to catch the wire off with a rope or another hoist and re-rig my hoist. Take the chain all the way out again and come up on the wire some more.

I pulled the wire up as far as I could with the rope blocks first, then did the final sag with the hoist.

Cut the damaged ends of the wire off and add in a chunk of wire. We use these automatic splices that work like a Chinese finger trap. Inside the cylinder there are spring loaded jaws that allow you to push the wire in but not pull it out. The harder you pull the harder the jaws bite down on the wire. I wish I would have taken a couple photos of the finished product but when you are doing all the work and your coworker is getting in a workout…

You only have time to laugh

Your Random

Dose of...