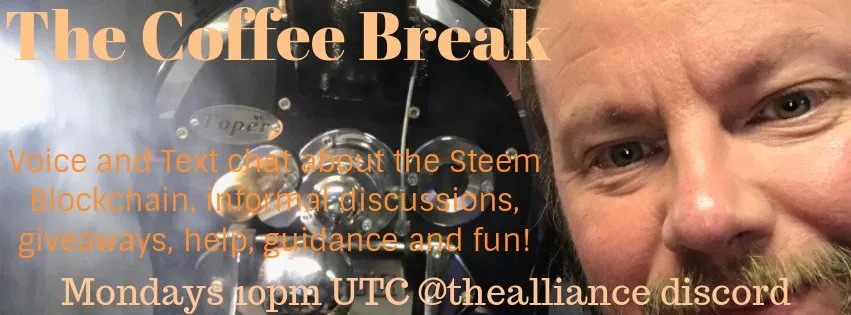

Since my new roaster arrived on Friday I have been puzzling about how to get the green coffee bean hopper mounted on top of it, the hopper itself weighs well over 40kg and needs to slot in on the top - follow the chain down in the picture above and you will see the circular mounting the hopper needs to fit into.

This is the hopper upside down in it's protective wrapping, you can see the silver bit just above the rope needs to slide into the mounting on the roaster. The plan is to rope this hopper and attach it to the winch we already have for moving things between floors - but the winch chain is confined to the wooden cage by the wall - and I need this to land directly on the top of the roaster...

The winch above moves back and forth - because the cage it brings up needs to move from the hole onto the solid floor to be emptied and filled. So utilising 100% of my brain cell capacity I worked out if I make a hole in the floor / ceiling - I can get the winch to be directly above the roaster where the hopper needs to fit - Impressive. So moving the monster roaster with a pallet truck I lined it up with the winch chain and as close to the wooden cage as I could - and marked where the winch cable should fall through the ceiling.

First hole cut, utilising entirely non HSE approved folding ladders which if I balanced just at the top I could drill two bore holes and then jig saw the slat out - oh didn't have time to find the safety goggles but what's a bit of saw dust in your eyes when if you fall off the ladders nobody is around to hear you scream and if you go outside you'll get a killer flu.

Observe my Proof of Brain (cell) - the winch cable now dangles exactly over the position on the roaster I need to land the hopper on. It wasn't as easy as I had planned, after removing the lower slat I wanted to drill up through the upper floor - but the gap between them is well over a foot and the drill bit was not long enough. So plan B was to measure from the far right edge below and match above and drill down - I did that and made a hole exactly centre to the lower gap. So I used the slat I removed below for reference and matched it to the middle of my test hole - and then cut either side - almost perfect match! Even better luck the upper floor has two set's of floor boarding which are off set against each other. So after cutting the same gap above I removed one piece, but found below it another solid board. So I cut that long ways but leaving a centimetre each side -which means the top board can be replaced to cover the hole.

So I'm all ready to rope up the top hopper and hopefully position it on top of the roaster, and my new modified winch position will make lifting the cooling tray and loader off their iron pallets easy - who even needs a fork lift when you have a winch and a jig saw!

Active HIVE Witness alongside @derangedvisions, if you appreciate the effort and work we put into the HIVE blockchain please consider giving us a Witness vote.

Proud sponsor with @derangedcontests of @brosino , free to play and cash out HIVE rewards, head to Brosino Website now and start playing.

I distribute coffee roasting machines and also espresso coffee machines and roast my own Speciality Coffee Range. being one of the premium coffee suppliers Yorkshire including a wide range of filter coffee sachets. Finally I have a dedicated website to my Artisan small batch roasted coffee featuring roast and post packs and super easy coffee subscriptions.

The Coffee Break Discord Voice Chat Show, in @thealliance Mondays 10pm UTC hosted by @c0ff33a and @enginewitty