created with Bing image creator

How to turn electronic waste into gold the easy way?

What having gold means

Gold as an asset is a much sought after commodity. In the list of assets by market cap Gold tops the charts and sits right at the top.

Gold is the king of precious metals and extremely rare to find. That is why the central banks of so many countries are in a race to stack up as much gold as possible to boost their sagging economies.

The lure of this precious metal has existed since human civilization discovered Gold. Not only did gold find its use as a means of store of value, Jewelry and bullion.

Its excellent conducting properties has made it the metal of choice in the electronic industry and computers as well.

A significant usage of Gold has been in building computer motherboard, RAM's and other computer components.

Though it is expensive and highly useful it finds its existence in tiny proportions in the computer components.

Since these components are mass produced under controlled environments in factories therefore applying gold as micro films is viable.

Every computer and electronic component has a finite life

Once the device has lived its life it retires due to old age and is replaced by faster, upgraded more efficient technology powered components and boards.

This leads to a pile of e-waste.

On an individual level these boards or components have a tiny amount of gold and other precious metals however collectively in a pile they can offer a significant amount of gold.

The tricky part is extracting gold from these components as the recycling of this e-waste is a toxic, expensive and time consuming process kicking up debate if it is worth the effort and resources to take out gold from this e-waste. The process has been lagging and waiting for the arrival of more cost effective and environmentally friendly technology.

The tech to recover gold from e-waste is here

Researchers at ETH Zurich have created a process of recovering precious metals from e-waste.

