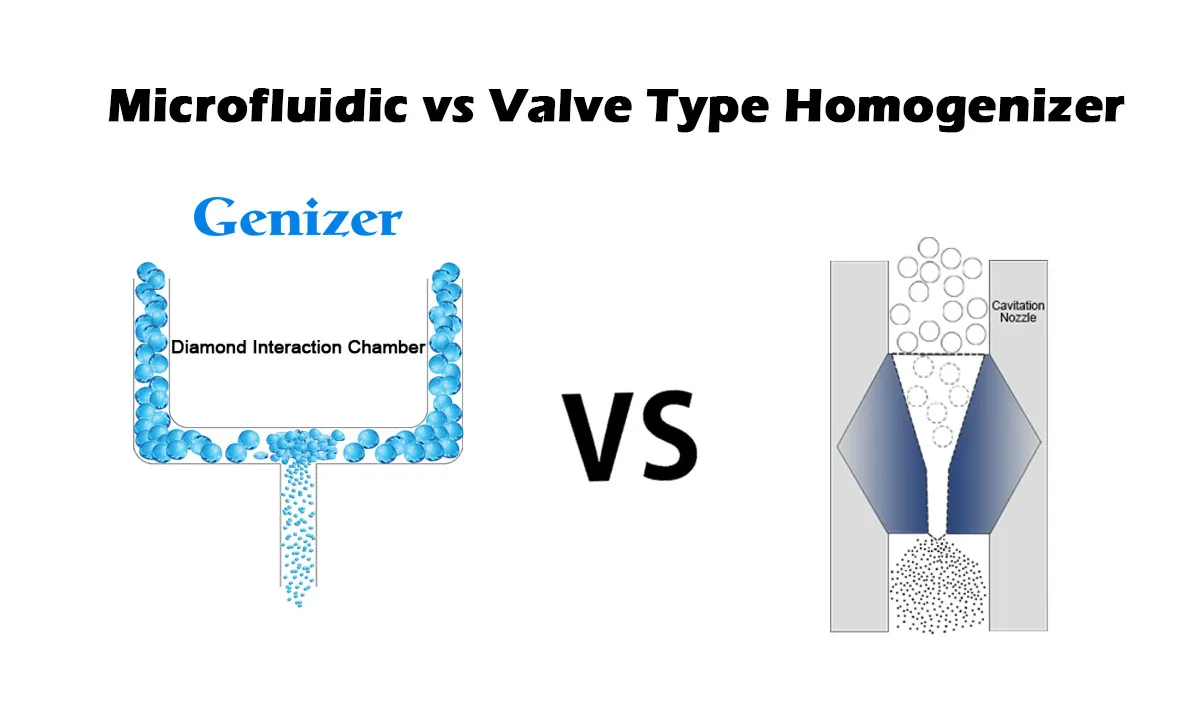

High-pressure homogenization is crucial in industries like pharmaceuticals, biotechnology, food, and cosmetics. The two most common types are valve-type and microfluidic jet homogenizers. Here’s a quick comparison to help you choose the best fit for your needs.

https://www.genizer.com/c/high-pressure-homogenizer_0360

Valve-Type High-Pressure Homogenizer

Valve-type homogenizers force liquids through a narrow valve at high pressure, creating shear forces to break down particles.

Advantages:

Cost-Effective: Lower initial cost.

Versatile: Widely used in emulsification, cell disruption, and suspensions.

Limitations:

Less Precision: Harder to achieve particles under 100 nm.

Higher Maintenance: Frequent wear and tear on mechanical parts.

Microfluidic Jet High-Pressure Homogenizer

Microfluidic jet homogenizers use micro-channels and cavitation to achieve ultra-fine particle sizes at higher pressures.

Advantages:

Ultra-Fine Particles: Achieves sub-100 nm particles, ideal for nanotechnology and drug delivery.

Low Maintenance: Fewer moving parts, reducing downtime.

Limitations:

Higher Cost:More expensive upfront.

Slower Throughput: May be less efficient for large batches.

How to Choose

Particle Size: For ultra-fine particles (sub-100 nm), choose microfluidic jet.

Batch Size: Valve-type is better for larger batches, while microfluidic jet is ideal for smaller, precise batches.

Cost: Valve-type homogenizers are more budget-friendly but microfluidic jet offers long-term value due to precision.

Valve-type homogenizers are ideal for general applications and large batches, while microfluidic jet homogenizers excel in precision, making them perfect for high-end pharmaceuticals and nanotechnology. For superior results in ultra-fine emulsions and nanoparticles, Genizer’s * High Pressure Homogenizer * offer minimal maintenance and high performance.