In the career of chemical engineering one of the main subjects of study together with thermodynamics is the transport phenomena where through processes there is a net transfer or transport of matter, energy or linear moment in large or macroscopic quantities, in this case We will treat the transfer of heat or energy fundamental principle of our lives.

Heat transfer.

The science of thermodynamics deals with quantitative transitions and rearrangements of energy as heat in the bodies of matter. The science of heat transfer is related to the ratio of heat exchange between hot and cold bodies called source and receiver. When a liter of water is vaporized or a pound of steam condenses, the energy change in the two processes is identical. The speed at which any of these processes can be progressed with an independent source or receiver is, however, inherently very different. Generally, vaporization is a phenomenon much faster than condensation.

Mechanisms of heat transfer

There are three different ways in which heat can pass from the source to the receiver, even when many of the applications in engineering are combinations of two or three. These are, conduction, convection and radiation.

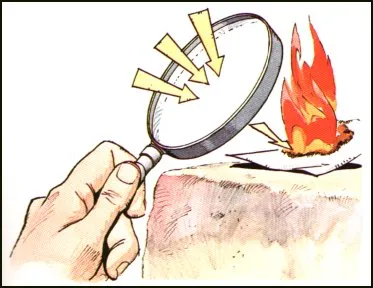

Conduction

It is the transfer of energy by physical contact due to a temperature gradient between them, without appreciable displacement of the body's particles. The medium can be solid, liquid or gaseous, although in pure liquids and gases pure conduction is given if the possibility of convection is excluded. The amount of heat that is transferred by conduction is given by the Fourier law. This law states that the speed of heat conduction through a body per unit cross section is proportional to the temperature gradient that exists in the body.

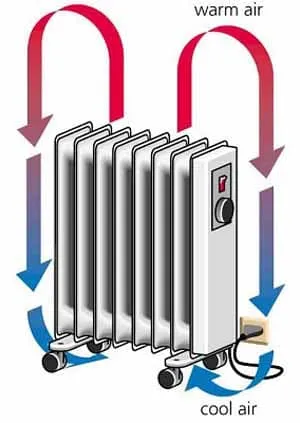

Convection

It is the transfer of heat from one point to another within a fluid (gas or liquid) by mixing one portion of the fluid with another. There are two mechanisms of heat transfer by convection, called forced convection and natural convection. The amount of heat transferred by convection is governed by Newton's law of cooling.

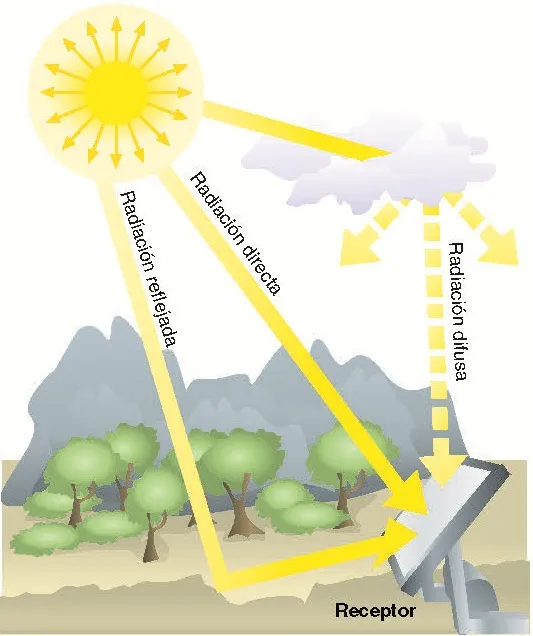

Radiation

It is the transfer of heat from one body to another by the movement of electromagnetic waves through space, even when there is a vacuum between them. The clearest example is that of the sun that with the great amount of energy that radiates daily is used as a source of electricity generation

Heat transfer processes.

Heat transfer has been described as the study of the speeds at which heat is exchanged between heat sources and receivers, usually treated independently. The processes of heat transfer are related to the reasons for heat exchange, such as those that occur in heat transfer equipment, both in mechanical engineering and in chemical processes. This approach emphasizes the importance of temperature differences between the source and the receiver, which is, after all, the potential by which the heat transfer takes effect.