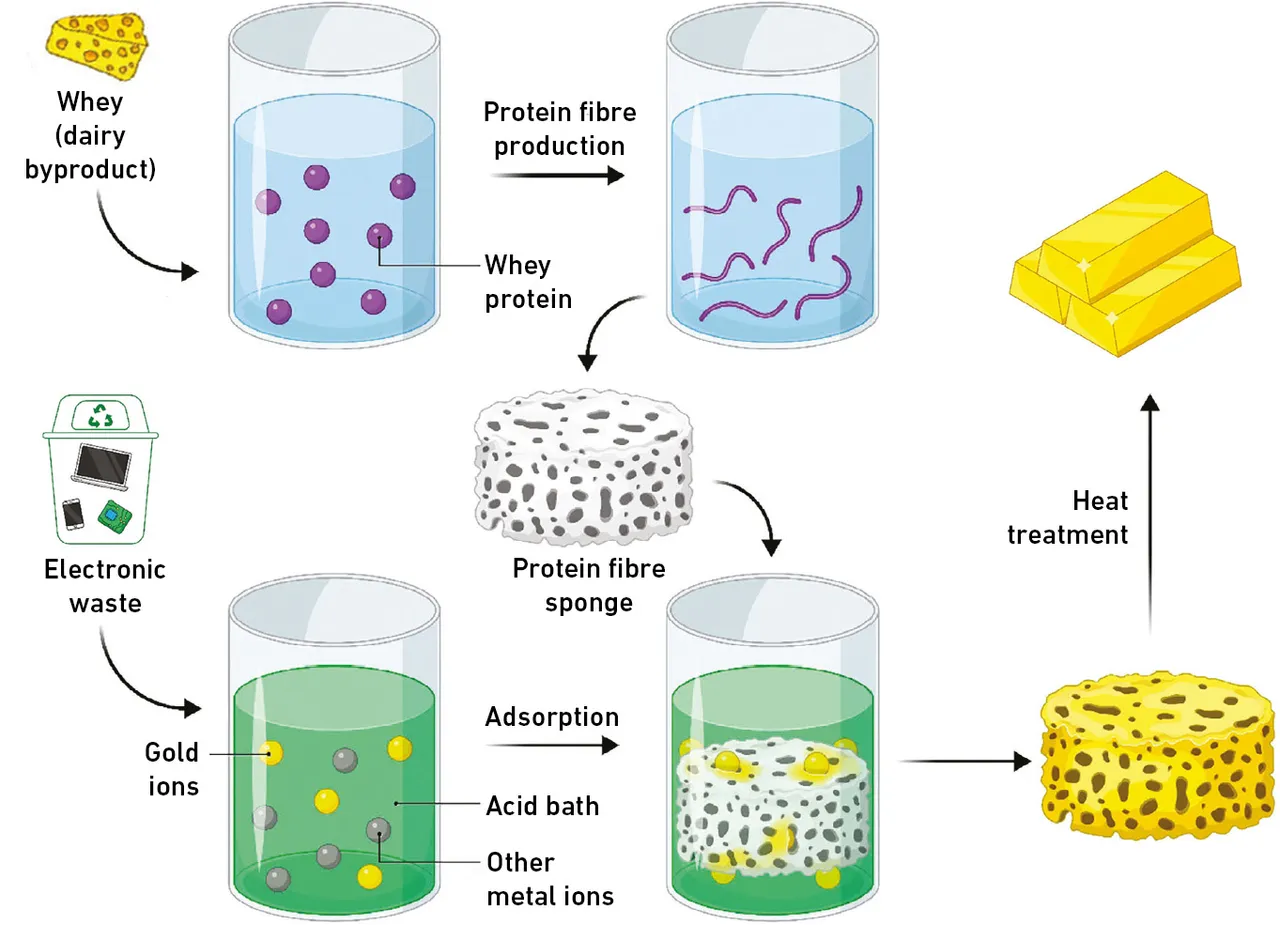

This method is based on the use of a specially designed sponge that is made up of protein fibrils.

Interestingly this Fibril protein sponge has been developed by the scientists by using a food industry byproduct.

This industry byproduct is whey.

The task which has eluded scientists for a long time however Professor Raffaele Mezzenga who works with the Department of Health Sciences and Technology at ETH Zurich and his team has accomplished this seemingly impossible feat.

To the team's credit goes the development of a process that has achieved a task that seemed so hard to achieve.

The research done by the team has discovered that

- This special fibril protein created by the team can be very useful in extracting gold from e waste that is otherwise considered quite useless.

- In their experiments of 20 computer motherboards the team was able to recover 22 karat gold weighing 450 mg

- The use of industrial byproducts and wastes makes the process cost effective and viable.

Both computer components and scrapped mobile phones can contain cobalt, copper and even gold. Since the gold prices are rising due to increasing demand therefore researchers and scientists have been looking to extract precious metals from the tons of e-waste that is all around us.

Meet Mohammad Peydayesh who made it possible

Working as a senior scientist at ETH Zurich, Mohammad Peydayesh has been working on selective gold absorption.

Mezzenga and his team have developed a process in which they have denatured whey protein under an acidic condition under high temperature conditions.

This initiates the process of turning the nanofibril protein into a gel-like substance.

By drying this gel the team at ETH Zurich has turned the gel into a sponge.

Next the team used twenty old motherboards that they extracted the electronic parts from the main motherboards.

By immersing into an acid bath and this ionized the metals present in the boards.

Next when the team placed the protein nanofibril sponge into the ionized solution, they found that the gold ions adhered to the protein fibres.

Even though other metal ions also have a tendency to adhere to the sponge, gold ions have a more efficient adherence to the fibre sponge.

Next the sponge was heated and this process reduced the gold ions into bigger gold flakes.

These flakes were subsequently melted by the team into a gold nugget.

Upon analysis the team discovered the composition of the nugget to be 91% gold and the 9% copper.

The weight of the nugget is 450 mg that was extracted from 20 computer motherboards.

The finding of the team was published in a research paper that can be read here

The Economic viability of gold extraction from e waste

The process carried out by Mezzenga and his team demonstrates a process that has fifty times less energy requirements as compared to the gold that gets recovered.

Getting the tech ready for the industry

The research team is working on a process to adapt the technology that may be used on an industrial scale.

The team is working on ways to extract gold from other sources like electroplated gold surfaces.

The researchers of the team are also looking at ways to develop the protein from protein rich wastes and by products from other food industries.

source