During the formation of Earth, molten iron sank to its centre to make the core. This took with it the vast majority of the planet's precious metals — such as gold and platinum. In fact, there are enough precious metals in the core to cover the entire surface of Earth with a four-metre thick layer.

Veins of gold, such as this one trapped in quartz and granite, may deposit when the high-pressure water in which they were dissolved suddenly vaporises during an earthquake. Scientists have long known that veins of gold are formed by mineral deposition from hot fluids flowing through cracks deep in Earth's crust.

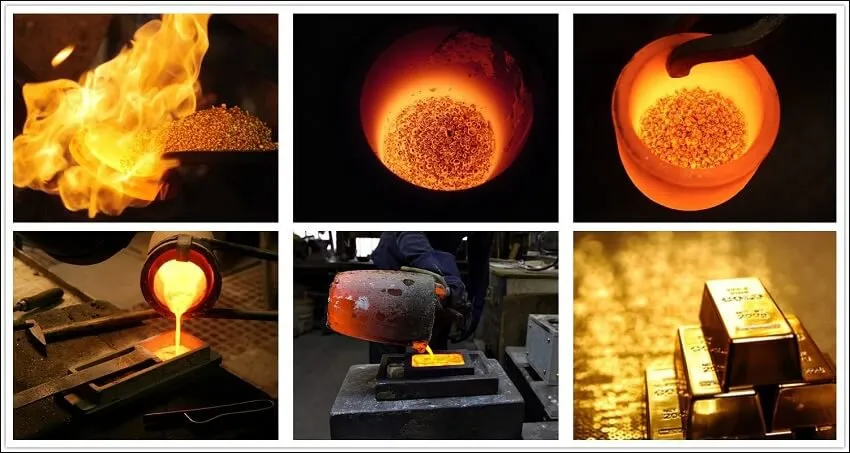

Cast gold bars are normally produced directly from gold that has been

melted.

However, the way in which melted gold is used in their manufacture can

vary.

This supplement describes in outline some typical methods for

manufacturing three types of cast bars:

(1) Large cast bars with approximate weights.

(2) Small cast bars (1000 g or less) with specific weights.

(3) Long flat cast bars, notably for the manufacture of minted bars.

It can be noted that most refiners apply their own variations. In addition,

many now automate some or all of the manufacturing process, some

through computer-controlled robots.

LARGE CAST BARS

As large cast bars (e.g. London Good Delivery ‘400 oz’ and COMEX

Division Good Delivery ‘100 oz’) are usually manufactured to an

approximate weight, the method of manufacture normally varies from that

adopted for small cast bars with a specific weight (e.g. exactly 1000 g).

Refined gold at the required purity for casting (i.e. pouring) into large bars

is usually taken directly in the form produced by the refining method (e.g.

in melted form following pyrometallurgical chlorination, or as cathode

deposits following electrolysis).

• The gold is melted in bulk in a large ʻholdingʼ crucible which

may contain as little as 450 oz or as much as 30,000 oz. Induction

furnaces are normally used to melt the gold.

• By tilting the “holding” crucible, a relatively small amount of gold,

between 450 oz and 2,000 oz, is then poured into a pre-heated

ʻtransferʼ crucible.

At this stage, dip samples (containing about 1/2 oz gold) for assaying

purposes may be taken, using a steel ladle or a glass vacuum tube.

• Using a gantry if necessary, melted gold in the ‘transfer’ crucible is

then poured through a soft gas flame into a pre-heated and dressed

bar mould (generally cast-iron) of the required size (e.g. 400 oz,

100 oz).

The mould, during pouring, is positioned on a balance. When the

balance records the required weight of gold, the pouring ceases.

• Within seconds following completion of the pouring, the mould is then

tilted so that the bar drops into a tank of water for immediate cooling.

This procedure is known as ʻquenchingʼ. Alternatively, the bar is

allowed to cool gradually in the mould through natural exposure to the

air.

• The bar is then placed on a table for cleaning with a soft cloth to

remove any stains, and weighed.

• Approved bars are then marked, where required, with the refiner’s

official stamp/certification mark, a serial number, the precisely

assayed purity of the batch of gold from which the bar was made, and

sometimes the weight.

Markings may be applied manually, working dies for each mark or group

of marks being hammered onto each bar individually. A template (i.e. a

stencil indicating the areas for marking) is normally used. Alternatively,

bars may be inserted into a press which applies some or all of the

markings simultaneously.

It can be noted that, in the case of London Good Delivery ‘400 oz’ bars,

the weight is not usually marked on the bar.

Assaying procedures during manufacture vary among refiners. Assays

are normally taken while the gold is in the ‘holding’ crucible and/or the

‘transfer’ crucible.

There you have it! How Gold is made! Let me know what you thought in the comments and be sure to upvote, follow and resteem!