A typical problem of heat transfer processes involves the amounts of heat that must be transferred, the reasons to which they can be transferred due to the nature of the bodies, the potential difference, the extension and arrangement of the surfaces that separate the source and the receiver, and the amount of mechanical energy that must be dissipated to facilitate heat transfer. Since heat transfer considers an exchange in a system, the loss of heat by one body should be equal to the heat absorbed by another within the confines of the same system

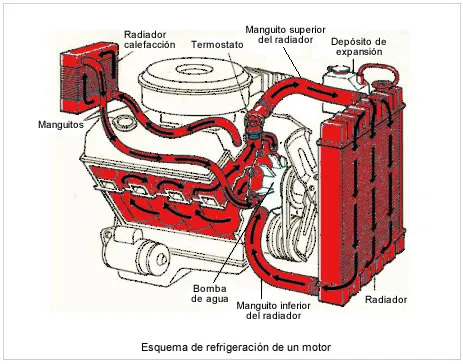

The heat exchanger

It is a device designed to transfer heat between two fluids, these being in contact or separated by a solid barrier. These are essential components in air conditioning or refrigeration systems, air conditioning, energy production and chemical processing. To easily understand the operation of the heat exchanger, we can take as a reference the radiator of any vehicle. The engine heats the cooling fluid. The latter is cooled by contact with air currents, thus reducing the temperature of the first after circulating inside.

Uses of the heat exchanger

The heat exchangers are used for the following uses:

- Raise the temperature of a fluid thanks to a hotter one.

- Refreshing one fluid using another with lower temperature.

- Bring to the boiling point to a fluid by the action of a second with higher temperature.

- Condensing gases using cold fluids.

- Boil a certain fluid while condensing another hot gas.

Types of heat exchanger

Different criteria can be taken into account when classifying the different types of heat exchangers. If we analyze the degree of contact between the fluids involved, they can be grouped into two large blocks:

Direct contact heat exchanger

In the direct contact exchangers the heat transfer is carried out by means of a physical mixture of the fluids involved in the process. The two currents are easily separable after the exchange of energy. The cooling towers are direct contact exchangers, which are responsible for removing heat from a stream of hot water, by means of dry and cool air circulating in the system.

Indirect contact heat exchanger

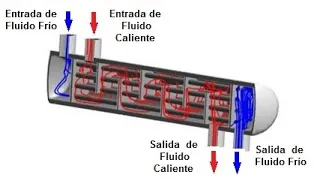

In the mechanisms of indirect action, on the contrary, there is no direct contact between the fluids, they do not get to mix. They are separated by solid elements, by a space and, even, by a lapse of time. The heat is transferred by convection or conduction through the separating wall. The indirect contact heat exchangers can be concentric tubes or double tubes, shell and tubes, plates, compact, regenerators.

The double tube equipments are the simplest that exist. They are made up of two concentric pieces of different diameter. One of the fluids circulates inside the smallest and the other flows through the annular space between the two tubes. The shell and tube heat exchangers are widely used in the industry. As the name indicates, its basic components are a shell and a multitude of tubes. For its part, the plate systems are assembled on the basis of a succession of metal sheets, all armed in a frame and separated by joints fixed to a steel shell. The connection between the sheets allows a certain fluid to flow between the first and the second, between the second and the third, and so on.

According to the Configuration / Construction, you can exempt other types of exchangers

Shell and tube heat exchangers

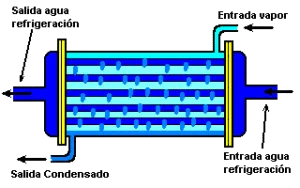

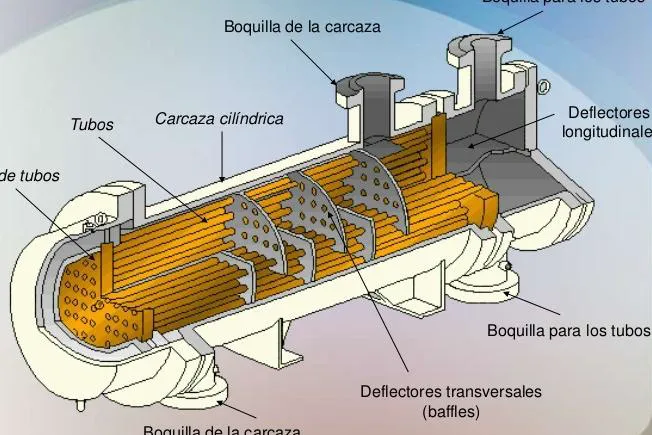

They are composed of cylindrical tubes, mounted inside a casing also cylindrical, with the axis of the tubes parallel to the axis of the casing. One fluid circulates inside the tubes, and the other on the outside (fluid on the side of the casing). They are the most widely used type of heat exchangers in the industry.

There are 3 basic types of shell and tube exchangers depending on the method used to keep the tubes inside the shell.

- Fixed Type or Fixed Tube or Fixed Head Plate Exchanger

- U-shaped exchangers

- Floating head exchangers

1. Fixed Type or Fixed Tube or Fixed Head Plate Exchanger

The equipment has straight tubes, secured at both ends in tubes plates welded to the shell. In this type of construction, it is sometimes necessary to incorporate an expansion joint or expansion of the gaskets due to the differential expansion of the shell and the tubes. The tube bundle can not be removed for inspection and cleaning, however, the head on the side of the tubes, the gaskets, the channel cover among others, are accessible for maintenance and replacement of the parts. The housing can be cleaned by backwash or chemically. Fixed head exchangers are used in service where the fluid in the housing is clean as water vapor, coolant, gases and certain type of cooling water.

)

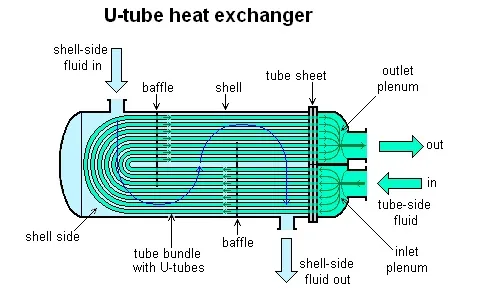

)2. U-shaped heat exchangers

It uses U-shaped tubes, with both ends of the tubes attached to a plate of simple tubes. The bundle of tubes can be removed from the housing for inspection and cleaning but the mechanical internal cleaning of the tubes and their replacement is difficult, therefore, they are used in Clean Services and also at High Pressure since they are more economical than those of Fixed plate in this application.

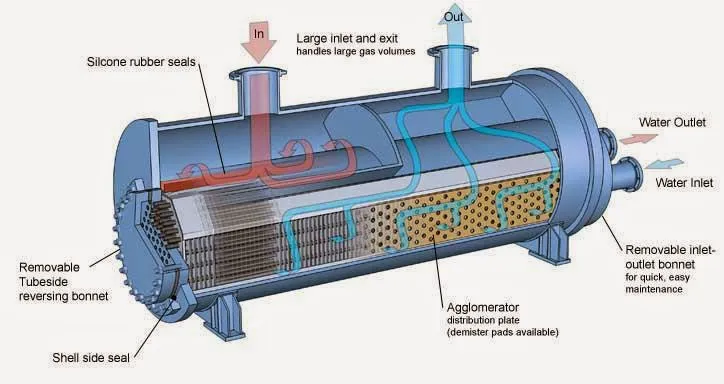

3. Floating Head Exchangers

Like fixed head units, they have two tube plates, but only one of them is welded to the housing and the other moving freely, which avoids differential expansion problems. The tube bundle can be removed for maintenance and mechanical cleaning of the casing and pipes both externally and internally. The design is more expensive (about 25%) than the fixed head design and is appropriate for services associated with high temperatures and pressures, but limited to those services where the leakage of fluid contained in the housing is tolerable.

Air Coolers

Air coolers consist of one or more axial flow fans, relatively low speeds and large diameters, which force or induce air to flow through a bank of tubes, usually with fins.

Double Tube Exchangers

They consist of one or more concentric tubes of another U-shaped tube that acts as a carcass. Most have longitudinal fins on the outer surface of the tubes. They are low cost units, resistant and can be easily dismantled for cleaning, removing the lid, dismantling both or front closures and removing the heat transfer element.

Plate Exchangers

In these units, the heat transfer surface is constructed of metal plates. These plates can be of smooth, corrugated or channeled surfaces.

For more information visit the following links.